Buttweld Lap Joint Stub End Manufacturer, ANSI/ASME B16.9 Lap Joint Stub Ends Suppliers

ASME/ANSI B16.9, ANSI B16.28, MSS-SP-43 Lap Joint Stub End Suppliers, Check ASME B16.9 Welded Lap Joint Stub End Dimensions & Buttweld Lap Joint Stub End Price List, ASTM A403 SS Lap Joint Stub End, ASME B16.9 Lap Joint Stub End, High-Quality Lap Joint Stub Ends Manufacturer in India.

ASME / ANSI B16.9 Seamless Lap Joint Stub End, High-Quality Buttweld Lap Joint Stub End Exporters in India, Industrial Lap Joint Stub Ends, ANSI/ASME B16.9 Stainless Steel Buttweld Lap Joint Stub End also available in Duplex Steel, Alloy Steel, Hastelloy, Monel, Carbon Steel, Inconel, Titanium, Incoloy, Super Duplex, Alloy 20, 254 SMO, Copper Nickel, High & Low-Temperature Steel, Mild Steel Suppliers in South Africa, Malaysia, Singapore, UK, Philippines, Australia and UAE.

We are a Manufacturer, Supplier, and Exporter of lap joint Stub End that are produced on an outsized scale at our vast in-house manufacturing unit. we’ve been providing trustworthy piping solutions for the past three decades. stainless steel lap joint Stub End is a sort of stub end that’s customarily used with joint flanges, the stub end forming the face of the flange. Applications, where constant disconnection and dismantling of pipes are needed, are benefitted through these fittings as they provide a fast disassembly, allowing inspection and cleaning of pipelines. we provide ANSI B16.9 lap joint Stub Ends that are corrosion resistant besides being reusable and economical, to the petrochemical, fertilizers, power generation, nuclear plants.

Buttweld lap joint Stub End Fittings are mechanical joints that contain Two components: The Stub end, that primarily a quick length of pipe, that has one finish that’s flaring outward and thus, the alternative end able to be welded to the pipe of identical Nominal Pipe Size (NPS), material, and of a uniform wall thickness. lap joint pipe flange slide over the pipe & are most typically used with stub end fittings. A pipe is usually welded to the Stub end, and thus, the lap joint pipe flange is absolved to rotate around the stub end.

ANSI B16.9 Buttweld Lap Joint Stub End Specifications

- Type Industrial Buttweld Lap Joint Stub End

- Size 1/2″~24″ NB. (Seamless & 100% X-Ray Welded, Fabricated)

- In Form Lap Joint Stub Ends, Pipe Stub Ends, Butt weld Lap Joint Stub Ends

- Standard ANSI B16.9, ANSI B16.28, MSS-SP-43

- Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40

- Thickness SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75.

- DIN DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

- BS BS4504 , BS4504, BS1560, BS10

- Specialize As per drawing

- Coating / Surface Treatment Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized

- Connection Type Buttwelding Fittings

- Dimensions ANSI B16.9, ANSI B16.28, MSS-SP-43

- Usage/Applications Oil Field, Offshore, Water System, Shipbuilding, Natural Gas, Electric Power, Pipe Projects etc.

Buttweld Lap Joint Stub End Dimensions

Manufacturing Standards of Buttweld Lap Joint Stub End

| ASME Standard | ASME/ANSI B16.9, ASME/ANSI B16.28, MSS-SP-43 |

|---|---|

| DIN Standard | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| EN Standard | EN10253-2, EN10253-1 |

| ASME B16.25 | Buttwelding Ends |

| ASME B16.9 | Factory-Made Wrought Fittings Buttwelding |

| ASME B16.28 | Wrought Steel Lap Joint Stub End |

| ASTM A403 – ASME SA403 | Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings |

| MSS SP-43 | Wrought & Fabricated Butt-Welding Fitting for Low Pressure, Corrosion Resistant Applications |

ASME / ANSI B16.9 Buttweld Lap Joint Stub End Material & Grades

Stainless Steel Buttweld Lap Joint Stub End :

ASTM A403 WP316/316L, ASTM A403 SA / A 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182 F316L, 304L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Duplex & Super Duplex Steel Lap Joint Stub End :

ASTM A 815, ASME SA 815 UNS NO S31803, S32205. UNS S32750, S32950. Werkstoff No. 1.4462

Carbon Steel Buttweld Lap Joint Stub End :

ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Low Temperature Carbon Steel Lap Joint Stub End : ASTM A420 WPL3, A420 WPL6

Alloy Steel Buttweld Lap Joint Stub End :

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

Nickel Alloy Buttweld Lap Joint Stub End :

ASTM B336, ASME SB336, Nickel 200 (UNS No. No2200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II), Cupro-Nickel 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe.

ASME B16.9 Buttweld Lap Joint Stub End Weight Chart

| NPS inchess |

LAP JOINT STUB ENDS | |||

|---|---|---|---|---|

| Sch. 5S |

Sch. 10S |

Sch. 40S |

Sch. 80S |

|

| 1/2 | 0.06 | 0.08 | 0.12 | 0.13 |

| 3/4 | 0.07 | 0.09 | 0.15 | 0.17 |

| 1 | 0.09 | 0.15 | 0.20 | 0.25 |

| 1 1/4 | 0.13 | 0.20 | 0.30 | 0.35 |

| 1 1/2 | 0.16 | 0.25 | 0.38 | 0.46 |

| 2 | 0.25 | 0.40 | 0.55 | 0.75 |

| 2 1/2 | 0.35 | 0.50 | 0.80 | 1.00 |

| 3 | 0.50 | 0.60 | 1.10 | 1.50 |

| 4 | 0.70 | 1.00 | 1.80 | 2.50 |

| 5 | 1.00 | 1.25 | 2.50 | 3.50 |

| 6 | 1.60 | 1.95 | 3.70 | 5.50 |

| 8 | 2.50 | 3.10 | 5.90 | 10.0 |

| 10 | 4.00 | 4.90 | 10.5 | 14.0 |

| 12 | 6.60 | 7.10 | 15.0 | 20.0 |

| 14 | 6.40 | 7.80 | 15.5 | 20.5 |

| 16 | 7.90 | 9.00 | 18.0 | 24.0 |

| 18 | 9.30 | 10.5 | 21.0 | 28.0 |

| 20 | 12.0 | 13.5 | 23.5 | 31.0 |

| 24 | 16.5 | 19.0 | 28.5 | 38.0 |

| Approximate weights in kg, density 8 kg/dm3 | ||||

ASME B16.9 Lap Joint Stub End Types

Type A

The Type A lap joint Stub end is employed for standard joint flange. The lap thickness on the stub end is bigger than or up to the nominal thickness of pipe wall. Additionally, the outer corner radius of the sort A will receive the lap joint flange. The within corner is square. Lap sometimes includes a machined rough face.

Type B

The Type B lap joint Stub end is employed for standard slip-on flanges as lap flanges. The lap thickness on these short ends is bigger than or up to the nominal thickness of the pipe wall. Also, the outer corner radius of type B is tiny enough to receive the slip o flange which will be used as a backup flange. The inner corner is square. Lap sometimes includes a machined rough face.

Type C

The Type C lap joint Stub end will be used for the standard lap joint flange and put on the flange. It’s flaring feat a rounded edge within the diameter of the lap. If necessary, the radius will be created closed to a square. The lap thickness is 75th of the pipe wall. The sort C is very short enough to accommodate any back up flange. The lap joint on kind C is smooth, and it’s not machined.

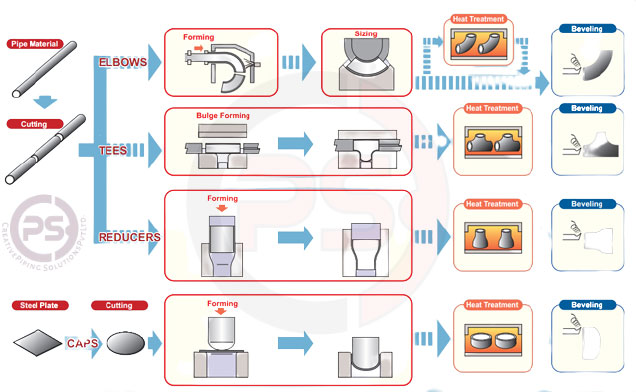

ASME B16.9 Buttweld Lap Joint Stub End Manufacturing Process

The most appropriate Manufacturing Process for every product are going to be decided considerately of its material, sizes, shape, use, standards, and special properties. There are various Pipe Fittings Manufacturing Processes that want to manufacture Lap Joint Stub End, and other pipe Fittings.

One of the foremost common Pipe Fittings Manufacturing Process of Buttweld Lap Joint Stub End from the pipe is a mandrel method which is quite hot forming methods. During this method, The pipe is cut into pieces and push with the assistance of a hydraulic pump. The heating coil heats the pipe and, it’s pushed over a die called, “mandrel” which allows the pipe to expand and bend simultaneously. This method is often wont to manufacture a good range of the diameter of Lap Joint Stub End.

Buttweld Lap Joint Stub End are manufactured from Seamless Pipe and from Welded Pipe with filler materials. Large diameter fittings are manufactured from Plate. We’ve only covered the renowned Pipe Fittings Manufacturing Process here. There are many other methods that used to support the necessities.

Dimensional Tolerances of Buttweld Lap Joint Stub End as per ASME B16.9

| Lap Joint Stub Ends | ||

|---|---|---|

| O.D. of Lap G | Fillet Radius of Lap – R | Overall Length. – F |

| +0 -1 | +0-1 | 2 |

| +0 -1 | +0-1 | 2 |

| +0 -1 | +0 -2 | 2 |

| +0-1 | +0 -2 | 2 |

| +0 -1 | +0 -2 | 2 |

| +0 -2 | +0 -2 | 2 |

| +0 -2 | +0-2 | 3 |

| +0 -2 | +0 -2 | 3 |

Available Types of ASME B16.9 Buttweld Lap Joint Stub End

| Buttweld Lap Joint Stub End | Butt Weld Lap Joint Stub Ends |

| ASME B16.9 Butt weld Lap Joint Stub End | Steel Lap Joint Stub Ends Fittings |

| Stainless Steel Lap Joint Stub End Suppliers | SS Buttweld Lap Joint Stub Ends |

| ANSI B16.9 Buttweld Lap Joint Stub End | ASME B16.28 Buttweld Lap Joint Stub Ends |

| Welded Butt weld Lap Joint Stub Ends | Seamless Butt weld Lap Joint Stub End |

| Carbon Steel Lap Joint Stub End | High Quality Lap Joint Stub End |

| ASTM A403 Stainless Steel Lap Joint Stub Ends | Duplex Steel Buttweld Lap Joint Stub End |

| Super Duplex Steel Buttweld Lap Joint Stub End | Copper Nickel Lap Joint Stub End |

| High Nickel Alloy Lap Joint Stub Ends | Hastelloy Lap Joint Stub Ends |

| Titanium Buttweld Lap Joint Stub End | Inconel Butt weld Lap Joint Stub End |

Butt weld Lap Joint Stub End Application Industries

- Refineries

- Food Processing & Dairy

- Oil and Gas Industry

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Power Generation

- Specialty Chemicals

- Sea Water Equipment

- Gas Processing

- Chemical Equipment

- Heat Exchangers

- Petrochemicals

- Pharmaceuticals

- Condensers

Butt Weld Lap Joint Stub End Inspection

All Buttweld Lap Joint Stub End are inspected and tested in accordance with the relevant product standard (eg. ASME/ANSI B16.9, ANSI B16.28, MSS-SP-43) or code and as stated in the Purchase requisition. Pressure testing or Hydro-testing of Stainless Steel Lap Joint Stub End where required by the standard shall be performed using water having less than 30ppm of chlorides. All welds in welded buttweld pipe fittings shall be 100% radiographed in accordance with the individual ASTM Standard. In lieu of radiography, Ultrasonic examination is not allowed. Examinations and/or tests may be reviewed and / or witnessed by the contractor or their authorized third party inspector at our facility. We are responsible for informing the contractor about the availability of goods for inspection and testing. Inspection is performed as per “Vendor Quality Requirement form” attached with the Inquiry / Purchase requisition. As a manufacturer, we submit the certificate of conformity of the material duly certified by inspector.

Buttweld Lap Joint Stub End Packing & Forwarding

Seamless Lap Joint Stub End are packed ready for export in a manner which allows easy handling and prevents damage. We submit our standard packing procedure to purchaser for approval. Open ends of Buttweld Lap Joint Stub End are supplied with heavy duty plastic protective plugs or caps. For bevelled ends, we insure that caps can protect the full area of the bevel. All material up to 6” in sizes shall be supplied in wooden boxes or cartons and as appropriate and adequately strapped. Buttweld Lap Joint Stub End Fittings over 6” shall be supplied on wooden pallets with metal straps. Also, the pallets shall be shrink wrapped. All shipping documentation is provided for seamless delivery from mill to purchaser.

ANSI/ASME B16.9 Buttweld Lap Joint Stub End Export & Supply to below mentioned Countries

ASIA: Malaysia, India, Taiwan, Cambodia, Singapore, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Myanmar.

SOUTH AMERICA: Venezuela, Argentina, Bolivia, Colombia, Ecuador, Guyana, Paraguay, Uruguay, Brazil, Chile.

AFRICA: South Africa, Nigeria, Algeria, Angola, Libya, Egypt, Gabon, Sudan, Equatorial Guinea, The Republic Of Congo.

NORTH AMERICA: USA, Canada, Mexico, Panama, Costa Rica, Puerto Rico, Trinidad, and Tobago, Jamaica, Bahamas, Denmark.

EUROPE: UK, Netherlands, Russia, Norway, Germany, France, Italy, Spain, Ukraine, Belgium, Greece, Hungary, Albania, Austria, Finland, Ireland, Croatia, Slovenia, Malta, Switzerland, Slovakia, Czech Republic, Portugal.