Inconel Pipe Spool Manufacturer, Monel Pipe Spool, Hastelloy Pre-Fabricated Piping Spools Suppliers

ISO Certified Suppliers and Exporters of Nickel 200 Flanged Pipe Spool, Inconel 600 FBE Coated Pipe Spool, Hastelloy c22 Industrial Piping Spool, Inconel 601 Welded Fixed Flanged Pipe Spool, Hastelloy c276 Rotating Flanged Pipe Spool, Inconel 625 Fusion Bonded Epoxy (FBE) Coated Spool Pipe, Incoloy 825 Internal Fusion Bonded Epoxy (FBE) Coating Pipe Spool in India.

- High Nickel Alloy Pipe Spool Specifications

- Inconel 600 Pipe Spools Range

- Hastelloy Pipe Spool Dimensions, Size and Schedule

- Nickel Alloy 200 Flanged Pipe Spool Dimensions

- Available grades of High Nickel Alloy Pipe Spool

- Available grades of High Nickel Alloy Flanged Pipe Spool

- Available grades of High Nickel Alloy FBE Coated Pipe Spool

Largest stockists of Incoloy 925 FBE Coated Spool Pipe, Monel 400 Fusion Bonded Epoxy Coating Pipe Spool, Monel k500 Rubber Lined Pipe Spool, Hastelloy B2 Rubber Lining Pipe Spools, Hastelloy B3 Jacket Piping Spool, Inconel 718 Rubber Lined Pipe Spool, Incoloy 925 Pipe Spool, Incoloy 800 Flanged Spool Pipe, Nickel 201 FBE Coated Pipe Spool, ASTM B336 Nickel Alloy 200 Spool Fittings, Nickel DIN 2.4066 FBE Coated Spool Pipe, Nickel Alloy UNS N02200 Pipe Spool.

Creative Piping Solutions is a Manufacturing and Supplying a good range of optimum quality High Nickel Alloy Piping Spools. Alloy 600 Pipe spools are the rebuilt parts of a piping system. Pipes, flanges, and fittings are called WNR 2.4066 pipe spools, and they are produced before they’re utilized in the piping system. UNS N02200 Pipe spools are reshaped to form easier assemble using hoists, gauges, and other tools for joining the parts. Alloy 625 Pipe spools unite long pipes with flanges from the top of the long pipes in order that they are often bolted with one another with matching flanges. These connections are embedded inside concrete walls before the pouring of concrete.

Hastelloy c22 Fusion Bonded Epoxy Coating Pipe Spool are manufactured using high-quality components and are widely demanded due to their various exclusive feature. These are designed as per international industrial standards, and these are capable of the type the larger and smaller pipe diameters. Fusion Bonded Epoxy (FBE) epoxy coating is meant for corrosion protection of metals.

Hastelloy c276 Rubber Lined Steel Spool Pipe takes steel pipe because of the external skeleton and takes wear resistance, corrosion resistance, and heat resistance rubber because the liner layer, due to rubber physical and chemical properties, can reduce impact, corrosion then on, the rubber buffer, greatly prolongs the service life of the pipeline and reduces the value. Inconel 601 Lined Piping Systems (LPs) are standard products, manufactured consistent with ASTM, DIN, and IS standards.

Nickel Alloy 200 Flanged Pipe Spools are lined with an interference fit. Nickel Alloy 201 Pipe Spool has the pipe Threaded at each end with Threaded and rubbed flanges and screwed into position. All sizes of piping offer vacuum performance with piping up to 6” NB suitable to be used under full vacuum at 200 degrees C. High Nickel Alloy Pipe Spool with one fixed Flange welded to the pipe and one wear loses/rotating flange held in place with a welded collar / Taft end/stub end are quite common and widely specified across all industries.

Creative Piping Solutions is a trusted manufacturers of Pipe Spool, Rubber Lined Pipe Spool, FBE Coating Pipe Spool, Flanged Pipe Spool, Stainless Steel Pipe Spool, Carbon & Alloy Steel Pipe Spool, Duplex & Super Duplex Pipe Spool.

High Nickel Alloy Pipe Spool Specifications

- Type Steel Pipe Spool

- Size 114mm to 2500mm diameter (Seamless & Welded, Fabricated)

- Operating Pressures Maximum 3500kPa

- Maximum Velocities 6m/s for cement mortar lined fittings

- Operating Temperatures -40˚C to 70˚C

- In Form spool

- Standard ANSI / ASME B 36.10 & B 36.19 / ASTM F1545, AS4041:2006 Class 1, ASME IX:2010

- Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40

- Thickness 10s/3 mm to XXS/70 mm

- Specialize As per drawing

- Form Round, Square, Rectangle Hydraulic, Horn Pipe etc.

- Dimensions ANSI / ASME B 36.10 & B 36.19

- Usage/Applications Oil Field, Offshore, Water System, Shipbuilding, Natural Gas, Electric Power, Pipe Projects.

Inconel 600 Pipe Spools Range

| Consturction | Size Range | Schedule / Thickness | |

|---|---|---|---|

| Min Thk (mm) | Max Thk (mm) | ||

| Seamless Fabricated | 0.5″ to 30″ | 10s/3 mm | XXS/85 mm |

| Seamless Fabricated | 0.5″ to 30″ | 10s/3 mm | XXS/85 mm |

| Welded Fabricated | 0.5″ to 48″ | 10s/8 mm | XXS/85 mm |

| Seamless Fabricated | 0.5″ to 24″ | 10s/3 mm | XXS/70 mm |

| Welded Fabricated | 0.5″ to 96″ | 10s/8 mm | XXS/85 mm |

| Welded Fabricated | 0.5″ to 74″ | 10s/6 mm | XXS/70 mm |

ANSI / ASME B 36.10 Hastelloy Pipe Spool Dimensions, Size and Schedule

| DN/NPS (Inch) | OD (mm) | 10 | 20 | 30 | STD | 40 | 60 | XS | 80 | 100 | 120 | 140 | 160 | XXS |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/8 | 10.3 | – | – | – | 1.73 | 1.73 | – | 2.41 | 2.41 | – | – | – | – | – |

| 1/4 | 13.7 | – | – | – | 2.24 | 2.24 | – | 3.02 | 3.02 | – | – | – | – | – |

| 1 | 33.4 | – | – | – | 3.38 | 3.38 | – | 4.55 | 4.55 | – | – | – | 6.35 | 9.09 |

| 1 1/4 | 42.2 | – | – | – | 3.56 | 3.56 | – | 4.85 | 4.85 | – | – | – | 6.35 | 9.7 |

| 1 1/2 | 48.3 | – | – | – | 3.68 | 3.66 | – | 5.08 | 5.08 | – | – | – | 7.14 | 10.15 |

| 3/8 | 17.1 | – | – | – | 2.31 | 2.31 | – | 3.2 | 3.2 | – | – | – | – | – |

| 1/2 | 21.3 | – | – | – | 2.77 | 2.77 | – | 3.73 | 3.73 | – | – | – | 4.78 | 7.47 |

| 3/4 | 26.7 | – | – | – | 2.87 | 2.87 | – | 3.91 | 3.91 | – | – | – | 5.56 | 7.82 |

| 2 | 60.3 | – | – | – | 3.91 | 3.91 | – | 5.54 | 5.54 | – | – | – | 8.74 | 11.07 |

| 2 1/2 | 73 | – | – | – | 5.16 | 5.16 | – | 7.01 | 7.01 | – | – | – | 9.53 | 14.02 |

| 3 | 88.9 | – | – | – | 5.49 | 5.49 | – | 7.62 | 7.62 | – | – | – | 11.13 | 15.24 |

| 3 1/2 | 101.6 | – | – | – | 5.74 | 5.74 | – | 8.08 | 8.08 | – | – | – | – | – |

| 12 | 323.9 | – | 6.35 | 8.38 | 9.53 | 10.31 | 14.27 | 12.7 | 17.48 | 21.44 | 25.4 | 28.58 | 33.32 | 25.4 |

| 14 | 355.6 | 6.35 | 7.92 | 9.53 | 9.53 | 11.13 | 15.09 | 12.7 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | – |

| 16 | 406.4 | 6.35 | 7.92 | 9.53 | 9.53 | 12.7 | 16.66 | 12.7 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | – |

| 18 | 457 | 6.35 | 7.92 | 11.13 | 9.53 | 14.27 | 19.05 | 12.7 | 23.88 | 29.36 | 34.93 | 39.67 | 45.24 | – |

| 20 | 508 | 6.35 | 9.53 | 12.7 | 9.53 | 15.09 | 20.62 | 12.7 | 26.19 | 32.54 | 38.1 | 44.45 | 50.01 | – |

| 22 | 559 | 6.35 | 9.53 | 12.7 | 9.53 | – | 22.23 | 12.7 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | – |

| 24 | 610 | 6.35 | 9.53 | 14.27 | 9.53 | 17.48 | 24.61 | 12.7 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | – |

| 4 | 114.3 | – | – | – | 6.02 | 6.02 | – | 8.56 | 8.56 | – | 11.13 | – | 13.49 | 17.12 |

| 5 | 141.3 | – | – | – | 6.55 | 6.55 | – | 9.53 | 9.53 | – | 12.7 | – | 15.88 | 19.05 |

| 6 | 168.3 | – | – | – | 7.11 | 7.11 | – | 10.97 | 10.97 | – | 14.27 | – | 18.2 | 21.95 |

| 8 | 219.1 | – | 6.35 | 7.04 | 8.18 | 8.18 | 10.31 | 12.7 | 12.7 | 15.09 | 18.26 | 20.62 | 23.01 | 22.23 |

| 10 | 273.1 | – | 6.35 | 7.8 | 9.27 | 9.27 | 12.7 | 12.7 | 15.09 | 18.26 | 21.44 | 25.4 | 28.58 | 25.4 |

| 26 | 660 | 7.92 | 12.7 | – | 9.53 | – | – | 12.7 | – | – | – | – | – | – |

| 28 | 711 | 7.92 | 12.7 | 15.88 | 9.53 | – | – | 12.7 | – | – | – | – | – | – |

| 30 | 762 | 7.92 | 12.7 | 15.88 | 9.53 | – | – | 12.7 | – | – | – | – | – | – |

| 32 | 813 | 7.92 | 12.7 | 15.88 | 9.53 | 17.48 | – | 12.7 | – | – | – | – | – | – |

| 42 | 1067 | – | – | – | 9.53 | – | – | 12.7 | – | – | – | – | – | – |

| 44 | 1118 | – | – | – | 9.53 | – | – | 12.7 | – | – | – | – | – | – |

| 46 | 1168 | – | – | – | 9.53 | – | – | 12.7 | – | – | – | – | – | – |

| 34 | 864 | 7.92 | 12.7 | 15.88 | 9.53 | 17.48 | – | 12.7 | – | – | – | – | – | – |

| 36 | 914 | 7.92 | 12.7 | 15.88 | 9.53 | 19.05 | – | 12.7 | – | – | – | – | – | – |

| 38 | 965 | – | – | – | 9.53 | – | – | 12.7 | – | – | – | – | – | – |

| 40 | 1016 | – | – | – | 9.53 | – | – | 12.7 | – | – | – | – | – | – |

| 48 | 1219 | – | – | – | 9.53 | – | – | 12.7 | – | – | – | – | – | – |

Nickel Alloy 200 Flanged Pipe Spool Dimensions

| To suit pipework NB | Length Min. | Length Max. | PTFE liner Thickness | |

|---|---|---|---|---|

| Inches | mm | mm | mm | mm |

| 1/2″ | 15 | 90 | 6000 | 2.3 |

| 3/4″ | 20 | 90 | 6000 | 3.2 |

| 1″ | 25 | 90 | 6000 | 3.3 |

| 4″ | 100 | 125 | 6000 | 4.5 |

| 6″ | 150 | 140 | 6000 | 5.5 |

| 8″ | 200 | 150 | 3000 | 8.5 |

| 1.1/2″ | 40 | 95 | 6000 | 3.2 |

| 2″ | 50 | 110 | 6000 | 3.2 |

| 3″ | 80 | 120 | 6000 | 3.2 |

| 14″ | 350 | 190 | 3000 | 8.3 |

| 10″ | 250 | 165 | 3000 | 9.1 |

| 12″ | 300 | 170 | 3000 | 10.4 |

Available grades of High Nickel Alloy Pipe Spool

- Nickel Alloy 200 Pipe Spool

- Nickel Alloy 201 Pipe Spool

- Inconel 600 Pipe Spool

- Inconel 601 Pipe Spool

- Inconel 625 Pipe Spool

- Inconel 718 Pipe Spool

- Incoloy 800 Pipe Spool

- Incoloy 825 Pipe Spool

- Incoloy 925 Pipe Spool

- Monel 400 Pipe Spool

- Monel k500 Pipe Spool

- Hastelloy C22 Pipe Spool

- Hastelloy C276 Pipe Spool

- Hastelloy b2 Pipe Spool

Available grades of High Nickel Alloy Flanged Pipe Spool

- Nickel Alloy 200 Flanged Pipe Spool

- Nickel Alloy 201 Flanged Pipe Spool

- Inconel 600 Flanged Pipe Spool

- Inconel 601 Flanged Pipe Spool

- Inconel 625 Flanged Pipe Spool

- Inconel 718 Flanged Pipe Spool

- Incoloy 800 Flanged Pipe Spool

- Incoloy 825 Flanged Pipe Spool

- Incoloy 925 Flanged Pipe Spool

- Monel 400 Flanged Pipe Spool

- Monel k500 Flanged Pipe Spool

- Hastelloy C22 Flanged Pipe Spool

- Hastelloy C276 Flanged Pipe Spool

- Hastelloy b2 Flanged Pipe Spool

Available grades of High Nickel Alloy FBE Coated Pipe Spool

- Nickel Alloy 200 FBE Coated Pipe Spool

- Nickel Alloy 201 FBE Coated Pipe Spool

- Inconel 600 FBE Coated Pipe Spool

- Inconel 601 FBE Coated Pipe Spool

- Inconel 625 FBE Coated Pipe Spool

- Inconel 718 FBE Coated Pipe Spool

- Incoloy 800 FBE Coated Pipe Spool

- Incoloy 825 FBE Coated Pipe Spool

- Incoloy 925 FBE Coated Pipe Spool

- Monel 400 FBE Coated Pipe Spool

- Monel k500 FBE Coated Pipe Spool

- Hastelloy C22 FBE Coated Pipe Spool

- Hastelloy C276 FBE Coated Pipe Spool

- Hastelloy b2 FBE Coated Pipe Spool

Available grades of High Nickel Alloy Rubber Lined Pipe Spool

- Nickel Alloy 200 Rubber Lined Pipe Spool

- Nickel Alloy 201 Rubber Lined Pipe Spool

- Inconel 600 Rubber Lined Pipe Spool

- Inconel 601 Rubber Lined Pipe Spool

- Inconel 625 Rubber Lined Pipe Spool

- Inconel 718 Rubber Lined Pipe Spool

- Incoloy 800 Rubber Lined Pipe Spool

- Incoloy 825 Rubber Lined Pipe Spool

- Incoloy 925 Rubber Lined Pipe Spool

- Monel 400 Rubber Lined Pipe Spool

- Monel k500 Rubber Lined Pipe Spool

- Hastelloy C22 Rubber Lined Pipe Spool

- Hastelloy C276 Rubber Lined Pipe Spool

- Hastelloy b2 Rubber Lined Pipe Spool

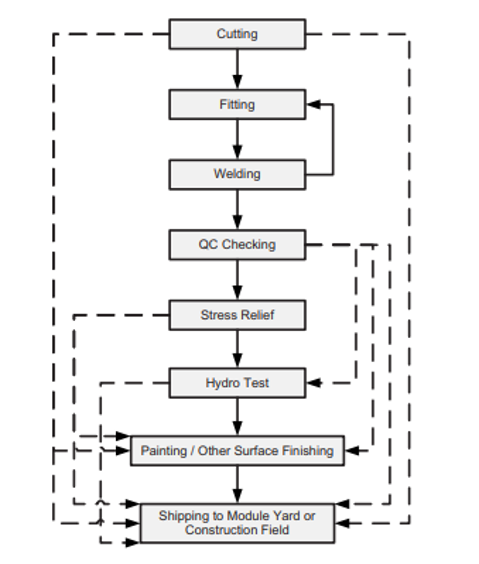

High Nickel Alloy Pipe Spool Manufacturing Process

High Nickel Alloy Flanged Pipe Spool Application Industries

We produce full range of 600 Inconel Spool Pipe in every sizes, pressure / classes, dimensions to meet needs of customers. Our products are well accepted by the majority of customers. it’s widely used in aerospace, shipbuilding, metallurgy, automotive instrumentation, petrochemical, food machinery, biological engineering In the field of environmental protection.

- Refineries

- Food Processing & Dairy

- Oil and Gas Industry

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Power Generation

- Specialty Chemicals

- Sea Water Equipment

- Gas Processing

- Chemical Equipment

- Heat Exchangers

- Petrochemicals

- Pharmaceuticals

- Condensers

High Nickel Alloy FBE Coated Pipe Spool Inspection

We at Creative Piping Solutions ensures that all our materials go through strict quality tests before dispatching them to our clients. we conduct all necessary test of High Nickel Alloy Spool Pipe to assure the quality of deliver products to fit clients projects and needs. NDT test used for High Nickel Alloy Pipe Spool are Positive material identification (PMI), Penetrating liquids, Ferrite content, Hydrostatic test / hydro testing (pressure testing), Magnetic particles, Macrography, Micrography, Pneumatic pressure, Radiography. All of the listed test, the pressure testing is one of the most commonly specified, especially for mission critical fittings in the pipeline.

High Nickel Alloy Flanged Pipe Spool Packing & Forwarding

There are different ways of packing a Hastelloy c22 Rubber Lined Spool Pipe, but two principles that are vital for any method to work prevent rusting and Sea transportation security. Our all products packed with seaworthy packing method then delivery to customers, usually the packing way include wooden box, wooden pallet. We make sure that it is seaworthy, strong, waterproof and easy for loading and unloading. All shipping and product details also stick to outside of package. Hastelloy c276 Fusion Bonded Epoxy Coating Pipe Spool pack with environmental poly bags, and then in free fumigation wooden cases or wooden plate. Hastelloy B2 Jacketed Piping Spool are packed in wooden corrugated boxes foiled in bubble wraps and plastic wraps.

High Nickel Alloy Rubber Lined Pipe Spool Export & Supply to below mentioned Countries

ASIA: Malaysia, India, Taiwan, Cambodia, Singapore, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Myanmar.

SOUTH AMERICA: Venezuela, Argentina, Bolivia, Colombia, Ecuador, Guyana, Paraguay, Uruguay, Brazil, Chile.

AFRICA: South Africa, Nigeria, Algeria, Angola, Libya, Egypt, Gabon, Sudan, Equatorial Guinea, The Republic Of Congo.

NORTH AMERICA: USA, Canada, Mexico, Panama, Costa Rica, Puerto Rico, Trinidad And Tobago, Jamaica, Bahamas, Denmark.

EUROPE: UK, Netherlands, Russia, Norway, Germany, France, Italy, Spain, Ukraine, Belgium, Greece, Hungary, Albania, Austria, Finland, Ireland, Croatia, Slovenia, Malta, Switzerland, Slovakia, Czech Republic, Portugal.