ASME B16.47 / ANSI / ASME B16.5 Reducing Flange Manufacturer

ASME B16.47 Reducing Flange Suppliers, Series A, and Series B Reducing Flange, BS10 Reducing Flange, AWWA C207 Reducing Flange, EN 1092-1 Reducing Flange Price List. ANSI B16.5 Class 150, Class 300, Class 600, Class 900, Class 1500, Class 2500 Reducing Flanges Manufacturer in India

Stockists of Reducing Flange in Duplex Steel, Super Duplex Steel, Stainless Steel, Nickel Alloy, Inconel, Hastelloy, Monel, Titaniun, Incoloy, Copper Nickel, Aluminium, Bronze, Alloy 20, 254 SMO, Mild Steel, Carbon Steel, Alloy Steel, Brass. Reducing Flange Exporters & Suppliers in South Africa, Malaysia, Singapore, UK, Philippines, Australia and Dubai, UAE.

Creative Piping Solutions is a Manufacturer, Supplier, and Exporter of top quality Reducing Flanges. Reducing Flanges connect two different diameter pipes. Reducing Flanges are often wont to conserve water, they’re immune to acid and corrosion, and are commonly utilized in power plants and on industrial vessels due to their significant advantages. These are available in various pressure classes and are widely used for pipe-to-pipe connections. These Reducing Flanges also offer a range of advantages like reliability, close tolerances, and durability.

Reducing Flange is a specialty flange that’s most frequently used on projects that need the fitting together of various sized pipes. There are several sorts of reducing flanges including weld-neck reducing flange, slip-on reducing flange, and threaded reducing flange.

Reducing Flanges can be grouped into 3 main configuration– Type 1, 2 & 3

- A Type 1 Reducing Flange – where the reduction in bores is sort of small the bolt holes need to be staggered on/off centers in order that they don’t clash.

- A Type 2 Reducing Flange – Where the reduction isn’t so great and therefore the periphery of the smaller bore mating flange would hit the nuts then these sorts of flanges are employed with threaded bolt holes negating the utilization of nuts.

- A Type 3 Reducing Flange – flanges have through holes for the big bore bolts and are used where there’s a big reduction in bores.

ANSI / ASME B16.5 Reducing Flange Specifications

- Flange Size ½” (15 NB) to 48″ (1200NB)

- Flange Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40.

- Flange DIN DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

- Flange BS BS4504 , BS4504, BS1560, BS10

- Flange Standard ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48, BS 4504, EN1092, UNI 2277/2278, DIN, JIS, SABS1123, GOST-12820

- Flange Coating/Surface Treatment Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized

- Flange Connection Type Ring Type Joint, Lap-Joint Face, Raised Face, Flat Face, Large Male-Female, Small Male-Female, Large, Tongue & Groove, Small Tongue & Groove

- Flange Face Type Flat Face (FF), Raise Face (RF), Ring Joint (RJT)

- Flange Dimensions ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

- Flange JIS 5K, 10K, 16K, 20K, 30K, 40K, 63K

- Flange UNI 6Bar 10Bar 16Bar 25Bar 40Bar

- Flange Coating Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized

- Production technique Forged, Heat treated and machined

- Test Certificates EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report, etc

- Flange Test Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector

- Equipment Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc

- Flange Origin Indian / West Europe / Japan / USA / Korean

Reducing Flanges Class 150 Dimensions

Dimensions do not include .25″ (6.4 mm) raised face. Class 2500 (PN 420) Socket Welding and Slip-on Flanges not covered by ANSI B16.5

| NPS | DIAMETER | THICKNESS | DIA. | WELDING | MIN. | MIN. | MIN. | NECK | WELDING | JOINT | ||||

| DN | O | T | A | B | C | D | E | F | G | H | ||||

| 1/2 | 5.25 | 1.19 | 1.38 | 0.88 | .90 | 0.93 | 2.88 | 1.56 | 1.56 | |||||

| 15 | 133 | 30.5 | 34.9 | 22.2 | 22.9 | 23.5 | 73.0 | 40 | 40 | |||||

| 3/4 | 5.50 | 1.25 | 1.69 | 1.09 | 1.11 | 1.14 | 3.12 | 1.69 | 1.69 | |||||

| 20 | 140 | 32.0 | 42.9 | 27.8 | 28.2 | 29.0 | 79.4 | 43 | 43 | |||||

| 1 | 6.25 | 1.38 | 2.00 | 1.36 | 1.38 | 1.41 | 3.50 | 1.88 | 1.88 | |||||

| 25 | 159 | 35.0 | 50.8 | 34.5 | 34.9 | 36.0 | 88.9 | 48 | 48 | |||||

| 1 1/4 | 7.25 | 1.50 | 2.50 | 1.70 | 1.72 | 1.75 | 3.75 | 2.06 | 2.06 | |||||

| 32 | 184 | 38.5 | 63.5 | 43.3 | 43.7 | 44.5 | 95.2 | 52 | 52 | |||||

| 1 1/2 | 8.00 | 1.75 | 2.88 | 1.95 | 1.97 | 1.99 | 4.38 | 2.38 | 2.38 | |||||

| 40 | 203 | 44.5 | 73.0 | 49.6 | 50.0 | 50.5 | 111.4 | 60 | 60 | |||||

| 2 | 9.25 | 2.00 | 3.62 | To be | 2.44 | 2.46 | 2.50 | 5.00 | 2.75 | 2.75 | ||||

| 50 | 235 | 51.0 | 92.1 | 61.9 | 62.5 | 63.5 | 127.0 | 70 | 70 | |||||

| 2 1/2 | 10.50 | 2.25 | 4.12 | specified | 2.94 | 2.97 | 3.00 | 5.62 | 3.12 | 3.12 | ||||

| 65 | 267 | 57.5 | 104.8 | 74.6 | 75.4 | 76 | 142.9 | 79 | 79 | |||||

| 3 | 12.00 | 2.62 | 5.00 | by | 3.57 | 3.60 | 3.63 | 6.62 | 3.62 | 3.62 | ||||

| 80 | 305 | 67.0 | 127.0 | 90.7 | 91.4 | 92 | 168.2 | 92 | 92 | |||||

| 4 | 14.00 | 3.00 | 6.19 | purchaser | 4.57 | 4.60 | 4.63 | 7.50 | 4.25 | 4.25 | ||||

| 100 | 356 | 76.5 | 157.2 | 116.1 | 116.8 | 118 | 190.5 | 108 | 108 | |||||

| 5 | 16.50 | 3.62 | 7.31 | 5.66 | 5.69 | 5.69 | 9.00 | 5.12 | 5.12 | |||||

| 125 | 419 | 92.5 | 185.7 | 143.7 | 144.5 | 145 | 228.6 | 130 | 130 | |||||

| 6 | 19.00 | 4.25 | 8.50 | 6.72 | 6.75 | 6.75 | 10.75 | 6.0 | 6.0 | |||||

| 150 | 483 | 108.0 | 215.9 | 170.7 | 171.4 | 171 | 273.0 | 152 | 152 | |||||

| 8 | 21.75 | 5.00 | 10.62 | 8.72 | 8.75 | 8.75 | 12.50 | 7.0 | 7.0 | |||||

| 200 | 552 | 127.0 | 269.9 | 221.5 | 222.2 | 222 | 317.5 | 178 | 178 | |||||

| 10 | 26.50 | 6.50 | 12.75 | 10.88 | 10.92 | 10.88 | 16.50 | 9.0 | 9.0 | |||||

| 250 | 675 | 165.5 | 323.8 | 276.2 | 277.4 | 276 | 419.4 | 229 | 229 | |||||

| 12 | 30.00 | 7.25 | 15.00 | 12.88 | 12.92 | 12.94 | 18.25 | 10.0 | 10.0 | |||||

| 300 | 760 | 184.5 | 381.0 | 327.0 | 328.2 | 329 | 463.6 | 254 | 254 | |||||

Why Creative Piping Solutions

- Quality Products:

- Raw Materials are adeuately tested

- Conformaity to ASTM, ASME, DIN, EN, JIS.

- Marking, Heat Number. Specificatios

- 100% Radiography Test Report

- Third Party Inspection, Buyer Inspection

- Value Added Services:

- Epoxy & fbe coating

- Hot dipped galvanizing.

- Sand blasting

- Electro polish or other special finishes

- Custom shape cutting, fabrication services

- Threading, soldering

- Manufacturing Expertise:

- Custom size flanges

- High quality Industrial Flanges manufacturer.

- Accurate dimensions

- Products with unifrom wall thickness

- We use top quality raw materials

- Over 10 years of manufacturing experience

Reducing Flanges Materials

Most common materials used in the production of Reducing Flanges are Carbon Steel, Stainless Steel, Duplex Steel, Nickel Alloys. Complete list of grades, materials, and manufacturing standards are given below.

Carbon Steel Reducing Flanges:

- High Temperature Carbon Steel ASTM A105: A53, A106, API 5L

- Low Temperature Carbon Steel ASTM A350: LF1, LF2, LF3

- High Yield Carbon Steel ASTM A694: F42, F52, F60, F65

Alloy Steel Reducing Flanges:

- Alloy Steel ASTM A182: F5, F9, F11, F22, F1, F5/F5a, F91

Stainless Steel Reducing Flanges:

- Stainless Steel ASTM A182: F304, F304H, F304L, F304N, F304LN, F309H, F310, F310H, F310MoLN, F316, F316H, F316L, F316N, F316LN, F316Ti, F317, F317L, F321, F321H, F347, F347H, F348, F348H, 904L

Duplex Steel Reducing Flanges:

- Duplex Steel ASTM A182: Duplex 2205 (UNS S31803 – UNS S32205)

- Super Duplex ASTM A182: UNS S32750 – UNS S32760

Nickel Alloy Reducing Flanges:

- ASTM B160: Nickel 200 Flange | Nickel 201

- ASTM B166: Inconel 600 Flange

- ASTM B564: Inconel 625 Flange

- ASTM B425: Incoloy 800 Flange

- ASTM B564: Incoloy 825 Flange

- ASTM B564: Monel K400 Flange | Monel 400

- ASTM B564: Hastelloy C276 Flange | Hastelloy B, Hastelloy D, Hastelloy C-276, Hastelloy G

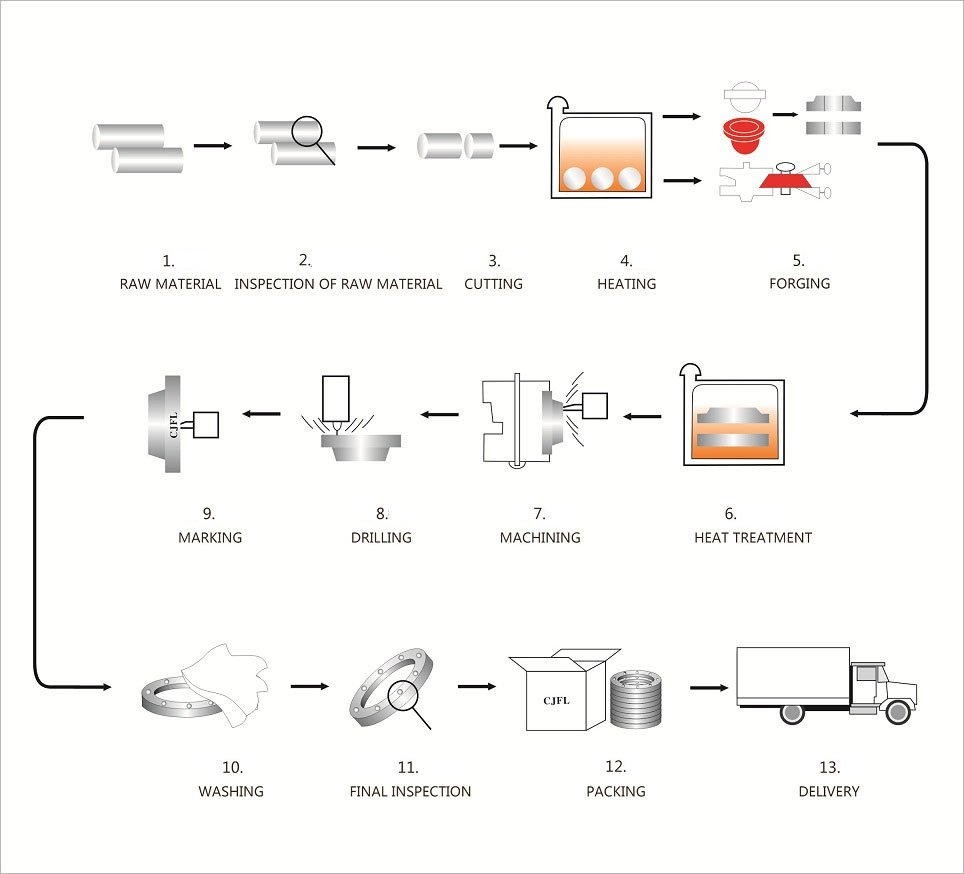

ANSI B16.5 Reducing Flanges Manufacturing Process

ASME B16.47 Reducing Flanges Application Industries

- Refineries

- Food Processing & Dairy

- Oil and Gas Industry

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Power Generation

- Specialty Chemicals

- Sea Water Equipment

- Gas Processing

- Chemical Equipment

- Heat Exchangers

- Petrochemicals

- Pharmaceuticals

- Condensers

ASME B16.47 / ANSI B16.5 Reducing Flanges Inspection

Our qualified inspection engineer performed inspection on Reducing Flanges based on reference standards of ASME B31.1, B31.3, B16.5, ASME II , V , VIII , IX , DIN, AS/NZ standards etc. A visual test performed to identify surface porosity, cracks, and open structure defects. A dimensional inspection performed to confirm that the different types of flange, in this case its Reducing Flange, Raised Face Reducing Flange, Flat Face Reducing Flange, etc. are manufactured according to the ASME Specification, that specifies the dimensions and indicates the design tolerances. A tensile test is conducted to test the yield strength, the tensile strength, and the elongation restrictions. A hardness test is conducted to check micro-hardness and surface hardness to confirm the acid environment performance and material performance. Magnetic particle inspection is performed to detect locating surface and near subsurface discontinuities in ferromagnetic materials, if some surface cracks, folds, thrust fault, pit or gas hole.

ANSI B16.5 Reducing Flanges Packing & Forwarding

We follow the packing procedure of Reducing Flanges to insure damage free delivery of BS10 Reducing Flange to our valuable customers in India and overseas. usually the packing way include wooden pallet, wooden box, iron & steel pallet, iron & steel cage etc. Because of the normal wooden pallets or wooden boxes have to do fumigation treatment, we choose plywood box or case or plywood pallet to pack Series A and Series B Reducing Flange without fumigation treatment. Whatever plywood or iron & steel packing way, we make sure that it must be strong, seaworthy, waterproof. All details of ASME B16.5 Reducing Flange are also stick with flanges packing so that it can be easy to understand and we insure that packing can ease the process of loading and unloading of goods.

ASME B16.5 Reducing Flanges Export & Supply to below mentioned Countries

ASIA: Malaysia, India, Taiwan, Cambodia, Singapore, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Myanmar.

SOUTH AMERICA: Venezuela, Argentina, Bolivia, Colombia, Ecuador, Guyana, Paraguay, Uruguay, Brazil, Chile.

AFRICA: South Africa, Nigeria, Algeria, Angola, Libya, Egypt, Gabon, Sudan, Equatorial Guinea, The Republic Of Congo.

NORTH AMERICA: USA, Canada, Mexico, Panama, Costa Rica, Puerto Rico, Trinidad And Tobago, Jamaica, Bahamas, Denmark.

EUROPE: UK, Netherlands, Russia, Norway, Germany, France, Italy, Spain, Ukraine, Belgium, Greece, Hungary, Albania, Austria, Finland, Ireland, Croatia, Slovenia, Malta, Switzerland, Slovakia, Czech Republic, Portugal.