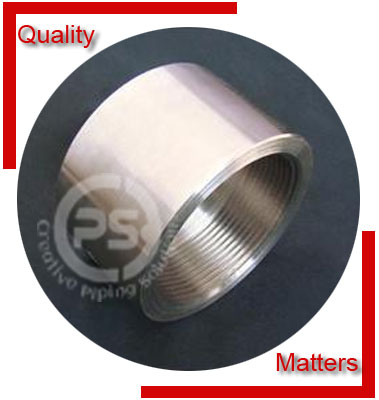

Threaded Pipe Cap Manufacturer, ANSI/ASME B16.11 Threaded End Cap Suppliers

ASME/ANSI B16.11, MSS SP-79, 83, 95, 97, BS 3799 Forged Threaded Pipe Cap Suppliers, Check ASME B16.11 Threaded Welded End Cap Dimensions & Threaded Pipe Cap Price List, ASTM A182 Stainless Steel Threaded End Cap, ASME B16.11 Threaded End Pipe Cap, High-Quality Threaded Cap Manufacturer in India.

ASME / ANSI B16.11 Threaded End Cap, High-Quality Threaded Pipe Cap Exporters in India, Industrial Threaded End Cap, ANSI/ASME B16.11 Stainless Steel Threaded Cap also available in Duplex Steel, Alloy Steel, Hastelloy, Monel, Carbon Steel, Inconel, Titanium, Incoloy, Super Duplex, Alloy 20, 254 SMO, Copper Nickel, High & Low-Temperature Steel, Mild Steel Suppliers in South Africa, Malaysia, Singapore, UK, Philippines, Australia and UAE.

Creative Piping Solutions is recognized as one of the foremost eminent Manufacturers, Suppliers, and Exporters of premium quality ASME B16.11 Threaded End Pipe Cap. Our supplied forged threaded end cap can sustain a high-temperature rating. ASME B16.11 Threaded Pipe Cap is understood to deliver exceptional performance and is usually developed for meeting the demands. It is commonly utilized in the oil and gas industry, petrochemical industries, energy projects, hydraulics, and pneumatic industries.

ASME B16.11 Threaded Pipe End Caps Seals the threaded end of the pipe. It acts as a protective device and is intended to protect pipe ends of various shapes. the foremost purpose of using Threaded pipe caps is to waterproof the connections. They’re also used to close the ends of hydraulic, or pneumatic pipes. the most purpose of using these caps is to possess waterproof connections. they’re used for the aim of closing the ends of the pneumatic also as hydraulic tubing or piping system.

ANSI B16.11 Threaded Pipe Cap Specifications

- Forged Type Threaded Pipe Fittings

- Threaded Size 1/8″~4″ (DN6~DN100)

- Threaded Pressure Class 2000LBS, 3000LBS, 6000LBS, 9000LBS

- Threaded Dimension ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

- Threads ISO, DIN, NPT, BSPT

- Threaded Form Threaded Pipe Cap

Threaded End Pipe Cap Dimensions

Manufacturing Standards of Threaded Pipe Cap

- ASME B16.11 – Threadeding and Threaded Forged Fittings.

- MSS SP-43 – Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications.

- MSS SP-95 – Swage(d) Nipples and Bull Plugs.

- BS3799 – Specification for Steel pipe fittings, screwed Threaded for the petroleum industry.

- ASTM A182 – ASME SA182 – Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings.

ASME / ANSI B16.11 Threaded Pipe Cap Material & Grades

Stainless Steel Threaded Pipe Cap :

ASTM A182 WP316/316L, ASTM A182 SA / A 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182 F316L, 304L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Duplex & Super Duplex Steel Threaded Pipe Cap :

ASTM A 815, ASME SA 815 UNS NO S31803, S32205. UNS S32750, S32950. Werkstoff No. 1.4462

Carbon Steel Threaded Pipe Cap :

ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Low Temperature Carbon Steel Threaded Pipe Cap : ASTM A420 WPL3, A420 WPL6

Alloy Steel Threaded Pipe Cap :

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

Nickel Alloy Threaded Pipe Cap :

ASTM B336, ASME SB336, Nickel 200 (UNS No. No2200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II), Cupro-Nickel 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe.

Angularity Tolerances of Threaded Pipe Cap as per ASME B16.11

| ND | Max off angle | Max off plane |

|---|---|---|

| Q | P | |

| 1/2 a 4 | 1 | 2 |

| 5 a 8 | 2 | 4 |

| 10 a 12 | 3 | 5 |

| 14 a 16 | 3 | 7 |

| 18 a 24 | 4 | 10 |

| 26 a 30 | 5 | 10 |

| 32 a 42 | 5 | 13 |

| 44 a 48 | 5 | 20 |

Available Types of ASME B16.11 Threaded End Cap

| Forged Threaded Pipe Cap | Threaded Pipe Cap |

| 150 lb. Threaded Fittings Pipe Cap | Threaded Forged Cap |

| ASME B16.11 Forged Threaded Pipe Cap | Forged Pipe Caps 3000LB Threaded |

| Stainless Steel Threaded Pipe Cap | SS Forged Threaded Pipe Cap |

| ANSI B16.11 Forged Threaded Pipe Cap | BS 3799 Forged Threaded Pipe Caps |

| Forged Threaded Pipe Cap | Threaded Forged Pipe Cap |

| Carbon Steel Threaded Pipe Cap | High Quality Threaded Pipe Cap |

| ASTM A182 Threaded SS Pipe Cap | Duplex Steel Threaded Pipe Cap |

| Super Duplex Steel Threaded End Pipe Caps | Copper Nickel Threaded Pipe Cap |

| High Nickel Alloy Forged Threaded Pipe Cap | Hastelloy Threaded Pipe Cap |

| Titanium Forged Threaded Pipe Cap | Inconel Threaded Pipe Caps |

Threaded End Pipe Cap Manufacturing Process

Forged Threaded Pipe Cap Application Industries

- Refineries

- Food Processing & Dairy

- Oil and Gas Industry

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Power Generation

- Specialty Chemicals

- Sea Water Equipment

- Gas Processing

- Chemical Equipment

- Heat Exchangers

- Petrochemicals

- Pharmaceuticals

- Condensers

Forged Threaded Pipe Cap Inspection

All Threaded Pipe Cap are inspected and tested in accordance with the relevant product standard (ASME/ANSI B16.11, MSS-SP-79) or code and as stated in the Purchase requisition. Pressure testing or Hydro-testing of Stainless Steel Threaded End Cap where required by the standard shall be performed using water having less than 30ppm of chlorides. All welds in welded Threaded pipe fittings shall be 100% radiographed in accordance with the individual ASTM Standard. In lieu of radiography, Ultrasonic examination is not allowed. Examinations and/or tests may be reviewed and / or witnessed by the contractor or their authorized third party inspector at our facility. We are responsible for informing the contractor about the availability of goods for inspection and testing. Inspection is performed as per “Vendor Quality Requirement form” attached with the Inquiry / Purchase requisition. As a manufacturer, we submit the certificate of conformity of the material duly certified by inspector.

Threaded End Pipe Cap Packing & Forwarding

Threaded Pipe Cap are packed ready for export in a manner which allows easy handling and prevents damage. We submit our standard packing procedure to purchaser for approval. Open ends of Threaded End Cap are Supplied with heavy duty plastic protective plugs or caps. For bevelled ends, we insure that caps can protect the full area of the bevel. All material up to 6” in sizes shall be supplied in wooden boxes or cartons and as appropriate and adequately strapped. Forged Threaded End Pipe Cap Pipe Fittings over 6” shall be supplied on wooden pallets with metal straps. Also, the pallets shall be shrink wrapped. All shipping documentation is provided for seamless delivery from mill to purchaser.

ANSI/ASME B16.11 Threaded Pipe Cap Export & Supply to below mentioned Countries

ASIA: Malaysia, India, Taiwan, Cambodia, Singapore, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Myanmar.

SOUTH AMERICA: Venezuela, Argentina, Bolivia, Colombia, Ecuador, Guyana, Paraguay, Uruguay, Brazil, Chile.

AFRICA: South Africa, Nigeria, Algeria, Angola, Libya, Egypt, Gabon, Sudan, Equatorial Guinea, The Republic Of Congo.

NORTH AMERICA: USA, Canada, Mexico, Panama, Costa Rica, Puerto Rico, Trinidad, and Tobago, Jamaica, Bahamas, Denmark.

EUROPE: UK, Netherlands, Russia, Norway, Germany, France, Italy, Spain, Ukraine, Belgium, Greece, Hungary, Albania, Austria, Finland, Ireland, Croatia, Slovenia, Malta, Switzerland, Slovakia, Czech Republic, Portugal.