Carbon Steel Mitered Pipe Bends Manufacturer, Alloy Steel Long Radius Mitered Pipe Bends Suppliers

ISO Certified Suppliers and Exporters of ASTM A105 / A105N Carbon Steel Miter Bend, ASTM A335 Alloy Steel GR P1 Mitered Pipe Bends, ASTM A335 Alloy Steel GR P5 Industrial Miter Pipe Bend, ASTM A335 Alloy Steel GR P9 Miter Bends, ASME SA 335 Alloy Steel K91560 Mitered Pipe Bends, Carbon Steel ASTM A105 Mitre Bend Pipe, ASTM A105 Carbon Steel Buttweld Mitered Pipe Bends in India.

Largest stockists of ASTM A335 Alloy Steel GR P91 Long Radius Miter Bend, ASME SA 335 Alloy Steel Long Radius Mitered Pipe Bends, ASME SA105 Carbon Steel Long Radius Miter Bends, Carbon Steel Long Radius Mitered Pipe Bends, ASTM A105 Carbon Steel Long Radius Mitre Bend Pipe, ASME B16.11 Carbon Steel Long Radius Mitered Bends, ANSI B16.11 Carbon Steel Long Radius Buttweld Mitered Pipe Bends, Carbon Steel Long Radius Mitered Bend, Alloy Steel 1.7386 Mitered Pipe Bends.

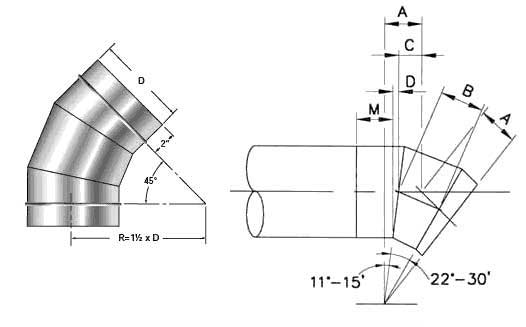

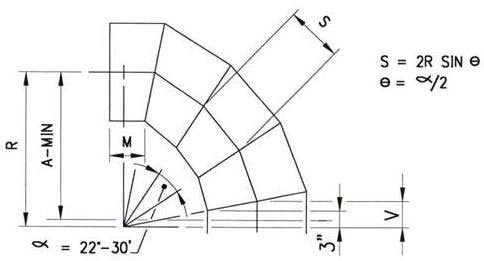

Creative Piping Solutions are a foremost Manufacturer, Supplier, and Exporter of providing an honest assortment of Carbon Steel Mitered Bend. Alloy Steel Miter Bend or Miter Elbow is ready by mitering (angle cutting) and welding pipe ends of the cut-pieces, usually at a 45° and 90° to make a corner. There are two sorts of miter bend, one non-perpendicular bend & another is 3-D bend. ASTM A105 Carbon Steel Miter Elbow/Bend is formed from miter cut pieces of pipe. The Miter pieces also called gores, There are two end gores and two middle gores during a 4-piece Miter bend. ASTM A335 Alloy Steel Miter bend is a bend that is formed by cutting pipe ends at an angle and joining the pipe ends.

Carbon Steel Long Radius Miter Bend or Long Radius Miter Elbow is ready by mitering (angle cutting) and welding pipe ends of the cut-pieces, usually at a 45° and 90° to make a corner. There are two sorts of miter bend, one non-perpendicular bend & another is 3-D bend. Alloy Steel Long Radius Miter Elbow/Bend is formed from miter cut pieces of pipe. The Miter pieces are also called gores, There are two end gores and two middle gores during a 4-piece Miter bend. Alloy Steel Long Radius Miter bend is a bend that is formed by cutting pipe ends at an angle and joining the pipe ends.

Carbon Steel / Alloy Steel Mitered Pipe Bends Specifications

- Size 1/2″NB TO 48″NB IN

- Type Seamless / ERW / Welded / Fabricated

- Dimensions ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

- Bend Radii Cast Iron

- Bending Radius(R) R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

- Bending angle (θ) 15°, 30°, 45°, 60°, 90°, 135°, 180°

Carbon Steel Mitered Bend Dimensions

| NOM. SIZE | DIMENSIONS IN MM | ||||

|---|---|---|---|---|---|

| D 1) | OD | R | A | B | C |

| 2″ | 60.33 | 50 | 32 | 8 | 12 |

| 3″ | 88.90 | 80 | 49 | 14 | 17.5 |

| 4″ | 114.30 | 100 | 62 | 17 | 22.5 |

| 6″ | 168.28 | 150 | 93 | 26 | 33.5 |

| 8″ | 219.08 | 200 | 123 | 36 | 43.5 |

| 10″ | 273.05 | 250 | 153 | 45 | 54 |

| 12″ | 323.85 | 300 | 183 | 55 | 64 |

| 14″ | 356 | 350 | 210 | 68 | 71 |

| 16″ | 406 | 400 | 240 | 78 | 81 |

| 18″ | 457 | 450 | 270 | 88 | 91 |

| 20″ | 508 | 500 | 300 | 98 | 101 |

| 24″ | 610 | 600 | 360 | 117 | 121.5 |

| 26″ | 660 | 660 | 393 | 131 | 131 |

| 28″ | 711 | 700 | 420 | 137 | 141.5 |

| 38″ | 965 | 965 | 576 | 192 | 192 |

| 30″ | 762 | 760 | 454 | 151 | 151.5 |

| 32″ | 813 | 800 | 479 | 156 | 161.5 |

| 34″ | 864 | 860 | 514 | 170 | 172 |

| 36″ | 914 | 910 | 544 | 180 | 182 |

| 40″ | 1016 | 1020 | 607 | 203 | 202 |

Alloy Steel Long Radius Mitered Bend Dimensions

| NOM. DIA |

A Min. | R Radius |

S Inches |

M |

|---|---|---|---|---|

| 30 | 42w” | 45″ | 17p” | |

| 32 | 44s” | 48″ | 18s” | |

| 34 | 47r” | 51″ | 19f” | |

| 36 | 49f” | 54″ | 21w” | |

| 38 | 52i” | 57″ | 22r” | |

| 40 | 55w” | 60″ | 23i” | |

| 42 | 57s” | 63″ | 24p” | 8r” |

| 44 | 60r” | 66″ | 25s” | |

| 46 | 62f” | 69″ | 27″ | |

| 48 | 65i” | 72″ | 28i” | 9p” |

| 50 | 68w” | 75″ | 29r” | |

| 52 | 70s” | 78″ | 30i” | |

| 54 | 73r” | 81″ | 31p” | 10f” |

| 56 | 75f” | 84″ | 32f” | |

| 58 | 78i” | 87″ | 34″ | |

| 60 | 81w” | 90″ | 35w” | |

| 62 | 83s” | 93″ | 36y” | |

| 64 | 86y” | 96″ | 37i” | |

| 66 | 88f” | 99″ | 38p” | |

| 68 | 91i” | 102″ | 39f” | |

| 70 | 94w” | 105″ | 41″ | |

| 72 | 96s” | 108″ | 42r” | |

| 78 | 104i” | 117″ | 45s” | 15r” |

| 84 | 112y” | 126″ | 49i” | |

| 86 | 115″ | 129″ | 50y” |

Available grades of Carbon Steel / Alloy Steel Mitered Pipe Bends

- Carbon Steel ASTM A105 Mitered Pipe Bends

- ASTM A335 Alloy Steel Mitered Pipe Bends

- CrMo P1 Mitered Pipe Bends

- Chrome Moly P91 Mitered Pipe Bends

- P22 Alloy Steel Mitered Pipe Bends

- Alloy Steel P1 Mitered Pipe Bends

- Alloy Steel P91 Mitered Pipe Bends

- Alloy steel p12 Mitered Pipe Bends

- Chrome Moly P22 Mitered Pipe Bends

- ASTM A182 Alloy Steel N10665 Mitered Pipe Bends

- CrMo P91 Mitered Pipe Bends

- ASTM A335 Alloy Steel GR P11 Mitered Pipe Bends

- ASME SA 335 Alloy Steel Grade P1 Mitered Pipe Bends

- ASTM A335 Alloy Steel GR P91 Mitered Pipe Bends

Carbon Steel Mitered Pipe Bends Application Industries

We produce full range of Carbon Steel Mitered Bends in every sizes, pressure / classes, dimensions to meet needs of customers. Our products are well accepted by the majority of customers. it’s widely used in aerospace, shipbuilding, metallurgy, automotive instrumentation, petrochemical, food machinery, biological engineering In the field of environmental protection.

- Refineries

- Food Processing & Dairy

- Oil and Gas Industry

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Power Generation

- Specialty Chemicals

- Sea Water Equipment

- Gas Processing

- Chemical Equipment

- Heat Exchangers

- Petrochemicals

- Pharmaceuticals

- Condensers

Alloy Steel Mitered Pipe Bends Inspection

We at Creative Piping Solutions ensures that all our materials go through strict quality tests before dispatching them to our clients. we conduct all necessary test of Carbon Steel Mitered Bends to assure the quality of deliver products to fit clients projects and needs. NDT test used for Alloy Steel Mitered Pipe Bend are Positive material identification (PMI), Penetrating liquids, Ferrite content, Hydrostatic test / hydro testing (pressure testing), Magnetic particles, Macrography, Micrography, Pneumatic pressure, Radiography. All of the listed test, the pressure testing is one of the most commonly specified, especially for mission critical fittings in the pipeline.

Carbon Steel Mitered Pipe Bends Packing & Forwarding

There are different ways of packing a Alloy Steel Mitered Bends, but two principles that are vital for any method to work prevent rusting and Sea transportation security. Our all products packed with seaworthy packing method then delivery to customers, usually the packing way include wooden box, wooden pallet. We make sure that it is seaworthy, strong, waterproof and easy for loading and unloading. All shipping and product details also stick to outside of package. Carbon Steel A105 Mitered Bends pack with environmental poly bags, and then in free fumigation wooden cases or wooden plate. ASTM A335 Alloy Steel Mitered Pipe Bends are packed in wooden corrugated boxes foiled in bubble wraps and plastic wraps.

Carbon Steel Mitered Pipe Bends Export & Supply to below mentioned Countries

ASIA: Malaysia, India, Taiwan, Cambodia, Singapore, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Myanmar.

SOUTH AMERICA: Venezuela, Argentina, Bolivia, Colombia, Ecuador, Guyana, Paraguay, Uruguay, Brazil, Chile.

AFRICA: South Africa, Nigeria, Algeria, Angola, Libya, Egypt, Gabon, Sudan, Equatorial Guinea, The Republic Of Congo.

NORTH AMERICA: USA, Canada, Mexico, Panama, Costa Rica, Puerto Rico, Trinidad, And Tobago, Jamaica, Bahamas, Denmark.

EUROPE: UK, Netherlands, Russia, Norway, Germany, France, Italy, Spain, Ukraine, Belgium, Greece, Hungary, Albania, Austria, Finland, Ireland, Croatia, Slovenia, Malta, Switzerland, Slovakia, Czech Republic, Portugal.