Inconel Stub End Manufacturer, Monel Lap Joint Stub End, Hastelloy Long Stub End Suppliers

ISO Certified Suppliers and Exporters of Nickel 200 Lap Joint Stub Ends, Inconel 600 Long Stub End, Hastelloy c22 Industrial Stub End, Inconel 601 Stub End Pipe Fitting, Hastelloy c276 Short Stub End, Inconel 625 Stub Ends, Incoloy 825 Stub End in India.

Largest stockists of Incoloy 925 Stub End, Monel 400 Buttweld Stub End, Monel k500 Lap Joint Stub Ends, Hastelloy B2 Long Stub End, Hastelloy B3 Buttweld Stub End Pipe Fitting, Inconel 718 Short Stub End, Incoloy 925 Stub Ends, Incoloy 800 Stub End, Nickel 201 Long Stub End, ASTM B336 Nickel Alloy 200 Short Stub End, Nickel DIN 2.4066 Stub Ends, Nickel Alloy UNS N02200 Buttweld Stub End.

Creative Piping Solutions is a leading Manufacturer, Exporter, and Supplier of High Nickel Alloy Stub Ends. We provide our materials with complete certifications, and as per international standards. We will manufacture Alloy 400 Stub Ends up to 48″ with wall thickness starting from 1.5 mm thickness up to 40 mm for various sizes. Alloy k500 Stub End has special quality finishing and duress for long life, high and 0 defects.

Alloy 600 Stub Ends are mechanical joints that consist of two components. Alloy 625 Stub ends are butt weld fittings that will be used alternatively to welding neck flanges to form a flange connection. The utilization of Alloy c276 Stub Ends has two advantages: it can reduce the entire cost of flange joints for piping systems in high material grades.

High Nickel Alloy Stub End Specifications

- Size 1/8″NB TO 48″NB IN

- Schedules SCH5, SCH10, SCH40, SCH STD, SCH 80, SCH 100, SCH 120, SCH 160, SCH XS, SCH XXS

- Dimensions ASME/ANSI B16.9, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313, ASME B16.28

- Forms Long Stub End, Short Stub End, Lap Joint stub end

- Type Seamless / ERW / Welded / Fabricated

- Product’s Angle Bevelled

High Nickel Alloy Stub End Types

Inconel 600 Stub End Dimensions

| NPS | Outside diameter of barrel |

Length (F) | Diameter (G) | Radius (R) | ||

|---|---|---|---|---|---|---|

| Minimum | Maximum | Long Pattern |

Short Pattern |

|||

| 1/2″ | 20.5 | 22.8 | 76 | 51 | 35 | 3 |

| 3/4″ | 25.9 | 28.1 | 76 | 51 | 43 | 3 |

| 2 1/2″ | 72.2 | 75.3 | 152 | 64 | 105 | 8 |

| 3″ | 88.1 | 91.3 | 152 | 64 | 127 | 10 |

| 3 1/2″ | 100.8 | 104.0 | 152 | 76 | 140 | 10 |

| 4″ | 113.5 | 116.7 | 152 | 76 | 157 | 11 |

| 5″ | 140.5 | 144.3 | 203 | 76 | 186 | 11 |

| 6″ | 167.5 | 171.3 | 203 | 89 | 216 | 13 |

| 8″ | 218.3 | 222.1 | 203 | 102 | 270 | 13 |

| 1″ | 32.6 | 35.0 | 102 | 51 | 51 | 3 |

| 1 1/4″ | 41.4 | 43.6 | 102 | 51 | 64 | 5 |

| 1 1/2″ | 47.5 | 49.9 | 102 | 51 | 74 | 6 |

| 2″ | 59.5 | 62.4 | 152 | 64 | 92 | 8 |

| 10″ | 272.3 | 277.2 | 254 | 127 | 324 | 13 |

| 12″ | 323.1 | 328.0 | 254 | 152 | 381 | 13 |

| 14″ | 354.8 | 359.9 | 305 | 152 | 413 | 13 |

| 16″ | 405.6 | 411.0 | 305 | 152 | 470 | 13 |

| 18″ | 456.0 | 462.0 | 305 | 152 | 533 | 13 |

| 20″ | 507.0 | 514.0 | 305 | 152 | 584 | 13 |

| 22″ | 558.0 | 565.0 | 305 | 152 | 641 | 13 |

| 24″ | 609.0 | 616.0 | 305 | 152 | 692 | 13 |

Dimensions of High Nickel Alloy Stub Ends Schedule 10S MSS SP-43 type A/B

| NPS | OD | G | T | F | R Type A |

R Type B |

|---|---|---|---|---|---|---|

| 1/2 | 21.3 | 34.9 | 2.11 | 50.8 | 3.05 | 0.76 |

| 3/4 | 26.7 | 42.9 | 2.11 | 50.8 | 3.05 | 0.76 |

| 2 | 60.3 | 92.1 | 2.77 | 63.5 | 7.87 | 0.76 |

| 2½ | 73 | 104.8 | 3.05 | 63.5 | 7.87 | 0.76 |

| 3 | 88.9 | 127 | 3.05 | 63.5 | 9.65 | 0.76 |

| 1 | 33.4 | 50.8 | 2.77 | 50.8 | 3.05 | 0.76 |

| 1¼ | 42.2 | 63.5 | 2.77 | 50.8 | 4.83 | 0.76 |

| 1½ | 48.3 | 73 | 2.77 | 50.8 | 6.35 | 0.76 |

| 3½ | 101.6 | 139.7 | 3.05 | 76.2 | 9.65 | 0.76 |

| NPS | OD | F | T | G | R Type A |

R Type B |

|---|---|---|---|---|---|---|

| 4 | 114.3 | 76.2 | 3.05 | 157.2 | 11.18 | 0.76 |

| 5 | 141.3 | 76.2 | 3.40 | 185.7 | 11.18 | 1.52 |

| 12 | 323.9 | 152.4 | 4.57 | 381 | 12.7 | 1.52 |

| 14 | 355.6 | 152.4 | 4.78 | 412.8 | 12.70 | 1.52 |

| 16 | 406.4 | 152.4 | 4.78 | 469.9 | 12.7 | 1.52 |

| 6 | 168.3 | 88.9 | 3.40 | 215.9 | 12.7 | 1.52 |

| 8 | 219.1 | 101.6 | 3.76 | 269.9 | 12.7 | 1.52 |

| 10 | 273.1 | 127 | 4.19 | 323.9 | 12.7 | 1.52 |

| 18 | 457.2 | 152.4 | 4.78 | 533.4 | 12.70 | 1.52 |

| 20 | 508 | 152.4 | 5.54 | 584.2 | 12.70 | 1.52 |

| 24 | 609.6 | 152.4 | 6.35 | 692.2 | 12.7 | 1.52 |

Available grades of High Nickel Alloy Stub End

- Nickel Alloy 200 Stub End

- Nickel Alloy 201 Stub End

- Inconel 600 Stub End

- Inconel 601 Stub End

- Inconel 625 Stub End

- Inconel 718 Stub End

- Incoloy 800 Stub End

- Incoloy 825 Stub End

- Incoloy 925 Stub End

- Monel 400 Stub End

- Monel k500 Stub End

- Hastelloy C22 Stub End

- Hastelloy C276 Stub End

- Hastelloy b2 Stub End

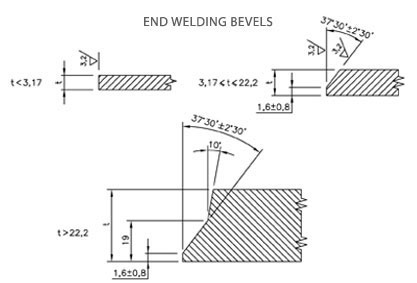

End welding bevels of High Nickel Alloy Stub Ends

| NOMINAL PIPE SIZE (INCHES) | NB | OD | THICKNESS | SCH 10 | SCH 40 | SCH 20 | SCH 30 | SCH 80 |

|---|---|---|---|---|---|---|---|---|

| 1/2 | 15NB | 21.30 | 1.65 | 2.11 | 2.77 | __ | 2.41 | 3.73 |

| 3/4 | 20NB | 26.70 | 1.65 | 2.11 | 2.87 | __ | 2.41 | 3.91 |

| 1 | 25NB | 33.40 | 1.65 | 2.77 | 3.38 | __ | 2.90 | 4.55 |

| 1 1/4 | 32NB | 42.20 | 1.65 | 2.77 | 3.56 | __ | 2.97 | 4.85 |

| 1 1/2 | 40NB | 48.30 | 1.65 | 2.77 | 3.68 | __ | 3.18 | 5.08 |

| 2 | 50NB | 60.30 | 1.65 | 2.77 | 3.91 | __ | 3.18 | 5.54 |

| 2 1/2 | 65NB | 73.00 | 2.11 | 3.05 | 5.16 | __ | 4.78 | 7.01 |

| 3 | 80NB | 88.90 | 2.11 | 3.05 | 5.49 | __ | 4.78 | 7.62 |

| 3 1/2 | 90NB | 101.60 | 2.11 | 3.05 | 5.74 | __ | 4.78 | 8.08 |

| 4 | 100NB | 114.30 | 2.11 | 3.05 | 6.02 | __ | 4.78 | 8.56 |

| 5 | 125NB | 141.30 | 2.77 | 3.40 | 6.55 | __ | __ | 9.53 |

| 6 | 150NB | 168.30 | 2.77 | 3.40 | 7.11 | __ | __ | 10.97 |

| 8 | 200NB | 219.10 | 2.77 | 3.76 | 8.18 | 6.35 | 7.04 | 12.70 |

| 10 | 250NB | 273.00 | 3.40 | 4.19 | 9.27 | 6.35 | 7.80 | 15.09 |

| 12 | 300NB | 323.80 | 3.96 | 4.57 | 10.31 | 6.35 | 8.38 | 17.48 |

| 14 | 350NB | 355.60 | 3.96 | 6.35 | 11.13 | 7.92 | 9.53 | 19.05 |

| 16 | 400NB | 406.40 | 4.19 | 6.35 | 12.7 | 7.92 | 9.53 | 21.44 |

| 18 | 450NB | 457.00 | 4.19 | 6.35 | 14.27 | 7.92 | 11.13 | 23.83 |

| 20 | 500NB | 508.00 | 4.78 | 6.35 | 15.09 | 9.53 | 12.70 | 26.19 |

| 22 | 550NB | 559.00 | 4.78 | 6.35 | __ | 9.53 | 12.70 | 28.58 |

| 24 | 600NB | 610.00 | 5.54 | 6.35 | 17.48 | 9.53 | 14.27 | 30.96 |

High Nickel Alloy Stub Ends Application Industries

We produce full range of 600 Inconel Stub Ends in every sizes, pressure / classes, dimensions to meet needs of customers. Our products are well accepted by the majority of customers. it’s widely used in aerospace, shipbuilding, metallurgy, automotive instrumentation, petrochemical, food machinery, biological engineering In the field of environmental protection.

- Refineries

- Food Processing & Dairy

- Oil and Gas Industry

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Power Generation

- Specialty Chemicals

- Sea Water Equipment

- Gas Processing

- Chemical Equipment

- Heat Exchangers

- Petrochemicals

- Pharmaceuticals

- Condensers

High Nickel Alloy Stub Ends Inspection

We at Creative Piping Solutions ensures that all our materials go through strict quality tests before dispatching them to our clients. we conduct all necessary test of High Nickel Alloy Stub Ends to assure the quality of deliver products to fit clients projects and needs. NDT test used for High Nickel Alloy Stub Ends are Positive material identification (PMI), Penetrating liquids, Ferrite content, Hydrostatic test / hydro testing (pressure testing), Magnetic particles, Macrography, Micrography, Pneumatic pressure, Radiography. All of the listed test, the pressure testing is one of the most commonly specified, especially for mission critical fittings in the pipeline.

High Nickel Alloy Stub Ends Packing & Forwarding

There are different ways of packing a Hastelloy c22 Stub Ends, but two principles that are vital for any method to work prevent rusting and Sea transportation security. Our all products packed with seaworthy packing method then delivery to customers, usually the packing way include wooden box, wooden pallet. We make sure that it is seaworthy, strong, waterproof and easy for loading and unloading. All shipping and product details also stick to outside of package. Hastelloy c276 Stub Ends pack with environmental poly bags, and then in free fumigation wooden cases or wooden plate. Hastelloy B2 Stub Ends are packed in wooden corrugated boxes foiled in bubble wraps and plastic wraps.

High Nickel Alloy Stub Ends Export & Supply to below mentioned Countries

ASIA: Malaysia, India, Taiwan, Cambodia, Singapore, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Myanmar.

SOUTH AMERICA: Venezuela, Argentina, Bolivia, Colombia, Ecuador, Guyana, Paraguay, Uruguay, Brazil, Chile.

AFRICA: South Africa, Nigeria, Algeria, Angola, Libya, Egypt, Gabon, Sudan, Equatorial Guinea, The Republic Of Congo.

NORTH AMERICA: USA, Canada, Mexico, Panama, Costa Rica, Puerto Rico, Trinidad And Tobago, Jamaica, Bahamas, Denmark.

EUROPE: UK, Netherlands, Russia, Norway, Germany, France, Italy, Spain, Ukraine, Belgium, Greece, Hungary, Albania, Austria, Finland, Ireland, Croatia, Slovenia, Malta, Switzerland, Slovakia, Czech Republic, Portugal.