ASTM B16.11 Forged Fittings Diemntions – Threaded & Socket Weld

ASTM B16.11 Forged Fittings Dimensions, Forged Threaded and Socket Weld Fittings in the size range 1/2” to 4” and in pressure ratings Class

ASTM B16.11 is the international standard used in the manufacturing of Forged Fittings which include two types that are Forged Threaded Fittings and Forged Socket Weld Fittings. These High-Pressure Fittings are available in Various Materials like Stainless Steel, Carbon Steel, High Nickel Allys, and more.

It is produced in the Size range of 1/2” to 4”, and in pressure ratings Class 2000, 3000, 6000, and 9000. Pressure rating classes also differ in Threaded and Socket Weld Fittings, Class 2000, 3000, and 6000 for threaded fittings and Class 3000, 6000, and 9000 for socket-weld fittings.

Forged pipe fittings are manufactured by forging and machining solid steel and are available in various shapes like Elbow, Bushing, Cap, Cross, Coupling, Plug, Tee, End Cap, Union, Reducer, Reducer Insert, Boss, Nipple, Adapter, Outlet. It is used for associating or connecting pipes, pumps, valves, & other equipment to create a piping system below the size 2 or 4 inches in diameter.

Socket weld fittings connect to pipes by fillet welds and threaded fittings by screwing pipe onto the fittings. Normally Class 3000 fittings are used for pipes in schedule 80/XS; Class 6000 for pipes Sch. 160; Class 9000 fittings for pipes with larger wall thickness (XXS).

Creative Piping Solutions is one of the top manufacturers of High Pressure Forged Pipe Fittings in India. We are authorized Suppliers and Exporters of Threaded and Socket Weld Fittings in South Africa, Malaysia, Singapore, Qatar, Italy, Philippines, Australia, and Dubai, UAE.

| Class of Fitting |

Type of Fitting |

SCH No. | Wall Designation |

|---|---|---|---|

| 2000 | Threaded | 80 | XS |

| 3000 | Threaded | 160 | – |

| 6000 | Threaded | – | XXS |

| 3000 | Socket-Welding | 80 | XS |

| 6000 | Socket-Welding | 160 | – |

| 9000 | Socket-Welding | – | XXS |

Above Table: correlation of ASME B16.11 fittings Class with schedule number or wall designation of pipe for calculation of ratings.

ASME B16.11 Standard Scope:

This standard contains dimensions, pressure-temperature ratings, markings, tolerances, and material requirements for forged fittings. Custom-design forged fittings with special dimensions, threads, or counterbores may be made by agreement between the manufacturer and purchaser. All dimensions tables are given below.

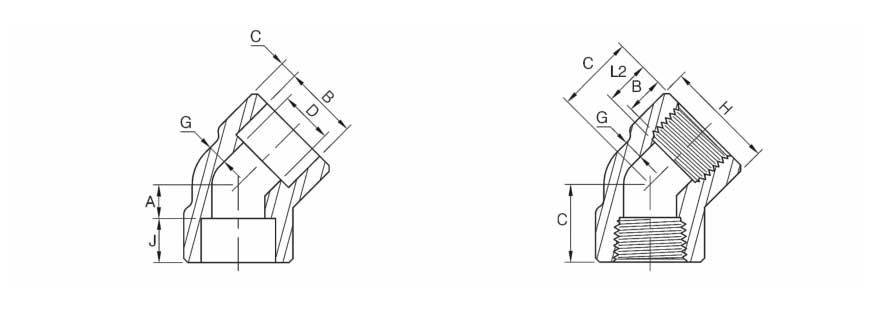

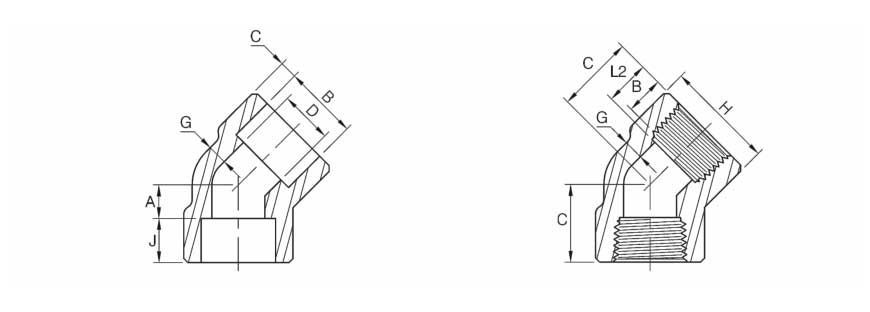

ASME B16.11 45 Degree Elbow Dimensions

Dimensions in Millimeters.

| Socket Welding | |||||||

| DN | Nom. Pipe Size |

B(2) |

C(1) | D(2) | A(2) |

G (Min) |

J (Min) |

| (Avg) I (Min) | |||||||

3000Lb

| 6 | 1/8 | 10.8 | 3.18 | 3.18 | 6.9 | 8.0 | 2.41 | 9.5 |

| 8 | 1/4 | 14.2 | 3.78 | 3.30 | 9.3 | 8.0 | 3.02 | 9.5 |

| 10 | 3/8 | 17.6 | 4.01 | 3.50 | 12.6 | 8.0 | 3.20 | 9.5 |

| 15 | 1/2 | 21.8 | 4.67 | 4.09 | 15.8 | 11.0 | 3.73 | 9.5 |

| 20 | 3/4 | 27.2 | 4.90 | 4.27 | 21.0 | 13.0 | 3.91 | 12.5 |

| 25 | 1 | 33.9 | 5.69 | 4.98 | 26.7 | 14.0 | 4.55 | 12.5 |

| 32 | 1-1/4 | 42.7 | 6.07 | 5.28 | 35.1 | 17.5 | 4.85 | 12.5 |

| 40 | 1-1/2 | 48.8 | 6.35 | 5.54 | 40.9 | 20.5 | 5.08 | 12.5 |

| 50 | 2 | 61.2 | 6.93 | 6.04 | 52.5 | 25.5 | 5.54 | 16.0 |

| 65 I | 2-1/2 | 73.9 | 8.76 | 7.67 | 62.7 | 28.5 | 7.01 | 16.0 |

| 80 | 3 | 89.8 | 9.52 | 8.30 | 78.0 | 32.0 | 7.62 | 16.0 |

| 100 | 4 | 115.2 | 10.69 | 9.36 | 102.3 | 41.0 | 8.56 | 19.0 |

6000Lb

| 6 | 1/8 | 10.8 | 3.96 | 3.43 | 4.0 | 8.0 | 3.15 | 9.5 |

| 8 | 1/4 | 14.2 | 4.60 | 4.01 | 6.4 | 8.0 | 3.68 | 9.5 |

| 10 | 3/8 | 17.6 | 5.03 | 4.37 | 9.2 | 11.0 | 4.01 | 9.5 |

| 15 | 1/2 | 21.8 | 5.97 | 5.18 | 11.8 | 12.5 | 4.78 | 9.5 |

| 20 | 3/4 | 27.2 | 6.96 | 6.04 | 15.6 | 14.0 | 5.56 | 12.5 |

| 25 | 1 | 33.9 | 7.92 | 6.93 | 20.7 | 17.5 | 6.35 | 12.5 |

| 32 | 1-1/4 | 42.7 | 7.92 | 6.93 | 29.5 | 20.5 | 6.35 | 12.5 |

| 40 | 1-1/2 | 48.8 | 8.92 | 7.80 | 34.0 | 25.5 | 7.14 | 12.5 |

| 50 | 2 | 61.2 | 10.92 | 9.50 | 42.9 | 28.5 | 8.74 | 16.0 |

9000Lb

| 15 | 1/2 | 21.8 | 9.35 | 8.18 | 6.4 | 15.5 | 7.47 | 9.5 |

| 20 | 3/4 | 27.2 | 9.78 | 8.56 | 11.1 | 19.0 | 7.82 | 12.5 |

| 25 | 1 | 33.9 | 11.38 | 9.96 | 15.2 | 20.5 | 9.09 | 12.5 |

| 32 | 1-1/4 | 42.7 | 12.14 | 10.62 | 22.8 | 22.5 | 9.70 | 12.5 |

| 40 | 1-1/2 | 48.8 | 12.70 | 11.12 | 28.0 | 25.5 | 10.15 | 12.5 |

| 50 | 2 | 61.2 | 13.84 | 12.12 | 38.2 | 28.5 | 11.07 | 16.0 |

1. Average socket Wall Thickness around the periphery be no less than the listed values. The minimum values are permitted in localized areas.

Dimensions in Millimeters.

| Threaded | ||||||

| DN | Nom. Pipe Size |

Length of Thread. (Min) |

C | G (Min) |

H | |

| B(2) | L2(2) | |||||

2000Lb

| 6 | 1/8 | 6.4 | 6.7 | 17 | 3.18 | 22 |

| 8 | 1/4 | 8.1 | 10.2 | 17 | 3.18 | 22 |

| 10 | 3/8 | 9.1 | 10.4 | 19 | 3.18 | 25 |

| 15 | 1/2 | 10.9 | 13.6 | 22 | 3.18 | 33 |

| 20 | 3/4 | 12.7 | 13.9 | 25 | 3.18 | 38 |

| 25 | 1 | 14.7 | 17.3 | 28 | 3.68 | 46 |

| 32 | 1-1/4 | 17.0 | 18.0 | 33 | 3.89 | 56 |

| 40 | 1-1/2 | 17.8 | 18.4 | 35 | 4.01 | 62 |

| 50 | 2 | 19.0 | 19.2 | 43 | 4.27 | 75 |

| 65 | 2-1/2 | 23.6 | 28.9 | 52 | 5.61 | 92 |

| 80 | 3 | 25.9 | 30.5 | 64 | 5.99 | 109 |

| 100 | 4 | 27.7 | 33.0 | 79 | 6.55 | 146 |

3000Lb

| 6 | 1/8 | 6.4 | 6.7 | 17 | 3.18 | 22 |

| 8 | 1/4 | 8.1 | 10.2 | 19 | 3.30 | 25 |

| 10 | 3/8 | 9.1 | 10.4 | 22 | 3.51 | 33 |

| 15 | 1/2 | 10.9 | 13.6 | 25 | 4.09 | 38 |

| 20 | 3/4 | 12.7 | 13.9 | 28 | 4.32 | 46 |

| 25 | 1 | 14.7 | 17.3 | 33 | 4.98 | 56 |

| 32 | 1-1/4 | 17.0 | 18.0 | 35 | 5.28 | 62 |

| 40 | 1-1/2 | 17.8 | 18.4 | 43 | 5.56 | 75 |

| 50 | 2 | 19.0 | 19.2 | 44 | 7.14 | 84 |

| 65 | 2–1/2 | 23.6 | 28.9 | 52 | 7.65 | 102 |

| 80 | 3 | 25.9 | 30.5 | 64 | 8.84 | 121 |

| 100 | 4 | 27.7 | 33.0 | 79 | 11.18 | 152 |

6000Lb

| 6 | 1/8 | 6.4 | 6.7 | 19 | 6.35 | 25 |

| 8 | 1/4 | 8.1 | 10.2 | 22 | 6.60 | 33 |

| 10 | 3/8 | 9.1 | 10.4 | 25 | 8.98 | 38 |

| 15 | 1/2 | 10.9 | 13.6 | 28 | 8.15 | 46 |

| 20 | 3/4 | 12.7 | 13.9 | 33 | 8.53 | 56 |

| 25 | 1 | 14.7 | 17.3 | 35 | 9.93 | 62 |

| 32 | 1-1/4 | 17.0 | 18.0 | 43 | 10.59 | 75 |

| 40 | 1-1/2 | 17.8 | 18.4 | 44 | 11.07 | 84 |

| 50 | 2 | 19.0 | 19.2 | 52 | 12.09 | 102 |

| 65 | 2–1/2 | 23.6 | 28.9 | 64 | 15.29 | 121 |

| 80 | 3 | 25.9 | 30.5 | 79 | 16.64 | 146 |

| 100 | 4 | 27.7 | 33.0 | 79 | 18.67 | 152 |

(*) Dimension B is the minimum length of the perfect thread. The length of useful thread (B plus threads with fully formed roots and get crests) shall not be less than L2 (effective length of external thread) required by American National Standard for pipe threads (ANSI / ASME B1.20.1).

ASME B16.11 90 Degree Elbow Dimensions

Dimensions in Millimeters

| Socket Welding | ||||||||

| DN | Nom. Pipe Size |

B(Min) | C | D(Avg) |

A | G (Min) |

J (Min) |

|

| (Avg) | (Min) | |||||||

3000Lb

| 6 | 1/8 | 10.8 | 3.18 | 3.18 | 6.9 | 11.0 | 2.41 | 9.5 |

| 8 | 1/4 | 14.2 | 3.78 | 3.30 | 9.3 | 11.0 | 3.02 | 9.5 |

| 10 | 3/8 | 17.6 | 4.01 | 3.50 | 12.6 | 13.5 | 3.20 | 9.5 |

| 15 | 1/2 | 21.8 | 4.67 | 4.09 | 15.8 | 15.5 | 3.73 | 9.5 |

| 20 | 3/4 | 27.2 | 4.90 | 4.27 | 21.0 | 19.0 | 3.91 | 12.5 |

| 25 | 1 | 33.9 | 5.69 | 4.96 | 26.07 | 22.5 | 4.55 | 12.5 |

| 32 | 1–1/4 | 42.7 | 6.07 | 5.28 | 35.1 | 27.0 | 4.85 | 12.5 |

| 40 | 1–1.2 | 48.8 | 6.35 | 5.54 | 40.9 | 32.0 | 5.08 | 12.5 |

| 50 | 2 | 61.2 | 6.93 | 6.04 | 52.5 | 38.0 | 5.54 | 16.0 |

| 65 | 2-1/2 | 73.9 | 8.76 | 7.67 | 62.7 | 41.0 | 7.01 | 16.0 |

| 80 | 3 | 89.8 | 9.52 | 8.30 | 78.0 | 57.0 | 7.62 | 16.0 |

| 100 | 4 | 115.2 | 10.69 | 9.35 | 102.3 | 66.5 | 8.56 | 19.0 |

6000Lb

| 6 | 1/8 | 10.8 | 3.96 | 3.43 | 4.0 | 11.0 | 3.15 | 9.5 |

| 8 | 1/4 | 14.2 | 4.60 | 4.01 | 6.4 | 13.5 | 3.68 | 9.5 |

| 10 | 3/8 | 17.6 | 5.03 | 4.37 | 9.2 | 15.5 | 4.01 | 9.5 |

| 15 | 1/2 | 21.8 | 5.97 | 5.18 | 11.8 | 19.0 | 4.78 | 9.5 |

| 20 | 3/4 | 27.2 | 6.96 | 6.04 | 15.6 | 22.5 | 5.56 | 12.5 |

| 25 | 1 | 33.9 | 7.92 | 6.93 | 20.7 | 27.0 | 6.35 | 12.5 |

| 32 | 1-1/4 | 42.7 | 7.92 | 6.93 | 29.5 | 32.0 | 6.35 | 12.5 |

| 40 | 1-1/2 | 48.8 | 8.92 | 7.80 | 34.0 | 38.0 | 7.14 | 12.5 |

| 50 | 2 | 61.2 | 10.92 | 9.50 | 42.9 | 41.0 | 8.74 | 16.0 |

9000Lb

| 15 | 1/2 | 21.8 | 9.35 | 8.18 | 6.4 | 25.5 | 7.47 | 9.5 |

| 20 | 3/4 | 27.2 | 9.78 | 8.56 | 11.1 | 28.5 | 7.82 | 12.5 |

| 25 | 1 | 33.9 | 11.38 | 9.96 | 15.2 | 32.0 | 9.09 | 12.5 |

| 32 | 1-1/4 | 42.7 | 12.14 | 10.62 | 22.8 | 35.0 | 9.70 | 12.5 |

| 40 | 1-1/2 | 48.8 | 12.70 | 11.12 | 28.0 | 38.0 | 10.15 | 12.5 |

| 50 | 2 | 61.2 | 13.84 | 12.12 | 38.2 | 54.0 | 11.07 | 16.0 |

(1) Average socket Wall Thickness around the periphery shall be no less than the listed values. The minimum values are permitted in localized areas.

Dimensions in Millimeters.

| Threaded | ||||||

| DN | Nom. Pipe Size | Length of Thread. (Min) |

A | G (Min) |

H | |

| B(*) | L2(*) | |||||

2000Lb

| 6 | 1/8 | 6.4 | 6.7 | 21 | 3.18 | 22 |

| 8 | 1/4 | 8.1 | 10.2 | 21 | 3.18 | 22 |

| 10 | 3/8 | 9.1 | 10.4 | 25 | 3.18 | 25 |

| 15 | 1/2 | 10.9 | 13.6 | 28.0 | 3.18 | 33 |

| 20 | 3/4 | 12.7 | 13.9 | 33 | 3.18 | 38 |

| 25 | 1 | 14.7 | 17.3 | 38 | 3.68 | 46 |

| 32 | 1-1/4 | 17.0 | 18.0 | 44 | 3.89 | 56 |

| 40 | 1–1/2 | 17.8 | 18.4 | 51 | 4.01 | 62 |

| 50 | 2 | 19.0 | 19.2 | 60 | 4.27 | 75 |

| 55 | 2-1/2 | 23.6 | 28.9 | 76 | 5.61 | 92 |

| 80 | 3 | 25.9 | 30.5 | 86 | 5.99 | 109 |

| 100 | 4 | 27.7 | 33.0 | 106 | 6.55 | 146 |

3000Lb

| 6 | 1/8 | 6.4 | 6.7 | 21 | 3.18 | 22 |

| 8 | 1/4 | 8.1 | 10.2 | 25 | 3.30 | 25 |

| 10 | 3/8 | 9.1 | 9.1 | 28 | 3.51 | 33 |

| 15 | 1/2 | 10.9 | 13.6 | 33 | 4.09 | 38 |

| 20 | 3/4 | 12.7 | 13.9 | 38 | 4.32 | 46 |

| 25 | 1 | 14.7 | 17.3 | 44 | 4.98 | 56 |

| 32 | 1-1/4 | 17.0 | 18.0 | 51 | 5.28 | 62 |

| 40 | 1-1/2 | 17.8 | 18.4 | 60 | 5.56 | 75 |

| 50 | 2 | 19.0 | 19.2 | 64 | 7.14 | 84 |

| 65 | 2-1/2 | 23.6 | 28.9 | 83 | 7.65 | 102 |

| 80 | 3 | 25.9 | 30.5 | 95 | 8.84 | 121 |

| 100 | 4 | 27.7 | 33.0 | 114 | 11.18 | 152 |

6000Lb

| 6 | 1/8 | 6.4 | 6.7 | 25 | 6.35 | 25 |

| 8 | 1/4 | 8.1 | 10.2 | 28 | 6.60 | 33 |

| 10 | 3/8 | 9.1 | 10.4 | 33 | 6.98 | 38 |

| 15 | 1/2 | 10.9 | 13.6 | 38 | 8.15 | 46 |

| 20 | 3/4 | 12.7 | 13.9 | 44 | 8.53 | 56 |

| 25 | 1 | 14.7 | 17.3 | 51 | 9.93 | 62 |

| 32 | 1-1/4 | 17.0 | 18.0 | 60 | 10.59 | 75 |

| 40 | 1-1/2 | 17.8 | 18.4 | 64 | 11.07 | 84 |

| 50 | 2 | 19.0 | 19.2 | 83 | 12.09 | 102 |

| 65 | 2-1/2 | 23.6 | 28.9 | 95 | 15.29 | 121 |

| 80 | 3 | 25.9 | 30.5 | 106 | 16.64 | 146 |

| 100 | 4 | 27.7 | 33.0 | 114 | 18.67 | 152 |

Dimension B is the minimum length of a perfect thread. The length of useful thread (B plus threads with fully formed roots and flat crests) shall not be less than L2 (effective length of external thread) required by American National Standard for pipe threads (ANSI I ASME B1.20.1).

ASME B16.11 Bushing Dimensions

Dimensions in Millimeters

| Hex Head Plug | ||||

| DN | Nom. Pipe Size |

A (Min) |

F (Nom) |

H (Min) |

| 6 | 1/8 | 10 | 11.11 | 6 |

| 8 | 1/4 | 11 | 15.88 | 6 |

| 10 | 3/8 | 13 | 17.46 | 8 |

| 15 | 1/2 | 14 | 22.23 | 8 |

| 20 | 3/4 | 16 | 26.99 | 10 |

| 25 | 1 | 19 | 34.93 | 10 |

| 32 | 1-1/4 | 21 | 44.45 | 14 |

| 40 | 1-1/2 | 21 | 50.80 | 16 |

| 50 | 2 | 22 | 63.50 | 18 |

| 65 | 2-1/2 | 27 | 76.20 | 19 |

| 😯 | 3 | 28 | 88.90 | 21 |

| 100 | 4 | 32 | 117.48 | 25 |

Dimensions in Millimeters.

| Hex Head gushing | ||||

| DN | Nom. Pipe Size |

A (Min) |

F (Non) |

G (Min) |

| 8 | 1/4 | 11 | 15.88 | 3 |

| 10 | 3/8 | 13 | 17.46 | 4 |

| 15 | 1/2 | 14 | 22.23 | 5 |

| 20 | 3/4 | 16 | 26.99 | 6 |

| 25 | 1 | 19 | 34.93 | 6 |

| 32 | 1-1/4 | 21 | 44.45 | 7 |

| 40 | 1-1/2 | 21 | 50.80 | 8 |

| 50 | 2 | 22 | 63.50 | 9 |

| 65 | 2-1/2 | 27 | 76.20 | 10 |

| 80 | 3 | 28 | 88.90 | 10 |

| 100 | 4 | 32 | 117.48 | 13 |

CAUTIONARY NOTE REGARDING HEX BUSHINGS.

Hex Head Bushings of one-size reduction should not be used in services where they might be subject to harmful loads and forces than internal’ pressures.

ASME B16.11 Cap Dimensions

Dimensions in Millimeters.

| Socket Welding | ||||||

| DN | Nom Pipe Size |

B (Min) |

C | K (Min) |

J (Min) |

|

| (Avg) | (Min) | |||||

3000Lb

| 6 | 1/8 | 10.8 | 3.18 | 3.18 | 4.8 | 9.5 |

| 8 | 1/4 | 14.2 | 17.8 | 3.30 | 4.8 | 9.5 |

| 10 | 3/8 | 17.6 | 4.01 | 3.50 | 4.8 | 9.5 |

| 15 | 1/2 | 21.8 | 4.67 | 4.09 | 6.4 | 9.5 |

| 20 | 3/4 | 27.2 | 4.90 | 4.27 | 6.4 | 12.5 |

| 25 | 1 | 33.9 | 5.69 | 4.98 | 9.6 | 12.5 |

| 32 | 1–1/4 | 42.7 | 6.07 | 5.28 | 9.6 | 12.5 |

| 40 | 1-1/2 | 48.8 | 6.35 | 5.54 | 11.2 | 12.5 |

| 50 | 2 | 61.2 | 6.93 | 6.04 | 12.7 | 16.0 |

| 65 | 2-1/2 | 73.9 | 8.76 | 7.67 | 15.7 | 16.0 |

| 😯 | 3 | 89.8 | 9.52 | 8.30 | 19.0 | 16.0 |

| 100 | 4 | 115.2 | 10.69 | 9.35 | 22.4 | 19.0 |

6000Lb

| 6 | 1/8 | 10.8 | 3.96 | 3.43 | 6.4 | 9.5 |

| 8 | 1/4 | 14.2 | 4.60 | 4.01 | 6.4 | 9.5 |

| 10 | 3/8 | 17.6 | 5.03 | 4.37 | 6.4 | 9.5 |

| 15 | 1/2 | 21.8 | 5.97 | 5.18 | 7.9 | 9.5 |

| 20 | 3/4 | 27.2 | 6.96 | 6.04 | 7.9 | 12.5 |

| 25 | 1 | 33.9 | 7.92 | 6.93 | 11.2 | 12.5 |

| 32 | 1-1/4 | 42.7 | 7.92 | 6.93 | 11.2 | 12.5 |

| 40 | 1-1/2 | 48.8 | 8.92 | 7.80 | 12.7 | 12.5 |

| 50 | 2 | 61.2 | 10.92 | 9.50 | 15.7 | 16.0 |

9000Lb

| 15 | 1/2 | 21.8 | 9.35 | 8.18 | 11.2 | 9.5 |

| 20 | 3/4 | 27.2 | 9.78 | 8.56 | 12.7 | 12.5 |

| 25 | 1 | 33.9 | 11.38 | 9.96 | 14.2 | 12.5 |

| 32 | 1–1/4 | 42.7 | 12.14 | 10.62 | 14.2 | 12.5 |

| 40 | 1-1/2 | 48.8 | 12.70 | 11.12 | 15.7 | 12.5 |

| 50 | 2 | 61.2 | 13.84 | 12.21 | 19.0 | 16.0 |

(1) Average socket Wail Thickness around the periphery shall be no less than the listed values. The minimum values are permitted in localized areas.

Dimensions are in Millimeters.

| Threaded | |||||

| Nom | Length of Thread. | ||||

| DN | Pipe | (Min) | P | D | G |

| Size | B | L2 | (Min) | |||

3000Lb

| 6 | 1/8 | 6.4 | 6.7 | 19 | 16 | 4.8 |

| 8 | 1/4 | 8.1 | 10.2 | 25 | 19 | 4.8 |

| 10 | 3/8 | 9.1 | 10.4 | 25 | 22 | 4.8 |

| 15 | 1/2 | 10.9 | 13.6 | 32 | 28 | 6.4 |

| 20 | 3/4 | 12.7 | 13.9 | 37 | 35 | 6.4 |

| 25 | 1 | 14.7 | 17.3 | 41 | 44 | 9.7 |

| 32 | 1-1/4 | 17.0 | 18.4 | 44 | 57 | 9.7 |

| 40 | 1–1/2 | 17.8 | 18.4 | 44 | 64 | 11.2 |

| 50 | 2 | 19.0 | 19.2 | 48 | 76 | 12.7 |

| 65 | 2-1/2 | 23.6 | 28.9 | 60 | 92 | 15.7 |

| 80 | 3 | 25.9 | 30.5 | 65 | 108 | 19.0 |

| 100 | 4 | 27.7 | 33.0 | 68 | 140 | 22.4 |

6000Lb

| 8 | 1/4 | 8.1 | 10.2 | 27 | 25 | 6.4 |

| 10 | 3/8 | 9.1 | 10.4 | 27 | 32 | 6.4 |

| 15 | 1/2 | 10.9 | 13.6 | 33 | 38 | 7.9 |

| 20 | 3/4 | 12.7 | 13.9 | 38 | 44 | 7.9 |

| 25 | 1 | 14.7 | 17.3 | 43 | 57 | 11.2 |

| 32 | 1-1/4 | 17.0 | 18.4 | 46 | 64 | 11.2 |

| 40 | 1-1/2 | 17.8 | 18.4 | 48 | 76 | 12.7 |

| 50 | 2 | 19.0 | 19.2 | 51 | 92 | 15.7 |

| 65 | 2-1/2 | 23.6 | 28.9 | 64 | 108 | 19.0 |

| 80 | 3 | 25.9 | 30.5 | 68 | 127 | 22.4 |

| 100 | 4 | 27.7 | 33.0 | 75 | 159 | 28.4 |

Dimension B is the minimum length of the perfect thread. The length of useful thread (B plus threads with fully formed roots and flat crests) shall not be less than L2 (effective length of external thread) required by the American National Standard for pipe threads (ANSI ASME B1.20.1).

ASME B16.11 Cross Dimensions

Dimensions in Millimeters.

| Socket Welding | ||||||

| Nom , DN Pipe Size |

B(2) | C(1) | D(2) | A(2) | J (Min) |

|

| (Avg) | (Min) | |||||

3000Lb

| 6 | 1/8 | 10.8 | 3.18 | 3.18 | 6.9 | 11.0 | 9.5 |

| 8 | 1/4 | 14.2 | 3.78 | 3.30 | 9.3 | 11.0 | 9.5 |

| 10 | 3/8 | 17.6 | 4.01 | 3.50 | 12.6 | 13.5 | 9.5 |

| 15 | 1/2 | 21.8 | 4.67 | 4.09 | 15.8 | 15.5 | 9.5 |

| 20 | 3/4 | 27.2 | 4.90 | 4.27 | 21.0 | 19.0 | 12.5 |

| 25 | 1 | 33.9 | 5.69 | 4.98 | 26.7 | 22.5 | 12.5 |

| 32 | 1-1/4 | 42.7 | 6.07 | 5.28 | 35.1 | 27.0 | 12.5 |

| 40 | 1-1/2 | 48.8 | 6.35 | 5.54 | 40.9 | 32.0 | 12.5 |

| 50 | 2 | 61.2 | 6.93 | 6.04 | 52.5 | 38.0 | 16.0 |

| 65 | 2-1/2 | 73.9 | 8. 76 | 7.67 | 62.7 | 41.0 | 16.0 |

| 80 | 3 | 89.8 | 9.52 | 8.30 | 78.0 | 57.0 | 16.0 |

| 100 | 4 | 115.2 | 10.69 | 9.35 | 102.3 | 66.5 | 19.0 |

6000Lb

| 16 | 1/8 | 10.8 | 3.96 | 3.43 | 4.0 | 11.0 | 9 .5 |

| 8 | 1/4 | 14.2 | 4.60 | 4.01 | 6.4 | 13.6 | 9.5 |

| 10 | 3/8 | 17.6 | 5.03 | 4.37 | 9.2 | 15.5 | 9.5 |

| 15 | 1/2 | 21.8 | 5.97 | 5.18 | 11.8 | 19.0 | 9.5 |

| 20 | 3/4 | 27.2 | 6.96 | 6.04 | 15.6 | 22.5 | 12.5 |

| 25 | 1 | 33.9 | 7.92 | 6.93 | 20.7 | 27.0 | 12.5 |

| 32 | 1-1/4 | 42.7 | 7.92 | 6.93 | 29.5 | 32.0 | 12.5 |

| 40 | 1-1/2 | 48.8 | 8.92 | 7.80 | 34.0 | 38.0 | 12.5 |

| 50 | 2 | 61.2 | 10.92 | 9.50 | 42.9 | 41.0 | 16.0 |

9000Lb

| 15 | 1/2 | 21.8 | 9.35 | 8.18 | 6.4 | 25.5 | 9.5 |

| 20 | 3/4 | 27.2 | 9.78 | 8.56 | 11.1 | 28.5 | 12.5 |

| 25 | 1 | 33.9 | 11.38 | 9.96 | 15.2 | 32.0 | 12.5 |

| 32 | 1–1/4 | 42.7 | 12.14 | 10.62 | 22.8 | 35.0 | 12.5 |

| 40 | 1-1/2 | 48.8 | 12.70 | 11.12 | 28.0 | 38.0 | 12.5 |

| 50 | 2 | 61.2 | 13.84 | 12.12 | 38.2 | 54.0 | 16.0 |

(1) Average socket Wall Thickness around the periphery shall be no less than the listed values. The minimum values are permitted in localized areas.

Dimensions in Millimeters.

| Threaded | |||||

| DN | Nom Pipe Size |

Length of Thread. ( min) |

A | H | |

| B(*) | L2(*) | ||||

2000Lb

| 6 | 1/8 | 6.4 | 6.7 | 21 | 22 |

| 8 | 1/4 | 8.1 | 10.2 | 21 | 22 |

| 10 | 3/8 | 9.1 | 10.4 | 25 | 25 |

| 15 | 1/2 | 10.9 | 13.6 | 28 | 33 |

| 20 | 3/4 | 12.7 | 13.9 | 33 | 38 |

| 25 | 1 | 14.7 | 17.3 | 38 | 46 |

| 32 | 1-1/4 | 17.0 | 18.0 | 44 | 56 |

| 40 | 1-1/2 | 17.8 | 18.4 | 51 | 62 |

| 50 | 2 | 19.0 | 19.2 | 60 | 75 |

| 65 | 2-1/2 | 23.6 | 28.9 | 76 | 92 |

| 80 | 3 | 25.9 | 30.5 | 86 | 109 |

| 100 | 4 | 27.7 | 33.0 | 106 | 146 |

3000Lb

| 6 | 1/8 | 6.4 | 6.7 | 21 | 22 |

| 8 | 1/4 | 8.1 | 10.2 | 25 | 25 |

| 10 | 3/8 | 9.1 | 10.4 | 28 | 33 |

| 15 | 1/2 | 10.9 | 13.6 | 33 | 38 |

| 20 | 3/4 | 12.7 | 13.9 | 38 | 46 |

| 25 | 1 | 14.7 | 17.3 | 44 | 56 |

| 32 | 1-1/4 | 17.0 | 18.0 | 51 | 62 |

| 40 | 1-1/2 | 17.8 | 18.4 | 60 | 75 |

| 50 | 2 | 19.0 | 19.2 | 64 | 84 |

| 65 | 2-1/2 | 23.6 | 28.9 | 83 | 102 |

| 80 | 3 | 25.9 | 30.5 | 95 | 121 |

| 100 | 4 | 27.7 | 33.0 | 114 | 152 |

6000Lb

| 6 | 1/8 | 6.4 | – | 6.7 | – | 25 | 25 |

| 8 | 1/4 | 8.1 | – | 10.2 | – | 28 | 33 |

| 10 | 3/8 | 9.1 | – | 10.4 | – | 33 | 38 |

| 15 | 1/2 | 10.9 | – | 13.6 | – | 38 | 46 |

| 20 | 3/4 | 12.7 | – | 13.9 | – | 44 | 56 |

| 25 | 1 | 14.7 | – | 17.3 | – | 51 | 52 |

| 32 | 1-1/4 | 17.0 | – | 18.0 | – | 60 | 75 |

| 40 | 1-1/2 | 17.8 | – | 18.4 | – | 64 | 84 |

| 50 | 2 | 19.0 | – | 19.2 | – | 83 | 102 |

| 65 | 2–1/2 | 23.6 | – | 28.9 | – | 95 | 121 |

| 80 | 3 | 25.9 | – | 30.5 | – | 106 | 146 |

| 100 | 4 | 27.7 | – | 33.0 | – | 114 | 152 |

Dimension B is the minimum length of the perfect thread. the length of useful thread (B plus threads with fully formed roots and flat crests) shall not be less than L2 (effective length of external thread) required by American National Standard for pipe threads (ANSI ASME B1.20.1)

ASME B16.11 Full Coupling Dimensions

Dimensions in Millimeters.

| Socket Welding | |||||||

| DN | Nom Pipe Size |

B(2) | C(1) | D(2) | E(2) | j (Min) |

|

| (Avg) | (Min) | ||||||

3000Lb

| 6 | 1/8 | 10.8 | 3.18 | 3.18 | 6.9 | 6.5 | 9.5 |

| 8 | 1/4 | 14.2 | 3.78 | 3.30 | 9.3 | 6.5 | 9.5 |

| 10 | 3/8 | 17.6 | 4.01 | 15.0 | 12.6 | 6.5 | 9.5 |

| 15 | 1/2 | 21.8 | 4.67 | 4.09 | 15.6 | 9.5 | 9.5 |

| 20 | 3/4 | 27.2 | 4.90 | 42.7 | 21.0 | 9.5 | 125 |

| 25 | 1 | 33.9 | 5.69 | 4.98 | 26.7 | 12.5 | 12.5 |

| 32 | 1-1/4 | 42.7 | 6.07 | 5.28 | 35.1 | 12.5 | 12.5 |

| 40 | 1–1/2 | 46.8 | 6.35 | 5.54 | 40.9 | 12.5 | 12.5 |

| 50 | 2 | 61.2 | 6.93 | 6.04 | 52.5 | 19.0 | 16.0 |

| 65 | 2-1/2 | 73.9 | 8.76 | 7.67 | 62.7 | 19.0 | 16.0 |

| 80 | 3 | 89.8 | 9.52 | 8.30 | 78.0 | 19.0 | 16.0 |

| 100 | 4 | 115.2 | 10.69 | 9.35 | 102.3 | 19.0 | 19.0 |

6000Lb

| 6 | 1/8 | 10.8 | 3.96 | 3.43 | 4.0 | 6.5 | 9.5 |

| 8 | 1/4 | 14.2 | 4.60 | 401 | 6.4 | 6.5 | 9.5 |

| 10 | 3/8 | 17.6 | 5.03 | 4.37 | 9.2 | 6.5 | 9.5 |

| 15 | 1/2 | 21.8 | 5.97 | 5.18 | 11.8 | 9.5 | 9.5 |

| 20 | 3/4 | 27.2 | 6.96 | 6.04 | 15.6 | 9.5 | 12.5 |

| 25 | 1 | 31.9 | 7.92 | 6.93 | 20.7 | 12.5 | 12.5 |

| 32 | 1-1/4 | 42.7 | 7.92 | 6.93 | 29.5 | 12.5 | 12.5 |

| 40 | 1-1/2 | 46.8 | 6.92 | 17.80 | 34.0 | 12.5 | 12.5 |

| 50 | 2 | 61.2 | 10.92 | 9.50 | 42.9 | 19.0 | 16.0 |

9000Lb

| 15 | 1/2 | 21.6 | 9.35 | 8.15 | 6.4 | 9.5 | 9.5 |

| 20 | 3/4 | 27.2 | 9.78 | 8.56 | 11.1 | 9.5 | 12.5 |

| 25 | 1 | 33.9 | 11.38 | 9.96 | 15.2 | 12.5 | 12.5 |

| 32 | 1-1/4 | 42.7 | 12.14 | 10.62 | 22.8 | 12.5 | 12.5 |

| 40 | 1-1/2 | 48.8 | 12.70 | 11.12 | 28.0 | 12.5 | 12.5 |

| 50 | 2 | 61.2 | 13.84 | 12.12 | 38.2 | 19.0 | 16.0 |

(1) Average socket Wall Thickness around the periphery shall be no less than the listed values. The minimum values are permitted in localized areas.

(2) Reducer “C. J. E” in accordance with large size. “D” in accordance with small size. The others are in accordance with each size.

Dimensions Millimeters.

| Threaded | |||||

| DN | Nom. Pipe Size |

Length of Thread. (Min) |

w | D | |

| B(*) | L2(*) | ||||

3000Lb

| 6 | 1/8 | 6.4 | 6.7 | 32 | 16 |

| 8 | 1/4 | 8.1 | 10.2 | 35 | 19 |

| 10 | 3/8 | 9.1 | 10.4 | 38 | 22 |

| 15 | 1/2 | 10.9 | 13.6 | 48 | 28 |

| 20 | 3/4 | 12.7 | 13.9 | 51 | 35 |

| 25 | 1 | 14.7 | 17.3 | 60 | 44 |

| 32 | 1-1/4 | 17.0 | 18.4 | 67 | 57 |

| 40 | 1-1/2 | 17.8 | 18.4 | 79 | 64 |

| 50 | 2 | 19.0 | 19.2 | 86 | 76 |

| 65 | 2-1/2 | 23.6 | 28.9 | 92 | 92 |

| 80 | 3 | 25.9 | 30.5 | 108 | 108 |

| 100 | 4 | 27.7 | 33.0 | 121 | 140 |

6000Lb

| 6 | 1/8 | 6.4 | 6.7 | 32 | 22 |

| 8 | 1/4 | 8.1 | 10.2 | 35 | 25 |

| 10 | 3/8 | 9.1 | 10.4 | 38 | 32 |

| 15 | 1/2 | 10.9 | 13.6 | 48 | 38 |

| 20 | 3/4 | 12.7 | 13.9 | 51 | 44 |

| 25 | 1 | 14.7 | 17.3 | 60 | 57 |

| 32 | 1-1/4 | 17.0 | 18.4 | 67 | 64 |

| 40 | 1-1/2 | 17.8 | 18.4 | 79 | 76 |

| 50 | 2 | 19.0 | 19.2 | 86 | 92 |

| 65 | 2-1/2 | 23.6 | 28.9 | 92 | 108 |

| 80 | 3 | 25.9 | 30.5 | 108 | 127 |

| 100 | 4 | 27.7 | 33.0 | 121 | 159 |

Dimension B is the minimum length of the perfect Thread. The length of useful thread (B plus threads- with fully formed roots and flat crests) shall not be less than L2 (effective length of external thread) required by American National Standard for pipe threads (ANSI ASME B1_20.1)

ASME B16.11 Half Coupling Dimensions

Dimensions in millimeters

| Socket Welding | |||||||

| DN | Nom. Pipe Size |

B(2) | C(1) | D | F | j (Min) |

|

| (Avg) | (Min) | ||||||

3000Lb

| 6 | 1/8 | 10.8 | 3.18 | 3.18 | 6.9 | 16.0 | 9.5 |

| 8 | 1/4 | 14.2 | 3.78 | 3.30 | 9.3 | 16.0 | 9.5 |

| 10 | 3/8 | 17.6 | 4.01 | 3.50 | 12.6 | 17.5 | 9.5 |

| 15 | 1/2 | 21.8 | 4.67 | 4.09 | 15.8 | 22.5 | 9.5 |

| 20 | 3/4 | 27.2 | 4.90 | 4.27 | 21.0 | 24.0 | 12.5 |

| 25 | 1 | 33.9 | 5.69 | 4.98 | 26.7 | 28.5 | 12.5 |

| 32 | 1–1/4 | 42.7 | 6.07 | 5.28 | 35.1 | 30.0 | 12.5 |

| 40 | 1–1/2 | 48.8 | 6.35 | 5.54 | 40.9 | 32.0 | 12.5 |

| 50 | 2 | 61.2 | 6.93 | 6.04 | 52.5 | 41.0 | 16.0 |

| 65 | 2-1/2 | 73.9 | 8. 76 | 7.67 | 62.7 | 43.0 | 16.0 |

| 80 | 3 | 89.8 | 9.52 | 8.30 | 77.9 | 44.5 | 16.0 |

| 100 | 4 | 115.2 | 10.69 | 9.35 | 102.3 | 48.0 | 19.0 |

6000Lb

| 6 | 1/8 | 10.8 | 3.96 | 3.43 | 4.0 | 16.0 | 9.5 |

| 8 | 1/4 | 14.2 | 4.60 | 4.01 | 6.4 | 16.0 | 9.5 |

| 10 | 3/8 | 17.6 | 5.03 | 4.37 | 9.2 | 17.5 | 9.5 |

| 15 | 1/2 | 21.8 | 5.97 | 5.18 | 11.8 | 22.5 | 9.5 |

| 20 | 3/4 | 27.2 | 6.96 | 6.04 | 15.6 | 24.0 | 12.5 |

| 25 | 1 | 33.9 | 7.92 | 6.93 | 20.7 | 28.5 | 12.5 |

| 32 | 1-1/4 | 42.7 | 7.92 | 6.93 | 29.5 | 30.0 | 12.5 |

| 40 | 1-1/2 | 48.8 | 8.92 | 7.80 | 34.0 | 32.0 | 12.5 |

| 50 | 2 | 61.2 | 10.92 | 9.50 | 42.9 | 41.0 | 16.0 |

9000Lb

| 15 | 1/2 | 21.8 | 9.35 | 8.18 | 6.4 | 22.5 | 9.5 |

| 20 | 3/4 | 27.2 | 9.78 | 8.56 | 11.1 | 24.0 | 12.5 |

| 25 | 1 | 33.9 | 11.38 | 9.96 | 15.2 | 28.5 | 12.5 |

| 32 | 1-1/4 | 42.7 | 12.14 | 10.62 | 22.8 | 30.0 | 12.5 |

| 40 | 1-1/2 | 48.8 | 12.70 | 11.12 | 28.0 | 32.0 | 12.5 |

| 50 | 2 | 61.2 | 13.84 | 12.12 | 38.2 | 41.0 | 16.0 |

Average socket Wall Thickness around the periphery shall be no less than the listed values. The minimum values are permitted in localized areas

Dimensions in millimeters.

| Threaded | |||||

| DN | Nom Pipe Size | Length of Thread. (Min) |

W | D | |

| B(*) | L2(*) | ||||

3000Lb

| 6 | 1/8 | 6.4 | 6.7 | 32 | 16 |

| 8 | 1/4 | 8.1 | 10.2 | 35 | 19 |

| 10 | 3/8 | 9.1 | 10.4 | 38 | 22 |

| 15 | 1/2 | 10.9 | 13.6 | 48 | 28 |

| 20 | 3/4 | 12.7 | 13.9 | 51 | 35 |

| 25 | 1 | 14.7 | 17.3 | 60 | 44 |

| 32 | 1-1/4 | 17.0 | 18.4 | 67 | 57 |

| 40 | 1-1/2 | 17.8 | 18.4 | 79 | 64 |

| 50 | 2 | 19.0 | 19.2 | 86 | 76 |

| 65 | 2-1/2 | 23.6 | 28.9 | 92 | 92 |

| 80 | 3 | 25.9 | 30.5 | 108 | 108 |

| 100 | 4 | 27.7 | 33.0 | 121 | 140 |

6000Lb

| 6 | 1/8 | 6.4 | 6.7 | 32 | 22 |

| 8 | 1/4 | 8.1 | 10.2 | 35 | 25 |

| 1 0 | 3/8 | 9.1 | 10.4 | 38 | 32 |

| 15 | 1/2 | 10.9 | 13.6 | 48 | 38 |

| 20 | 3/4 | 12.7 | 13.9 | 51 | 44 |

| 25 | 1 | 14.7 | 17.3 | 60 | 57 |

| 32 | 1-1/4 | 17.0 | 18.4 | 67 | 64 |

| 40 | 1-1/2 | 17.8 | 18.4 | 79 | 76 |

| 50 | 2 | 19.0 | 19.2 | 86 | 92 |

| 65 | 2-1/2 | 23.6 | 28.9 | 92 | 108 |

| 80 | 3 | 25.9 | 30.5 | 108 | 127 |

| 100 | 4 | 27.7 | 33.0 | 121 | 159 |

Dimension B is the minimum length of the perfect thread. The length of useful thread (B plus threads with fully formed root and, flat crests) shall not be less than L2 (effective length of external thread) required by American National Standard for pipe threads (ANSI I ASME B1.20.1).

ASME B16.11 Hex Head Plug Dimensions

Dimensions in Millimeters

| Hex Head Plug | ||||

| DN | Nom. Pipe Size |

A (Min) |

F (Nom) |

H (Min) |

| 6 | 1/8 | 10 | 11.11 | 6 |

| 8 | 1/4 | 11 | 15.88 | 6 |

| 10 | 3/8 | 13 | 17.46 | 8 |

| 15 | 1/2 | 14 | 22.23 | 8 |

| 20 | 3/4 | 16 | 26.99 | 10 |

| 25 | 1 | 19 | 34.93 | 10 |

| 32 | 1-1/4 | 21 | 44.45 | 14 |

| 40 | 1-1/2 | 21 | 50.80 | 16 |

| 50 | 2 | 22 | 63.50 | 18 |

| 65 | 2-1/2 | 27 | 76.20 | 19 |

| 😯 | 3 | 28 | 88.90 | 21 |

| 100 | 4 | 32 | 117.48 | 25 |

Dimensions in Millimeters.

| Hex Head gushing | ||||

| DN | Nom. Pipe Size |

A (Min) |

F (Non) |

G (Min) |

| 8 | 1/4 | 11 | 15.88 | 3 |

| 10 | 3/8 | 13 | 17.46 | 4 |

| 15 | 1/2 | 14 | 22.23 | 5 |

| 20 | 3/4 | 16 | 26.99 | 6 |

| 25 | 1 | 19 | 34.93 | 6 |

| 32 | 1-1/4 | 21 | 44.45 | 7 |

| 40 | 1-1/2 | 21 | 50.80 | 8 |

| 50 | 2 | 22 | 63.50 | 9 |

| 65 | 2-1/2 | 27 | 76.20 | 10 |

| 80 | 3 | 28 | 88.90 | 10 |

| 100 | 4 | 32 | 117.48 | 13 |

CAUTIONARY NOTE REGARDING HEX BUSHINGS.

Hex Head Bushings of one-size reduction should not be used in services where they might be subject to harmful loads and forces than internal’ pressures.

ASME B16.11 Round Head Plug Dimensions – Forged Fittings Dimensions

Dimensions in Millimeters.

| Square Head Plug | ||||

| DN | Nom. Pipe Size |

A (Min) |

B (Min) |

C (Min) |

| 6 | 1/8 | 10 | 6 | 7.15 |

| 8 | 1/4 | 11 | 6 | 9.55 |

| 10 | 3/8 | 13 | 8 | 11.11 |

| 15 | 1/2 | 14 | 10 | 14.29 |

| 20 | 3/4 | 16 | 11 | 15.88 |

| 25 | 1 | 19 | 13 | 20.64 |

| 32 | 1-1/4 | 21 | 14 | 23.81 |

| 40 | 1-1/2 | 21 | 16 | 28.58 |

| 50 | 2 | 22 | 18 | 33.27 |

| 65 | 2-1/2 | 27 | 19 | 38.10 |

| 80 | 3 | 28 | 21 | 42.86 |

| 100 | 4 | 32 | 25 | 63.50 |

Dimensions in Millimeters

| Round Head Plug | |||

| DN | Nom_ Pipe Size |

E (Nom) |

D (Min) |

| 6 | 1/8 | 10 | 35 |

| 8 | 1/4 | 14 | 41 |

| 10 | 3/8 | 18 | 41 |

| 15 | 1/2 | 21 | 44 |

| 20 | 3/4 | 27 | 44 |

| 25 | 1 | 33 | 51 |

| 32 | 1-1/4 | 43 | 51 |

| 40 | 1 -1/2 | 48 | 51 |

| 50 | 2 | 60 | 64 |

| 65 | 2-1/2 | 73 | 70 |

| 80 | 3 | 89 | 70 |

| 100 | 4 | 114 | 76 |

(1) ASME B16.11-2016 SIZE .2″ DATA “C”, WE CONVERT INCH DATA INTO MILLIMETERS.

ASME B16.11 Square Head Plug Dimensions

Dimensions in Millimeters.

| Square Head Plug | ||||

| DN | Nom. Pipe Size |

A (Min) |

B (Min) |

C (Min) |

| 6 | 1/8 | 10 | 6 | 7.15 |

| 8 | 1/4 | 11 | 6 | 9.55 |

| 10 | 3/8 | 13 | 8 | 11.11 |

| 15 | 1/2 | 14 | 10 | 14.29 |

| 20 | 3/4 | 16 | 11 | 15.88 |

| 25 | 1 | 19 | 13 | 20.64 |

| 32 | 1-1/4 | 21 | 14 | 23.81 |

| 40 | 1-1/2 | 21 | 16 | 28.58 |

| 50 | 2 | 22 | 18 | 33.27 |

| 65 | 2-1/2 | 27 | 19 | 38.10 |

| 80 | 3 | 28 | 21 | 42.86 |

| 100 | 4 | 32 | 25 | 63.50 |

Dimensions in Millimeters

| Round Head Plug | |||

| DN | Nom_ Pipe Size |

E (Nom) |

D (Min) |

| 6 | 1/8 | 10 | 35 |

| 8 | 1/4 | 14 | 41 |

| 10 | 3/8 | 18 | 41 |

| 15 | 1/2 | 21 | 44 |

| 20 | 3/4 | 27 | 44 |

| 25 | 1 | 33 | 51 |

| 32 | 1-1/4 | 43 | 51 |

| 40 | 1 -1/2 | 48 | 51 |

| 50 | 2 | 60 | 64 |

| 65 | 2-1/2 | 73 | 70 |

| 80 | 3 | 89 | 70 |

| 100 | 4 | 114 | 76 |

(1) ASME B16.11-2016 SIZE .2″ DATA “C”, WE CONVERT INCH DATA INTO MILLIMETERS.

ASME B16.11 90D Street Elbow Dimensions: Forged Fittings Dimensions

Dimensions in Millimeters.

| DN | Nom. Pipe Size |

H | A | J | G1 (Min) |

G2(1) (Min) |

B(2) (Min) |

L2 (2) (Min) |

L (MN) |

3000Lb

| 6 | 1/6 | 19 | 19 | 25 | 3.18 | 2.74 | 6.4 | 6.7 | 10.0 |

| 8 | 1/4 | 25 | 22 | 32 | 3.30 | 3.22 | 8.1 | 10.2 | 11.0 |

| 10 | 3/8 | 32 | 25 | 38 | 3.15 | 3.50 | 9.1 | 10.4 | 13.0 |

| 15 | 1/2 | 38 | 28 | 41 | 4.09 | 4.16 | 10.9 | 13.6 | 14.0 |

| 20 | 3/4 | 44 | 35 | 48 | 4.32 | 4.88 | 12.7 | 13.9 | 16.0 |

| 25 | 1 | 51 | 44 | 57 | 4.98 | 5.56 | 14.7 | 17.3 | 19 |

| 32 | 1-1/4 | 62 | 51 | 66 | 5.28 | 5.56 | 17.0 | 18.0 | 21.0 |

| 40 | 1-1/2 | 70 | 54 | 71 | 5.56 | 6.25 | 17.8 | 18.4 | 21.0 |

| 50 | 2 | 84 | 64 | 84 | 7.14 | 7.64 | 19.0 | 19.2 | 22.0 |

6000Lb

| 5 | 1/8 | 25 | 22 | 32 | 5.08 | 4.22 | 6.4 | 6.7 | 10.0 |

| 8 | 1/4 | 32 | 25 | 38 | 5.66 | 5.28 | 8.1 | 10.2 | 11.0 |

| 10 | 3/8 | 38 | 28 | 41 | 6.98 | 5.59 | 9.1 | 10.4 | 13.0 |

| 15 | 1/2 | 44 | 35 | 48 | 8.15 | 6.53 | 10.9 | 13.6 | 14.0 |

| 20 | 3/4 | 51 | 44 | 57 | 8.53 | 6.86 | 12.7 | 13.9 | 16.0 |

| 25 | 1 | 62 | 51 | 66 | 9.93 | 7.95 | 14.7 | 17.3 | 19.0 |

| 32 | 1-1/4 | 70 | 54 | 71 | 10.59 | 8.48 | 17.0 | 18.0 | 21.0 |

| 40 | 1-1/2 | 84 | 64 | 84 | 11.07 | 8.89 | 17.8 | 18.4 | 21.0 |

| 50 | 2 | 102 | 83 | 105 | 12.09 | 9.70 | 19.0 | 19.2 | 22.0 |

(1) Wall thickness before threading

(2)Dimension B is the minimum length of the perfect thread. The length of useful thread (B plus threads with fully formed roots and flat crests) shall not be less than L2 (effective length of external thread) required by American National Standard for pipe Threads (ANSI / ASME B1.20.1)

ASME B16.11 Tee Dimensions – Forged Fittings Dimensions

Forged Fittings Dimensions Dimensions in Millimeters.

| Socket Welding | |||||||

| DN | Nom. Pipe Size |

B(2) | c(1) (Avg) (Min) |

D(2) | A(2) | G (Min) |

J (Min) |

3000Lb

| 6 | 1/8 | 10.8 | 3.18 | 3.18 | 6.9 | 11.0 | 2.41 | 9.5 |

| 8 | 1/4 | 14.2 | 3.78 | 3.30 | 9.3 | 11.0 | 3.02 | 9.5 |

| 10 | 3/8 | 17.6 | 4.01 | 3.50 | 12.6 | 13.5 | 3.20 | 9.5 |

| 15 | 1/2 | 21.8 | 4.67 | 4.09 | 15.8 | 15.5 | 3.73 | 9.5 |

| 20 | 3/4 | 27.2 | 4.90 | 4.27 | 21.0 | 19.0 | 3.91 | 12.5 |

| 25 | 1 | 33.9 | 5.69 | 4.98 | 26.7 | 22.5 | 4.55 | 12.5 |

| 32 | 1-1/4 | 42.7 | 6.07 | 5.28 | 35.1 | 27.0 | 4.85 | 12.5 |

| 40 | 1-1/2 | 48.8 | 6.35 | 5.54 | 40.9 | 32.0 | 5.08 | 12.5 |

| 50 | 2 | 61.2 | 6.93 | 6.04 | 52.5 | 38.0 | 5.54 | 16.0 |

| 65 | 2-1/2 | 73.9 | 8.76 | 7.87 | 62.7 | 41.0 | 7.01 | 16.0 |

| 80 | 3 | 89.8 | 9.52 | 8.30 | 78.0 | 57.0 | 7.62 | 16.0 |

| 100 | 4 | 115.2 | 10.69 | 9.35 | 102.3 | 66.5 | 8.56 | 19.0 |

6000Lb

| 6 | 1/8 | 10.8 | 3.96 | 3.43 | 4.0 | 11.0 | 3.15 | 9.5 |

| 8 | 1/4 | 14.2 | 4.60 | 4.01 | 6.4 | 13.5 | 3.68 | 9.5 |

| 10 | 3/8 | 17.6 | 5.03 | 4.37 | 9.2 | 15.5 | 4.01 | 9.5 |

| 15 | 1/2 | 21.8 | 5.97 | 5.18 | 11.8 | 19.0 | 4.78 | 9.5 |

| 20 | 3/4 | 27.2 | 6.96 | 6.04 | 15.6 | 22.5 | 5.56 | 12.5 |

| 25 | 1 | 33.9 | 7.92 | 6.93 | 20.7 | 27.0 | 6.35 | 12.5 |

| 32 | 1-1/4 | 42.7 | 7.92 | 6.93 | 29.5 | 32.0 | 6.35 | 12.5 |

| 40 | 1-1/2 | 48.8 | 8.92 | 7.80 | 34.0 | 38.0 | 7.14 | 12.5 |

| 50 | 2 | 61.2 | 10.92 | 9.50 | 42.9 | 41.0 | 8.74 | 16.0 |

9000Lb

| 15 | 1/2 | 21.8 | 9.35 | 8.18 | 6.4 | 25.5 | 7.47 | 9.5 |

| 20 | 3/4 | 27.2 | 9.78 | 8.56 | 11.1 | 28.5 | 7.82 | 12.5 |

| 25 | 1 | 33.9 | 11.38 | 9.96 | 15.2 | 32.0 | 9.09 | 12.5 |

| 32 | 1-1/4 | 42.7 | 12.14 | 10.62 | 22.8 | 35.0 | 9.70 | 12.5 |

| 40 | 1-1/2 | 48.8 | 12.70 | 11.12 | 28.0 | 38.0 | 10.15 | 12.5 |

| 50 | 2 | 61.2 | 13.84 | 12.12 | 38.2 | 54.0 | 11.07 | 16 0 |

(1) Average socket wall Thickness around the periphery shall be no less than the listed values. The minimum values are permitted in localized areas

Dimensions in Millimeters.

| Threaded | ||||||

| DN | Norm Pipe Size |

Length of Thread. | A | G (Min) |

H | |

| B | L2 | |||||

2000Lb

| 6 | 1/8 | 6.4 | 6.7 | 21 | 3.18 | 22 |

| 8 | 1/4 | 8.1 | 10.2 | 21 | 3.18 | 22 |

| 10 | 3/8 | 9.1 | 10.4 | 25 | 3.18 | 25 |

| 15 | 1/2 | 10.9 | 13.6 | 28 | 3.18 | 33 |

| 20 | 3/4 | 12.7 | 13.9 | 33 | 3.18 | 38 |

| 25 | 1 | 14.7 | 17.3 | 38 | 3.68 | 46 |

| 32 | 1-1/4 | 17.0 | 18.0 | 44 | 3.89 | 56 |

| 40 | 1-1/2 | 17.8 | 18.4 | 51 | 4.01 | 62 |

| 50 | 2 | 19.0 | 19.2 | 60 | 4.27 | 75 |

| 65 | 2-1/2 | 23.6 | 28.9 | 76 | 5.61 | 92 |

| 80 | 3 | 25.9 | 30.5 | 86 | 5.99 | 109 |

| 100 | 4 | 27.7 | 33.0 | 106 | 6.55 | 146 |

3000Lb

| 5 | 1/8 | 6.4 | 6.7 | 21 | 3.18 | 22 |

| 8 | 1/4 | 8.1 | 10.2 | 25 | 3.30 | 25 |

| 10 | 3/8 | 9.1 | 10.4 | 28 | 3.51 | 33 |

| 15 | 1/2 | 10.9 | 13.6 | 33 | 4.09 | 38 |

| 20 | 3/4 | 12.7 | 13.9 | 38 | 4.32 | 46 |

| 25 | 1 | 14.7 | 17.3 | 44 | 4.98 | 56 |

| 32 | 1-1/4 | 17.0 | 18.0 | 51 | 5.28 | 62 |

| 40 | 1-1/2 | 17.8 | 18.4 | 60 | 5.56 | 75 |

| 50 | 2 | 19.0 | 19.2 | 64 | 7.14 | 84 |

| 65 | 2-1/2 | 23.6 | 28.9 | 83 | 7.65 | 102 |

| 80 | 3 | 25.9 | 30.5 | 95 | 8.84 | 121 |

| 100 | 4 | 27.7 | 33.0 | 114 | 11.18 | 152 |

6000Lb

| 6 | 1/8 | 6.4 | 6.7 | 25 | 6.35 | 25 |

| 8 | 1/4 | 8.1 | 10.2 | 28 | 6.60 | 33 |

| 10 | 3/8 | 9.1 | 10.4 | 33 | 6.98 | 38 |

| 15 | 1/2 | 10.9 | 13.6 | 38 | 8.15 | 46 |

| 20 | 3/4 | 12.7 | 13.9 | 44 | 8.53 | 56 |

| 25 | 1 | 14.7 | 17.3 | 51 | 9.93 | 62 |

| 32 | 1-1/4 | 17.0 | 18.0 | 60 | 10.59 | 75 |

| 40 | 1-1/2 | 17.8 | 18.4 | 64 | 11.07 | 84 |

| 50 | 2 | 19.0 | 19.2 | 83 | 12.09 | 102 |

| 65 | 2-1/2 | 23.6 | 28.9 | 95 | 15.29 | 121 |

| 80 | 3 | 25.9 | 30.5 | 106 | 16.64 | 146 |

| 100 | 4 | 27.7 | 33.0 | 114 | 18.67 | 152 |

Dimension B is the minimum length of the perfect thread. The length Of useful thread (B plus Threads with fully formed roots and flat crests) shall not be less than the L2 Reflective length of external thread)required by American National Standard for pipe threads (ANSI ASME B1.20.1).

Forged Fittings Types: Forged Fittings Dimensions