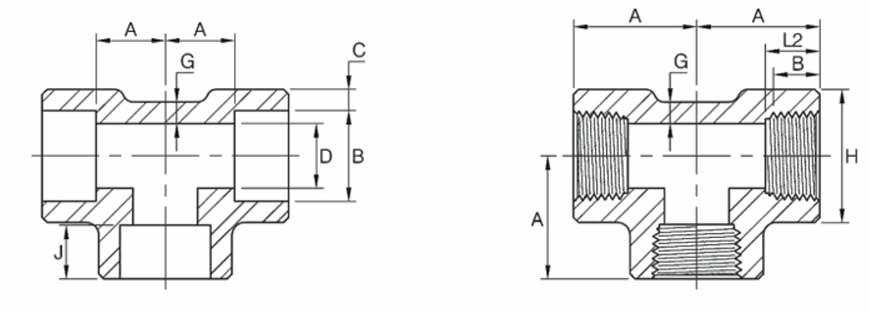

ASME B16.11 Tee Dimensions

Dimensions in Millimeters.

| Socket Welding | |||||||

| DN | Nom. Pipe Size |

B(2) | c(1) (Avg) (Min) |

D(2) | A(2) | G (Min) |

J (Min) |

3000Lb

| 6 | 1/8 | 10.8 | 3.18 | 3.18 | 6.9 | 11.0 | 2.41 | 9.5 |

| 8 | 1/4 | 14.2 | 3.78 | 3.30 | 9.3 | 11.0 | 3.02 | 9.5 |

| 10 | 3/8 | 17.6 | 4.01 | 3.50 | 12.6 | 13.5 | 3.20 | 9.5 |

| 15 | 1/2 | 21.8 | 4.67 | 4.09 | 15.8 | 15.5 | 3.73 | 9.5 |

| 20 | 3/4 | 27.2 | 4.90 | 4.27 | 21.0 | 19.0 | 3.91 | 12.5 |

| 25 | 1 | 33.9 | 5.69 | 4.98 | 26.7 | 22.5 | 4.55 | 12.5 |

| 32 | 1-1/4 | 42.7 | 6.07 | 5.28 | 35.1 | 27.0 | 4.85 | 12.5 |

| 40 | 1-1/2 | 48.8 | 6.35 | 5.54 | 40.9 | 32.0 | 5.08 | 12.5 |

| 50 | 2 | 61.2 | 6.93 | 6.04 | 52.5 | 38.0 | 5.54 | 16.0 |

| 65 | 2-1/2 | 73.9 | 8.76 | 7.87 | 62.7 | 41.0 | 7.01 | 16.0 |

| 80 | 3 | 89.8 | 9.52 | 8.30 | 78.0 | 57.0 | 7.62 | 16.0 |

| 100 | 4 | 115.2 | 10.69 | 9.35 | 102.3 | 66.5 | 8.56 | 19.0 |

6000Lb

| 6 | 1/8 | 10.8 | 3.96 | 3.43 | 4.0 | 11.0 | 3.15 | 9.5 |

| 8 | 1/4 | 14.2 | 4.60 | 4.01 | 6.4 | 13.5 | 3.68 | 9.5 |

| 10 | 3/8 | 17.6 | 5.03 | 4.37 | 9.2 | 15.5 | 4.01 | 9.5 |

| 15 | 1/2 | 21.8 | 5.97 | 5.18 | 11.8 | 19.0 | 4.78 | 9.5 |

| 20 | 3/4 | 27.2 | 6.96 | 6.04 | 15.6 | 22.5 | 5.56 | 12.5 |

| 25 | 1 | 33.9 | 7.92 | 6.93 | 20.7 | 27.0 | 6.35 | 12.5 |

| 32 | 1-1/4 | 42.7 | 7.92 | 6.93 | 29.5 | 32.0 | 6.35 | 12.5 |

| 40 | 1-1/2 | 48.8 | 8.92 | 7.80 | 34.0 | 38.0 | 7.14 | 12.5 |

| 50 | 2 | 61.2 | 10.92 | 9.50 | 42.9 | 41.0 | 8.74 | 16.0 |

9000Lb

| 15 | 1/2 | 21.8 | 9.35 | 8.18 | 6.4 | 25.5 | 7.47 | 9.5 |

| 20 | 3/4 | 27.2 | 9.78 | 8.56 | 11.1 | 28.5 | 7.82 | 12.5 |

| 25 | 1 | 33.9 | 11.38 | 9.96 | 15.2 | 32.0 | 9.09 | 12.5 |

| 32 | 1-1/4 | 42.7 | 12.14 | 10.62 | 22.8 | 35.0 | 9.70 | 12.5 |

| 40 | 1-1/2 | 48.8 | 12.70 | 11.12 | 28.0 | 38.0 | 10.15 | 12.5 |

| 50 | 2 | 61.2 | 13.84 | 12.12 | 38.2 | 54.0 | 11.07 | 16 0 |

(1) Average socket wall Thickness around the periphery shall be no less than the listed values. The minimum values are permitted in localized areas

Dimensions in Millimeters.

| Threaded | ||||||

| DN | Norm Pipe Size |

Length of Thread. | A | G (Min) |

H | |

| B | L2 | |||||

2000Lb

| 6 | 1/8 | 6.4 | 6.7 | 21 | 3.18 | 22 |

| 8 | 1/4 | 8.1 | 10.2 | 21 | 3.18 | 22 |

| 10 | 3/8 | 9.1 | 10.4 | 25 | 3.18 | 25 |

| 15 | 1/2 | 10.9 | 13.6 | 28 | 3.18 | 33 |

| 20 | 3/4 | 12.7 | 13.9 | 33 | 3.18 | 38 |

| 25 | 1 | 14.7 | 17.3 | 38 | 3.68 | 46 |

| 32 | 1-1/4 | 17.0 | 18.0 | 44 | 3.89 | 56 |

| 40 | 1-1/2 | 17.8 | 18.4 | 51 | 4.01 | 62 |

| 50 | 2 | 19.0 | 19.2 | 60 | 4.27 | 75 |

| 65 | 2-1/2 | 23.6 | 28.9 | 76 | 5.61 | 92 |

| 80 | 3 | 25.9 | 30.5 | 86 | 5.99 | 109 |

| 100 | 4 | 27.7 | 33.0 | 106 | 6.55 | 146 |

3000Lb

| 5 | 1/8 | 6.4 | 6.7 | 21 | 3.18 | 22 |

| 8 | 1/4 | 8.1 | 10.2 | 25 | 3.30 | 25 |

| 10 | 3/8 | 9.1 | 10.4 | 28 | 3.51 | 33 |

| 15 | 1/2 | 10.9 | 13.6 | 33 | 4.09 | 38 |

| 20 | 3/4 | 12.7 | 13.9 | 38 | 4.32 | 46 |

| 25 | 1 | 14.7 | 17.3 | 44 | 4.98 | 56 |

| 32 | 1-1/4 | 17.0 | 18.0 | 51 | 5.28 | 62 |

| 40 | 1-1/2 | 17.8 | 18.4 | 60 | 5.56 | 75 |

| 50 | 2 | 19.0 | 19.2 | 64 | 7.14 | 84 |

| 65 | 2-1/2 | 23.6 | 28.9 | 83 | 7.65 | 102 |

| 80 | 3 | 25.9 | 30.5 | 95 | 8.84 | 121 |

| 100 | 4 | 27.7 | 33.0 | 114 | 11.18 | 152 |

6000Lb

| 6 | 1/8 | 6.4 | 6.7 | 25 | 6.35 | 25 |

| 8 | 1/4 | 8.1 | 10.2 | 28 | 6.60 | 33 |

| 10 | 3/8 | 9.1 | 10.4 | 33 | 6.98 | 38 |

| 15 | 1/2 | 10.9 | 13.6 | 38 | 8.15 | 46 |

| 20 | 3/4 | 12.7 | 13.9 | 44 | 8.53 | 56 |

| 25 | 1 | 14.7 | 17.3 | 51 | 9.93 | 62 |

| 32 | 1-1/4 | 17.0 | 18.0 | 60 | 10.59 | 75 |

| 40 | 1-1/2 | 17.8 | 18.4 | 64 | 11.07 | 84 |

| 50 | 2 | 19.0 | 19.2 | 83 | 12.09 | 102 |

| 65 | 2-1/2 | 23.6 | 28.9 | 95 | 15.29 | 121 |

| 80 | 3 | 25.9 | 30.5 | 106 | 16.64 | 146 |

| 100 | 4 | 27.7 | 33.0 | 114 | 18.67 | 152 |

Dimension B is the minimum length of the perfect thread. The length Of useful thread (B plus Threads with fully formed roots and flat crests) shall not be less than the L2 Reflective length of external thread)required by American National Standard for pipe threads (ANSI ASME B1.20.1).

Get Complete Details of Forged Fittings Here