Stainless Steel 446 Forged Fittings Manufacturer, SS 446 Socket Weld Fittings, SS 446 Threaded Fittings

ISO Certified Suppliers and Exporters of ASTM A182 Stainless Steel 446 Forged Fittings, Stainless Steel 446 Threaded Fittings, Stainless Steel 446 Socket weld Fittings, ASME SA182 SS 446 Forged Threaded Fittings, UNS S44600 Forged Fittings, WNR 1.4762 Forged Pipe Fittings, ASME SA182 SS 446 Socket weld Fittings, A182 gr F446 Forged Elbow in India.

- 446 SS Forged Fittings Specifications

- SS 446 Forged Fittings Dimensions

- 446 SS Socket weld Fittings Types

- 446 SS Threaded Fittings Types

- Equivalent Grades of SS 446 Forged Fittings

- Chemical Composition of SS 446 High Pressure Forged Fittings

- Mechanical Properties of SS A182 446 Forged Fittings

- Manufacturing Standards of SS 446 Forged Fittings

- 446 SS Forged Fittings Standard

- Ready Stock of SS 446 Forged Pipe Fittings

- SS 446 Threaded Fittings Application

- 446 SS Socket Weld Fittings Quality Check

- SS 446 Forged Fittings Packing & Forwarding

446 Stainless Steel Forged Threaded Fittings Price

+91 90793 67689

sales@creativepiping.com

Largest stockists of Wrought Austenitic Stainless Steel 446 Forged Elbow, Werkstoff No 1.4762 Threaded Pipe Bends, AISI SS 446 Socet Weld Tee, INOX 1.4762 Threaded Stub End, ANSI B16.9 SS 446 Threaded End Cap, SUS 446 Forged Reducer, DIN 1.4762 Socket weld Cross, ASME SA182M SS 446 Socket weld Couplings.

Creative Piping Solutions is the reliable Manufacturer, Exporter, and Supplier of the great quality ASTM A182 SS 446 Forged Fittings. It’s fabricated by using excellent quality material. The offered product range is supplied during a comprehensive range in order that all application demands are often very well satisfied. The SS F410 Forged Fittings are highly appreciated due to various good attributes. The utilization of advanced tools, and the latest technology in the right way is assuring producers in bringing out the exemplary quality of the product.

Stainless steel 446, is a high chromium ferric heat-resistant alloy that’s having high oxidation resistance, suffixation, and hot corrosion resistance ability. This alloy is usually used between temperatures starting from 1500 Deg F to 2100 Deg F, although the elevated temperature strength is lower. 446 SS alloy is a heat-resistant alloy that tolerates molten brass and copper.

Alloy 446 should be used at this temperature unless full temperature ductility loss can be tolerated. Sigma phase embitterment might occur upon exposure within the temperature ranging from 100 Deg F to 1300 Deg F. stainless-steel 446 alloy is very ductile to the brittle impact transition temperature. The successful forming and bending by the sting preparation, low forming speed, and preheating at temperatures of 250 Deg F to 400 Deg F are often aided. Annealing when needed, is often done at a temperature starting from 1550 to 1650 Deg F, followed by fast cooling. Welding is often done through the traditional methods and post-heating and preheating to the temperature of 300 deg f to 600 deg f is useful.

446 Stainless Steel Forged Fittings Specifications

- Forged Type Socket Weld Pipe Fittings

- Socket Weld Size 1/8″~4″ (DN6~DN100)

- Socket Weld Pressure Class 2000LBS, 3000LBS, 6000LBS, 9000LBS

- Socket Weld Dimension ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

- Socket Weld Form 90° Elbow, 45° Elbow, Tee, Cross, Full Coupling, Half Coupling, 90° Elbow Outlet, 45° Lateral Tee, Lateral Outlet, Pipe Cap, Union, Reducer Insert, Boss, Branch Outlet,

- Forged Type Threaded / Screwed Pipe Fittings

- Threaded Size 1/8″~4″ (DN6~DN100)

- Threaded Pressure Class 2000LBS,3000LBS, 6000LBS, 9000LBS

- Threaded Dimension ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

- Threads ISO, DIN, NPT, BSPT

- Threaded Forms 90° Elbow, 45° Elbow, Tee, Cross, Full Coupling, Half Coupling, Reducing Coupling, Street Elbow, Bull Plug, Boss, Swage Nipple, Pipe Nipple, Adapter, Pipe Cap, Round Head Plug, Hex Head Bushing, Hex Head Plug, Union (Male x Female), Lateral Outlet, Branch Outlet, 90° Elbow Outlet, 45° Lateral Tee, Square Head Plug, Union, Hex Nipple, Nipple Branch Outlet

Stainless Steel 446 Forged Fittings Dimensions

446 Stainless Steel Socket weld Fittings Types

446 Stainless Steel Threaded Fittings Types

Equivalent Grades of Stainless Steel 446 Forged Fittings

| STANDARD | UNS | WERKSTOFF NR. | JIS | AFNOR | BS | GOST | EN |

|---|---|---|---|---|---|---|---|

| SS 446 | S44600 | 1.4762 / 3 | – | – | – | – | – |

Chemical Composition of Stainless Steel 446 High Pressure Forged Fittings

| Grade | C | Mn | P | S | Si | Cr | MO | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| 446 | Min | – | – | – | – | – | 23.00 | – | – | 0.10 |

| max | 0.2 | 1.5 | 0.75 | 0.030 | 30.00 | 0.040 | – | 0.50 | 0.25 | – |

Mechanical Properties of Stainless Steel A182 446 Forged Fittings

| Grade | Density | Tensile Strength | Melting Point | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| 446 | 7.5 g/cm3 | Psi – 75,000 , MPa – 485 | 1510 °C (2750 °F) | Psi – 40,000 , MPa – 275 | 20 % |

Manufacturing Standards of Stainless Steel 446 Forged Fittings

| ASTM A182 / A182M | Forged Fittings and valves and parts for high temperature service. Standard Specification for Wrought Austenitic Stainless Steel Forged Fittings |

| ANSI B16.11 | Forged steel fittings socket-welding and threaded. Socket Welding and Threaded Forged Fittings |

| ANSI/ASME B1.20.1 | Pipe threads, general purpose (inch). |

| BS21 | Threading. |

| BS3799 | Specification for Steel pipe fittings, screwed and Socket-welding for the petroleum industry |

| ISO 4144 | Stainless steel fittings threaded to ISO 7-1. |

| MSS SP-95 | Swage(d) Nipples and Bull Plugs |

446 Stainless Steel Forged Fittings Standard

| American Steel Forged Fittings Standard | |

| Standard Code | Standard Name |

| ANSI ASME B16.11 | Socket-welding and Threaded forged fittings |

| ANSI ASME SA-182 | Forged fittings |

| MSS SP-95 | Swaged nipples and round plugs |

| MSS SP-79 | Socket-welding reducing Inserts |

| MSS SP-83 | Class 3000 steel socket-welding and threaded unions |

| MSS SP-97 | SW,TH and BW ends for integrally reinforced forged branch outlet |

Ready Stock of Stainless Steel 446 Forged Pipe Fittings

| Stainless Steel 446 Socket Weld 45 Deg Elbow | SS Grade F446 90 Degree BSP Threaded Elbow |

| Stainless Steel 446 Socket Weld Tee | UNS S44600 High Pressure Forged Fittings |

| SS Grade F446 Socket Weld Reducing Tee | Stainless Steel 446 Forged Equal Cross 3000lb |

| ASTM A182 F446 Socket Weld Coupling | ASTM A182 F446 Stainless Steel Full Coupling |

| Stainless Steel 446 Full Coupling | UNS S44600 Socket Weld Pipe Cap |

| ASTM A182 F446 NPT Threaded Pipe Cap | Stainless Steel 446 Forged Union 3000LB |

| SS 446 Forged Screwed Union | SS 446 Forged Socket weld Fittings |

| 446 SS 3000 LB Threaded Fittings | UNS S44600 NPT Threaded Fittings |

| 446 SS 3000 LB Threaded Elbow Class 150 | UNS S44600 NPT Threaded Tee |

| ASTM A182 F446 90 degree Threaded Elbow | INXO 1.4762 Forged Reducing Tee |

| ANSI B16.11 F446 Threaded Cross | Stainless Steel 446 Threaded Full Coupling |

| 446 Stainless Steel NPT Threaded Plug | SS 446 3000LB Threaded End Pipe Cap |

| Stainless Steel 446 Forged Threaded Bushing | ASTM A182 F446 Stainless Steel Screwed Union |

| SS 446 Forged Threaded Swage Nipple | SS Grade F446 Screwed Forged Plug |

| 1.4762 SS Forged Threaded Hex Nipple | Stainless Steel 446 Threaded Hex Plug |

| ASME B16.11 Stainless Steel 446 Threaded Swage Nipple | 446 Stainless Steel Threaded Pipe Nipples |

| SS 446 NPT Threaded Street Elbow | Stainless Steel F446 Threaded Adapter |

| 446 Stainless Steel Threaded Union BS 3799 | Stainless Steel 446 Forged Eccentric Swage Nipple |

| 446 SS 3000 LB 1/2 Threaded Half Coupling | Stainless Steel 446 BSP Swage Nipple |

| ASTM A182 F446 Threaded Pipe Half Coupling | Stainless Steel F446 Screwed Street Elbow |

| ASTM A182 F446 Forged Socket weld Pipe Cap | Stainless Steel SUS 446 Forged Socket weld Boss |

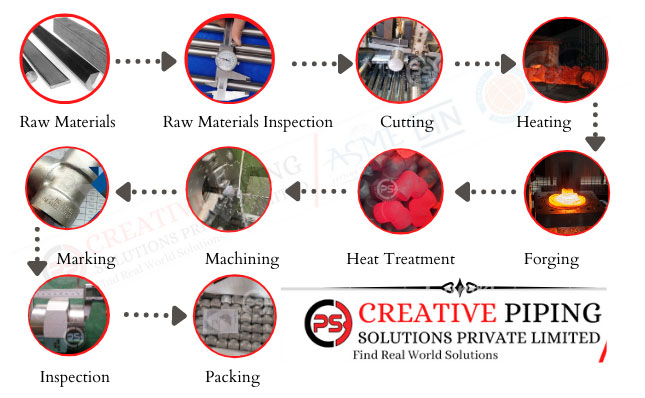

Stainless Steel 446 Threaded Fittings Manufacturing Process

Stainless Steel 446 Threaded Fittings Application Industries

We produce full range of Stainless Steel 446 Forged Threaded Fittings in every sizes, pressure / classes, dimensions to meet needs of customers. Our products are well accepted by the majority of customers. it’s widely used in aerospace, shipbuilding, metallurgy, automotive instrumentation, petrochemical, food machinery, biological engineering In the field of environmental protection.

- Refineries

- Food Processing & Dairy

- Oil and Gas Industry

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Power Generation

- Specialty Chemicals

- Sea Water Equipment

- Gas Processing

- Chemical Equipment

- Heat Exchangers

- Petrochemicals

- Pharmaceuticals

- Condensers

446 Stainless Steel Socket Weld Fittings Inspection

We at Creative Piping Solutions ensures that all our materials go through strict quality tests before dispatching them to our clients. we conduct all necessary test of SS 446 Threaded Fittings to assure the quality of deliver products to fit clients projects and needs. NDT test used for SS 446 Socket weld Fittings are Positive material identification (PMI), Penetrating liquids, Ferrite content, Hydrostatic test / hydro testing (pressure testing), Magnetic particles, Macrography, Micrography, Pneumatic pressure, Radiography. All of the listed test, the pressure testing is one of the most commonly specified, especially for mission critical fittings in the pipeline.

Stainless Steel 446 Forged Fittings Packing & Forwarding

There are different ways of packing a 446 SS Forged Fittings, but two principles that are vital for any method to work prevent rusting and Sea transportation security. Our all products packed with seaworthy packing method then delivery to customers, usually the packing way include wooden box, wooden pallet. We make sure that it is seaworthy, strong, waterproof and easy for loading and unloading. All shipping and product details also stick to outside of package. 446 SS Threaded Fittings pack with environmental poly bags, and then in free fumigation wooden cases or wooden plate. 446 SS Socket Weld Fittings are packed in wooden corrugated boxes foiled in bubble wraps and plastic wraps.

ASTM A182 SS 446 Threaded Fittings Export & Supply to below mentioned Countries

ASIA: Malaysia, India, Taiwan, Cambodia, Singapore, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Myanmar.

SOUTH AMERICA: Venezuela, Argentina, Bolivia, Colombia, Ecuador, Guyana, Paraguay, Uruguay, Brazil, Chile.

AFRICA: South Africa, Nigeria, Algeria, Angola, Libya, Egypt, Gabon, Sudan, Equatorial Guinea, The Republic Of Congo.

NORTH AMERICA: USA, Canada, Mexico, Panama, Costa Rica, Puerto Rico, Trinidad, And Tobago, Jamaica, Bahamas, Denmark.

EUROPE: UK, Netherlands, Russia, Norway, Germany, France, Italy, Spain, Ukraine, Belgium, Greece, Hungary, Albania, Austria, Finland, Ireland, Croatia, Slovenia, Malta, Switzerland, Slovakia, Czech Republic, Portugal.