Inconel Flanged Tee Manufacturer, Monel Flanged Split Tee, Hastelloy Flanged Lateral Tee Suppliers

ISO Certified Suppliers and Exporters of Nickel 200 Flanged Tee, Inconel 600 Flanged Split Tee, Hastelloy c22 Industrial Flanged Tee, Inconel 601 Flanged Lateral Tee, Hastelloy c276 Flanged Hot Tap Split Tee Fitting, Inconel 625 Flanged Split Tee, Incoloy 825 Industrial Flanged Split Tee in India.

Largest stockists of Incoloy 925 Flanged Split Tee Pipe Fittings, Monel 400 Flanged Lateral Tee, Monel k500 Flanged Lateral Tee Pipe Fitting, Hastelloy B2 Reducing Lateral Tee, Hastelloy B3 Buttweld Reducing Lateral Tee, Inconel 718 Reducing Lateral Tee Pipe Fitting, Incoloy 925 Socket Weld Reducing Lateral Tee, Incoloy 800 Reducing Lateral Tee, Nickel 201 Flanged Split Tee, ASTM B336 Nickel Alloy 200 Flanged Lateral Tee, Nickel DIN 2.4066 Flanged Lateral Tee Pipe Fittings, Nickel Alloy UNS N02200 Flanged Tee.

Creative Piping Solutions is one of the leading Manufacturers, Suppliers, and Exporters of top quality High Nickel Alloy Flanged Split Tee in India. Hastelloy c22 Flanged Split Tee is Split Tee with a flange in its branch. Hastelloy c276 Split tee is comparable to regular tee according to ASME B16.9. But the most pipe of the split is cut within the middle. Inconel 600 Split tee is mainly used for decent tapping of the pipeline. Hot tapping is additionally called pressure tapping, which is the method of creating a connection to existing piping, or pressure vessels without the interrupting or emptying of that section of pipe. Inconel 601 Split tee is especially wont to repair the pipeline.

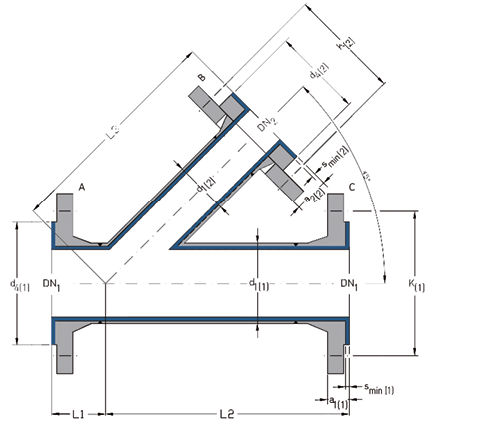

For the second Inconel 625 lateral pipe fittings, once the flow pipe direction is horizontal to the bottom, we will select the Alloy 400 Flanged Lateral Tee for higher support from the ground, and once the flow pipe direction is vertical, then we use the WYE Fitting. Alloy k500 Lateral pipe fittings have two types: Flanged Lateral Tee and latrolet (also referred to as Lateral Outlet). The Nickel 200 Flanged Lateral Tee’s form is a kind of pipe tee, the butt attachment Flanged Lateral Tees are made from steel pipes or forgings, the manufacturing normal is ASME B16.9.

Nickel 201 Flanged Lateral Tee is one quite Tee Pipe Fittings, that includes a forty-five-degree branch from a pipeline: (45° Flanged Lateral Tee). It’s a type of steel pipe tee, The branch direction is completely different from the straight tee. On the contrary to the High Nickel Alloy Flanged Lateral Tee, the straight tee encompasses a branch pipe direction of ninety degrees to the run pipe. The Nickel Alloy Flanged Lateral Tee divides Two branch pipes: one is that the same direction as the flow pipe.

High Nickel Alloy Flanged Tee Specifications

- Standards: ANSI B31.1, B31.3, ANSI B31.4 & B31.8

- Size: 2” TO 48”

- Pressure Ratings: 150# TO 2500#

- DIN: DIN2605, DIN2615, DIN2616, DIN2617, DIN28011

- EN: EN10253-1, EN10253-2

- Schedule: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

- Form: Lateral Tee, Split Tee, Reducing Lateral Tee

Inconel 600 Flanged Lateral Tee Dimensions

| Nominal Pipe Size |

Outside Diameter OD |

TYPE | X – S | STD | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| E & L | D | T | ID | E & L | D | T | ID | |||

| 1 1¼ 1½ |

1.315 1.660 1.900 |

B B B |

6.50 7.25 8.50 |

2.00 2.25 2.50 |

0.179 0.191 0.200 |

0.957 1.278 1.500 |

5.75 6.25 7.00 |

1.75 1.75 2.00 |

0.133 0.140 0.145 |

1.049 1.380 1.610 |

| 2 2½ 3 |

2.375 2.875 3.500 |

A/B B B |

*8.00 **9.00 10.50 11.00 |

2.50 2.50 3.00 |

0.128 0.276 0.300 |

1.939 2.323 2.900 |

8.00 9.50 10.00 |

2.50 2.50 3.00 |

0.154 0.203 0.216 |

2.067 2.469 3.068 |

| 3½ 4 5 |

4.000 4.500 5.562 |

B A/B B |

12.50 *12.00 **13.50 15.00 |

3.00 3.00 3.50 |

0.318 0.337 0.375 |

3.364 3.826 4.813 |

11.50 12.00 13.50 |

3.00 3.00 3.50 |

0.226 0.237 0.258 |

3.548 4.026 5.047 |

| 6 8 10 |

6.625 8.625 10.750 |

A/B B B |

*14.50 **17.50 20.50 24.00 |

*3.50 **4.00 5.00 5.50 |

0.432 0.500 0.500 |

5.761 7.625 9.750 |

14.50 17.50 20.50 |

3.50 4.50 5.00 |

0.280 0.322 0.365 |

6.065 7.981 10.020 |

| 12 14 16 |

12.750 14.000 16.000 |

B B B |

27.50 31.00 34.50 |

6.00 6.50 7.50 |

0.500 0.500 0.500 |

11.750 13.000 15.000 |

24.50 27.00 30.00 |

5.50 6.00 6.50 |

0.375 0.375 0.375 |

12.000 13.250 15.250 |

| 18 20 24 |

18.000 20.000 24.000 |

B B B |

37.50 40.50 47.50 |

8.00 8.50 10.00 |

0.500 0.500 0.500 |

17.000 19.000 23.000 |

32.00 35.00 40.50 |

7.00 8.00 9.00 |

0.375 0.375 0.375 |

17.250 19.250 23.250 |

Hastelloy Reducing Lateral Tee Manufacturing Standards

| ASME B16.25 | Buttwelding Ends |

|---|---|

| ASME B16.9 | Factory-Made Wrought Fittings Buttwelding |

| ASME Standard | ASME/ANSI B16.9, ASME/ANSI B16.28, MSS-SP-43 |

| DIN Standard | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| EN Standard | EN10253-2, EN10253-1 |

| ASME B16.28 | Wrought Steel Reducing Lateral Tees and Buttwelding Returns |

| MSS SP-43 | Wrought & Fabricated Butt-Welding Fitting for Low Pressure, Corrosion Resistant Applications |

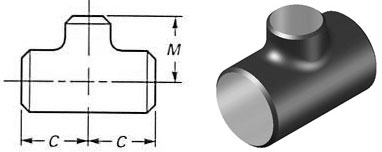

Nickel Alloy 200 Reducing Lateral Tee Dimensions

| Nominal Pipe Size | Outside diameter at bevel |

Center-to-End | |||

|---|---|---|---|---|---|

| Run | Outlet | Run | Outlet | Run (C) | Outlet (M) |

| 1/2″ | 1/4″ 3/8″ |

21.3 | 13.7 17.3 |

25 | 25 |

| 3/4″ | 3/8″ 1/2″ |

26.7 | 17.3 21.3 |

29 | 29 |

| 1″ | 1/2″ 3/4″ |

33.4 | 21.3 26.7 |

38 | 38 |

| 1 1/4″ | 1/2″ 3/4″ 1″ |

42.2 | 21.3 26.7 33.4 |

48 | 48 |

| 1 1/2″ | 1/2″ 3/4″ 1″ 1 1/4″ |

48.3 | 21.3 26.7 33.4 42.2 |

57 | 57 |

| 2″ | 3/4″ 1″ 1 1/4″ 1 1/2″ |

60.3 | 26.7 33.4 42.2 48.3 |

64 | 44 51 57 60 |

| 2 1/2″ | 1″ 1 1/4″ 1 1/2″ 2″ |

73.0 | 33.4 42.2 48.3 60.3 |

76 | 57 64 67 70 |

| 3″ | 1 1/4″ 1 1/2″ 2″ 2 1/2″ |

88.9 | 42.2 48.3 60.3 73.0 |

86 | 70 73 76 83 |

| 3 1/2″ | 1 1/2″ 2″ 2 1/2″ 3″ |

101.6 | 48.3 60.3 73.0 88.9 |

95 | 79 83 89 92 |

| 4″ | 1 1/2″ 2″ 2 1/2″ 3″ 3 1/2″ |

114.3 | 48.3 60.3 73.0 88.9 101.6 |

105 | 86 89 95 98 102 |

| 5″ | 2″ 2 1/2″ 3″ 3 1/2″ 4″ |

141.3 | 60.3 73.0 88.9 101.6 114.3 |

124 | 105 108 111 114 117 |

| 6″ | 2 1/2″ 3″ 3 1/2″ 4″ 5 |

168.3 | 73.0 88.9 101.6 114.3 141.3 |

143 | 121 124 127 130 137 |

| 8″ | 3 1/2″ 4″ 5″ 6″ |

219.1 | 101.6 114.3 141.3 168.3 |

178 | 152 156 162 168 |

| 10″ | 4″ 5″ 6″ 8″ |

273.0 | 114.3 141.3 168.3 219.1 |

216 | 184 191 194 203 |

| 12″ | 5″ 6″ 8″ 10″ |

323.8 | 141.3 168.3 219.1 273.0 |

254 | 216 219 229 241 |

| 14″ | 6″ 8″ 10″ 12″ |

355.6 | 168.3 219.1 273.0 323.8 |

279 | 238 248 257 |

| 16″ | 6″ 8″ 10″ 12″ 14″ |

406.4 | 168.3 219.1 273.0 323.8 355.6 |

305 | 264 273 283 295 305 |

| 18″ | 8″ 10″ 12″ 14″ 16″ |

457.0 | 219.1 273.0 323.8 355.6 406.4 |

343 | 298 308 321 330 330 |

| 20″ | 8″ 10″ 12″ 14″ 16″ 18″ |

508.0 | 219.1 273.0 323.8 355.6 406.4 457.0 |

381 | 324 333 346 356 356 368 |

| 22″ | 10″ 12″ 14″ 16″ 18″ 20″ |

559.0 | 273.0 323.8 355.6 406.4 457.0 508.0 |

419 | 359 371 381 381 394 406 |

| 24″ | 10″ 12″ 14″ 16″ 18″ 20″ 22″ |

610.0 | 273.0 323.8 355.6 406.4 457.0 508.0 559.0 |

432 | 384 397 406 406 419 432 432 |

Available grades of High Nickel Alloy Flanged Tee

- Nickel Alloy 200 Flanged Tee

- Nickel Alloy 201 Flanged Tee

- Inconel 600 Flanged Tee

- Inconel 601 Flanged Tee

- Inconel 625 Flanged Tee

- Inconel 718 Flanged Tee

- Incoloy 800 Flanged Tee

- Incoloy 825 Flanged Tee

- Incoloy 925 Flanged Tee

- Monel 400 Flanged Tee

- Monel k500 Flanged Tee

- Hastelloy C22 Flanged Tee

- Hastelloy C276 Flanged Tee

- Hastelloy b2 Flanged Tee

High Nickel Alloy Flanged Tee Application Industries

We produce full range of 600 Inconel Flanged Tee in every sizes, pressure / classes, dimensions to meet needs of customers. Our products are well accepted by the majority of customers. it’s widely used in aerospace, shipbuilding, metallurgy, automotive instrumentation, petrochemical, food machinery, biological engineering In the field of environmental protection.

- Refineries

- Food Processing & Dairy

- Oil and Gas Industry

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Power Generation

- Specialty Chemicals

- Sea Water Equipment

- Gas Processing

- Chemical Equipment

- Heat Exchangers

- Petrochemicals

- Pharmaceuticals

- Condensers

High Nickel Alloy Flanged Tee Inspection

We at Creative Piping Solutions ensures that all our materials go through strict quality tests before dispatching them to our clients. we conduct all necessary test of High Nickel Alloy Flanged Tee to assure the quality of deliver products to fit clients projects and needs. NDT test used for High Nickel Alloy Flanged Tee are Positive material identification (PMI), Penetrating liquids, Ferrite content, Hydrostatic test / hydro testing (pressure testing), Magnetic particles, Macrography, Micrography, Pneumatic pressure, Radiography. All of the listed test, the pressure testing is one of the most commonly specified, especially for mission critical fittings in the pipeline.

High Nickel Alloy Flanged Tee Packing & Forwarding

There are different ways of packing a Hastelloy c22 Flanged Tee, but two principles that are vital for any method to work prevent rusting and Sea transportation security. Our all products packed with seaworthy packing method then delivery to customers, usually the packing way include wooden box, wooden pallet. We make sure that it is seaworthy, strong, waterproof and easy for loading and unloading. All shipping and product details also stick to outside of package. Hastelloy c276 Flanged Tee pack with environmental poly bags, and then in free fumigation wooden cases or wooden plate. Hastelloy B2 Flanged Tee are packed in wooden corrugated boxes foiled in bubble wraps and plastic wraps.

High Nickel Alloy Flanged Tee Export & Supply to below mentioned Countries

ASIA: Malaysia, India, Taiwan, Cambodia, Singapore, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Myanmar.

SOUTH AMERICA: Venezuela, Argentina, Bolivia, Colombia, Ecuador, Guyana, Paraguay, Uruguay, Brazil, Chile.

AFRICA: South Africa, Nigeria, Algeria, Angola, Libya, Egypt, Gabon, Sudan, Equatorial Guinea, The Republic Of Congo.

NORTH AMERICA: USA, Canada, Mexico, Panama, Costa Rica, Puerto Rico, Trinidad And Tobago, Jamaica, Bahamas, Denmark.

EUROPE: UK, Netherlands, Russia, Norway, Germany, France, Italy, Spain, Ukraine, Belgium, Greece, Hungary, Albania, Austria, Finland, Ireland, Croatia, Slovenia, Malta, Switzerland, Slovakia, Czech Republic, Portugal.