Double Flanged Pipe Manufacturer, Double Flanged End Butterfly Valve Suppliers

Ductile Iron Double Flanged Pipe Suppliers, Check Double Flanged Butterfly Valve Dimensions & DI Double Flanged Pipe Price List, Cast Iron Double Flanged Pipes, Double Flanged Butterfly Valve PTFE Lined Manufacturer in India

Double Flanged Butterfly Valve PTFE Lined Exporters in India, CI Double Flanged Pipe, Double Flanged Bend, Double Flanged Bend, Double Flanged Butterfly Valves PN 10, CI Double Flanged Pipe Suppliers in South Africa, Malaysia, Singapore, UK, Philippines, and Australia.

Creative Piping Solutions is a Manufacturer and Supplier of Ductile iron double Flange Pipes. We are able to produce 100% X-Ray Tested (100% Radiography) fabricated Double Flange Pipe in various alloys including stainless steel, carbon steel, alloy steel, and nickel-base alloy grades like 304, 316, 316L, 904L, 321, 347, 317L, Alloy 200 / 201, Alloy 400, Alloy 600 / 625, Alloy C276. Quality control is extensively applied by our inspection team to make sure that 100% of our products are produced to satisfy all the dimensions and specification requirements of our customers.

Double Flange is a big size resilient seated kind of valve available in double-flanged body styles from 8”(DN200) to 48”(DN1200). variety of actuators available: Manual operators (worm gears), pneumatic rotary quarter-turn actuator, electric actuators, and everyone associated accessories. Applications: water system networks, Water treatment and pumping, Power generation, cooling water systems (fresh or seawater).

A Double Flanges Pipe is formed of a welded/seamless steel pipe with mating flanges welded to every end. The mating flanges are often either slip-on/plate(two welding seams) or weld neck(one welding seams) type. In a prefabricated pipe conduit system, precise axial alignment of bolt holes between two end flanges is extremely important. Sometimes butt weld pipe fittings in conformance to ASME/ANSI B16.9 or EN 10253 might not meet this requirement, especially for sizes smaller than 4.” Extension of the radius of elbow or length of tee outlet is important.

Double Flanged Pipe Specifications

- Size Range 2″ (DN50) to 48″ (DN1200)

- Design & Manufacture BS 67655-I / API 598

- Body Design Double Flange

- Body Cast iron, Ductile iron, Carbon Steel, Stainless Steel

- Disc Cast iron, Ductile iron, Carbon Steel, Stainless Steel

- Stem Stainless Steel

- Seat EPDM/NBR/Viton/Silicon/Nitrile/NEOPRENE

- Operation Hand Lever, Gar, Pneumatic, Electrical Actuator

- Temperature Capacity -10 degree to 200 degree

- Connection Flange Type

- Dimensions ANSI B16.15/DIN/JIS//IS Std.

Double Flanged Technical Characteristics

- Body – ductile cast iron EN-GJS-500-7

- According to DIN EN 545 standard

- Epoxy coating RAL5015

- Drilling of flanges: PN10/16, starting from DN200 – PN10

- WRAS approved epoxy coating, ACS approved epoxy coating avalible

Double Flanged Types

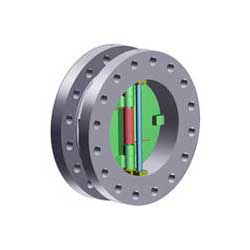

Double Flanged Butterfly Valve

Double Flanged valve with face to face consistent with EN 558-1/20. Suitable for mounting between flanges and might be utilized in many general applications like in water distribution, water treatment, dams, power plants, and in many others. The valve is often used as a stopper, a faucet for discharging at the top of the pipeline, open/close and flow control. The threaded holes make it is easy to put in or uninstall from the pipeline. Operation is often manual, pneumatic, hydraulic or electric.

High Performance Double Flanged End Butterfly Valves, which are available in class 150 / 300/ 600 and PN16 / 25 / 40 / 100 pressure rating. Double Flanged Butterfly Valves connections are often lugged type, wafer type, or double flange type for Customers to decide on from.

Ductile Iron Double Flanged Pipes

Ductile Iron Double Flange Pipes are having flanged at both its end which are connected using Nut Bolts. It’s used for over ground and exposed installations as under Vertical Installations, Over Ground Installations. DI Flange Puddle Pipe also are availables during which the ends are either flanges or plain (spigot) and one flange is welded onto the pipe.

Cast Iron Double Flanged Pipe

We are Manufacturer, Exporter and Supplier of Cast Iron Double Flanged Pipes widely in demand amongst buyers. Made using the best quality material and advanced technology, our CIDF Pipes are appreciated for his or her excellent finish, optimum strength, high corrosion resistance and sturdiness. We make available bulk quantities of CIDF Pipes at the foremost competitive rates. We ensure a timely delivery of the orders.

Double Flanged Bend

Double Flanged Bend that’s utilized in varied industries. Keeping in state of mind industry norms; this bend is intended by our experienced professionals by using supreme quality material and complicated technology. Furthermore, our quality examiners test this bend on predefined parameters to make sure its durability.

Double Flanged Tee

Double Flanged Tee are manufactured at our well established designing unit using the best quality material and innovative technology in a sync with set quality norms. To make sure their durability, these tees are tested against varied quality parameters. Customers can avail these tees from us at budget Best prices.

Double Flanged Dimensions

| Class LA | Pipe Dimensions Class A | Class B | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Nominal Dia. Dn |

Flange Dimensions | Holes | |||||||||||||||||

| C | D | b | a | r | s | A No.of hole | D dia of hole | Dia of bolt | Mass of finge | e | Mass for 1 mtr barrel | Mass for 5.5 barrel with socket | e | Mass for 1 mtr barrel | Mass for 5.5 barrel with socket | e | Mass for 1 mtr barrel | Mass for 5.5 barrel with socket | |

| 80 | 160 | 200 | 21.0 | 42 | 6 | 17 | 4 | 19 | 16 | 4.3 | 7.2 | 14.7 | 64 | 7.9 | 16.0 | 69.5 | 8.6 | 17.3 | 74.5 |

| 100 | 180 | 220 | 22.0 | 44 | 6 | 18 | 8 | 19 | 16 | 5.0 | 7.5 | 18.6 | 109 | 8.3 | 20.5 | 120 | 9.0 | 22.0 | 128 |

| 125 | 210 | 250 | 22.5 | 45 | 6 | 19 | 8 | 19 | 16 | 6.6 | 7.9 | 24.2 | 142 | 8.7 | 26.4 | 155 | 9.5 | 28.7 | 167 |

| 150 | 240 | 285 | 23.0 | 46 | 6 | 20 | 8 | 23 | 20 | 8.2 | 8.3 | 30.1 | 177 | 9.2 | 33.2 | 194 | 10.0 | 35.9 | 209 |

| 200 | 295 | 340 | 24.5 | 49 | 6 | 22 | 8 | 23 | 20 | 11.4 | 9.2 | 44.0 | 259 | 10.0 | 48.1 | 281 | 11.0 | 52.1 | 304 |

| 450 | 570 | 620 | 31.5 | 64 | 8 | 32 | 16 | 28 | 24 | 32.6 | 13.3 | 141.0 | 832 | 14.7 | 156.0 | 914 | 16.0 | 169.0 | 986 |

| 500 | 620 | 670 | 33.0 | 67 | 8 | 34 | 20 | 28 | 24 | 38.1 | 14.2 | 165.2 | 974 | 15.6 | 181.0 | 1061 | 17.0 | 196.7 | 1148 |

| 600 | 725 | 780 | 36.0 | 70 | 8 | 38 | 20 | 31 | 27 | 52.4 | 15.8 | 219.8 | 1298 | 17.4 | 241.4 | 1417 | 19.0 | 262.2 | 1535 |

| 700 | 840 | 895 | 38.5 | 80 | 10 | 41.5 | 24 | 31 | 27 | 72 | 17.5 | 283.2 | 1675 | 19.3 | 311.6 | 1830 | 21.0 | 338.2 | 1977 |

| 250 | 350 | 395 | 26.0 | 52 | 6 | 24 | 12 | 23 | 20 | 14.7 | 10.0 | 59.3 | 349 | 11.0 | 65.0 | 380 | 12.0 | 70.6 | 411 |

| 300 | 400 | 445 | 27.5 | 55 | 6 | 26 | 12 | 23 | 20 | 18.6 | 10.6 | 76.5 | 450 | 11.9 | 84.0 | 492 | 13.0 | 91.4 | 533 |

| 350 | 460 | 505 | 29.0 | 58 | 8 | 28 | 16 | 23 | 20 | 21.2 | 11.7 | 96.3 | 567 | 12.8 | 105.0 | 615 | 14.0 | 114.5 | 667 |

| 900 | 1050 | 1115 | 44.0 | 100 | 12 | 49.5 | 28 | 34 | 30 | 115 | 20.8 | 431.8 | 2558 | 22.9 | 474.3 | 2791 | 25.0 | 516.6 | 3024 |

| 1000 | 1160 | 1230 | 47.0 | 110 | 12 | 52.5 | 28 | 37 | 33 | 145 | 22.5 | 518.3 | 3073 | 24.8 | 570.0 | 3357 | 27.0 | 619.2 | 3628 |

| 400 | 515 | 565 | 30.0 | 61 | 8 | 30 | 16 | 28 | 24 | 27.3 | 12.5 | 116.9 | 690 | 13.8 | 128.7 | 754 | 15.0 | 139.5 | 814 |

| 750 | 900 | 960 | 40.0 | 85 | 10 | 45.5 | 24 | 31 | 27 | 85 | 18.3 | 317.2 | 1876 | 20.2 | 348.9 | 2051 | 22.0 | 380.6 | 2225 |

| 800 | 950 | 1015 | 41.5 | 90 | 12 | 46.5 | 24 | 34 | 30 | 97 | 19.2 | 354.9 | 2100 | 21.1 | 389.1 | 2288 | 23.0 | 423.1 | 2475 |

Double Flanged Materials

Stainless Steel Double Flanged :

- ASTM / ASME A/SA 182: F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L.

Duplex & Super Duplex Steel Double Flanged :

- ASTM / ASME A/SA 182: F44, F45, F51, F53, F55, F60, F61.

Nickel Alloy Double Flanged :

- ASTM / ASME SB 564 / 160 / 472: UNS 2200 (NICKEL 200), UNS 4400 (MONEL 400), UNS 8825 INCONEL (825), UNS 6600(INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276), UNS 2201 (NICKEL 201), (ALLOY 20 / 20 CB 3)

Copper Alloy Double Flanged :

- ASTM / ASME SB 61 / 62 / 151 / 152: UNS NO. C 92200, UNS NO. C 83600, UNS NO. 70600, 71500, C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30), UNS NO C 10100, C 10200, C 10300, C 10800, C 12000, C 12200

Carbon Steel Double Flanged :

- ASTMA 105/A694/ A350 LF3/A350 LF2: F42, F46, F52, F56, F60, F65, F70

Alloy Steel Double Flanged :

- ASTM A182: F1, F5, F9, F11, F22, F91

Brass Forged Steel Double Flanged :

- Brass CA 360, CA 345 and CA 377 / SAE J530, SAE J531 and ASA

Double Flanged Pipe Application Industries

- Refineries

- Food Processing & Dairy

- Oil and Gas Industry

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Power Generation

- Specialty Chemicals

- Sea Water Equipment

- Gas Processing

- Chemical Equipment

- Heat Exchangers

- Petrochemicals

- Pharmaceuticals

- Condensers

Double Flanged Pipe Inspection

The Double Flanged Inspection checked and tested in accordance with applicable ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. The typical applicable codes and standards are ANSI / ASME. our experienced engineer team are ready to solve problem for you and take care of your industry. Our experts support you provide Steel Double Flanged Pipe inspection controls the entire manufacturing process, All Double Flanged production progress are subject to strict in-process inspection at each stage of the Manufacturing process, from starting materials handling to finished products shipping.

Double Flanged Packing & Forwading

The importance of proper packing for piping goods. it is not only protection of products or save cash but also proof of our professionalize. So for various goods, there are different protecting packing methods. For packing of Double Flanged with painting, We might use the bubble wrap to guard the painting. we might suggest client to use the anti-tarnish paper and bag to stop the rust. Each item is packed in poly pouches after multi stage inspections. These mini cartons are sealed and skilled Shrink Wrapping poly bag sealing machine to make sure safety from moisture. Such mini cartons are placed in bituminous hessian cloth 7 poly master carton. The contents of every master carton are shown on the carton. Each master carton is sealed with white printed heat salable strapping.

Double Flanged Pipes Export & Supply to below mentioned Countries

ASIA: Malaysia, India, Taiwan, Cambodia, Singapore, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Myanmar.

SOUTH AMERICA: Venezuela, Argentina, Bolivia, Colombia, Ecuador, Guyana, Paraguay, Uruguay, Brazil, Chile.

AFRICA: South Africa, Nigeria, Algeria, Angola, Libya, Egypt, Gabon, Sudan, Equatorial Guinea, The Republic Of Congo.

NORTH AMERICA: USA, Canada, Mexico, Panama, Costa Rica, Puerto Rica, Trinidad And Tobago, Jamaica, Bahamas, Denmark.

EUROPE: UK, Netherland, Russia, Norway, Germany, France, Italy, Spain, Ukraine, Belgium, Greece, Hungary, Albania, Austria, Finland, Ireland, Croatia, Slovenia, Malta, Switzerland, Slovakia, Czech Republic, Portugal.

Double Flanged Pipe Export & Supply to below Mentioned Cities

Mumbai, Thane, Navi Mumbai, Pune, New Delhi, Bengaluru, Chennai, Surat, New York, Caracas, Howrah, Sydney, Ahvaz, Karachi, Algiers, Pimpri-Chinchwad, Vadodara, Kolkata, Gurgaon, Ahmedabad, Chiyoda, Ankara, Ho Chi Minh City, Bhopal, Dubai, Seoul, Hyderabad, Singapore, Abu Dhabi, Tehran, Calgary, Noida, Riyadh, Vung Tau, Al Khobar, Atyrau, Lagos, Ulsan, Faridabad, Houston, Hanoi, Toronto, Hong Kong, Rajkot, Brisbane, Los Angeles, London, Muscat, Edmonton, Busan, Mexico City, Doha, Jeddah, Manama, Montreal, Thiruvananthapuram, Milan, Moscow, Dallas, Coimbatore, Jakarta, Istanbul, Bangkok, Kuwait City, Sharjah, Petaling Jaya, Ernakulam, Visakhapatnam, Ludhiana, Aberdeen, Cairo, Geoje-si, Perth, Santiago, Chandigarh, Indore, Kuala Lumpur, Rio de Janeiro, Dammam, Secunderabad, Gimhae-si, Haryana, Colombo, Lahore, Bogota, Melbourne, Madrid, La Victoria, Granada, Courbevoie, Al Jubail, Port-of-Spain.