Stub End Manufacturer, ASME B16.9 Buttweld Stub End Suppliers

Check Lap Joint Stub Ends Dimensions & Price List, Long Stub End Manufacturer in India

Buttweld Stub End Pipe Fitting, Short Stub End Exporters in India, Stub Ends Suppliers in South Africa, UK, Australia, Singapore, Philippines, and Malaysia.

Creative Piping Solutions are a leading Manufacturer, Exporter, and Supplier of Stub Ends. We provide our materials with complete certifications, and as per international standards. Our production range includes chrome steel Stub Ends, carbon steel Stub Ends, alloy steel Stub Ends in special alloys like Monel, Inconel, Hastelloy. We will manufacture Stub Ends up to 48″ with wall thickness starting from 1.5 mm thickness up to 40 mm for various sizes. We are Manufacturers, Stockist & Suppliers of Stub End. Stub End has special quality finishing and duress for long life, high and 0 defects.

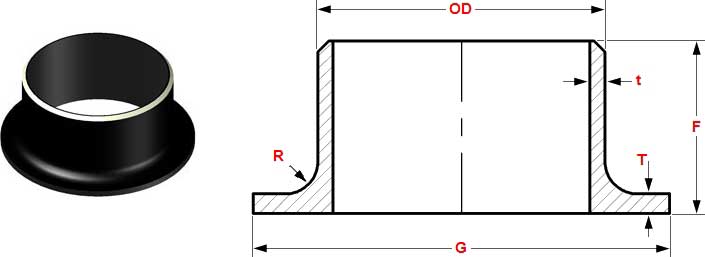

Stub Ends are mechanical joints that consist of two components. The Stub End which essentially a brief length of pipes, which has one end that’s flared outward and therefore, the other end prepared to be welded to the pipe of an equivalent Nominal Pipe Size (NPS), material, and of an identical wall thickness.

Stub ends are butt weld fittings which will be used alternatively to welding neck flanges to form flange connection. The utilization of stub ends has two advantages: it can reduce the entire cost of flange joints for piping systems in high material grades, it accelerates the installation process because the lap joint flange is rotated to facilitate the alignment of the bolt holes. Stub ends are available briefly and in long patterns (ASA and MSS stub ends), in sizes up to 80 inches.

Stub End Specifications

- Size 1/8″NB TO 48″NB IN

- Schedules SCH5, SCH10, SCH40, SCH STD, SCH 80, SCH 100, SCH 120, SCH 160, SCH XS, SCH XXS

- Dimensions ASME/ANSI B16.9, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313, ASME B16.28

- Forms Long Stub End, Short Stub End, Lap Joint stub end

- Type Seamless / ERW / Welded / Fabricated

- Product’s Angle Bevelled

ANSI B16.9 Stub End Types

ASME B16.9 Stub End Dimensions

| NPS | Outside diameter of barrel |

Length (F) | Diameter (G) | Radius (R) | ||

|---|---|---|---|---|---|---|

| Minimum | Maximum | Long Pattern |

Short Pattern |

|||

| 1/2″ | 20.5 | 22.8 | 76 | 51 | 35 | 3 |

| 3/4″ | 25.9 | 28.1 | 76 | 51 | 43 | 3 |

| 2 1/2″ | 72.2 | 75.3 | 152 | 64 | 105 | 8 |

| 3″ | 88.1 | 91.3 | 152 | 64 | 127 | 10 |

| 3 1/2″ | 100.8 | 104.0 | 152 | 76 | 140 | 10 |

| 4″ | 113.5 | 116.7 | 152 | 76 | 157 | 11 |

| 5″ | 140.5 | 144.3 | 203 | 76 | 186 | 11 |

| 6″ | 167.5 | 171.3 | 203 | 89 | 216 | 13 |

| 8″ | 218.3 | 222.1 | 203 | 102 | 270 | 13 |

| 1″ | 32.6 | 35.0 | 102 | 51 | 51 | 3 |

| 1 1/4″ | 41.4 | 43.6 | 102 | 51 | 64 | 5 |

| 1 1/2″ | 47.5 | 49.9 | 102 | 51 | 74 | 6 |

| 2″ | 59.5 | 62.4 | 152 | 64 | 92 | 8 |

| 10″ | 272.3 | 277.2 | 254 | 127 | 324 | 13 |

| 12″ | 323.1 | 328.0 | 254 | 152 | 381 | 13 |

| 14″ | 354.8 | 359.9 | 305 | 152 | 413 | 13 |

| 16″ | 405.6 | 411.0 | 305 | 152 | 470 | 13 |

| 18″ | 456.0 | 462.0 | 305 | 152 | 533 | 13 |

| 20″ | 507.0 | 514.0 | 305 | 152 | 584 | 13 |

| 22″ | 558.0 | 565.0 | 305 | 152 | 641 | 13 |

| 24″ | 609.0 | 616.0 | 305 | 152 | 692 | 13 |

Dimensions of Stub Ends Schedule 10S MSS SP-43 type A/B

| NPS | OD | G | T | F | R Type A |

R Type B |

|---|---|---|---|---|---|---|

| 1/2 | 21.3 | 34.9 | 2.11 | 50.8 | 3.05 | 0.76 |

| 3/4 | 26.7 | 42.9 | 2.11 | 50.8 | 3.05 | 0.76 |

| 2 | 60.3 | 92.1 | 2.77 | 63.5 | 7.87 | 0.76 |

| 2½ | 73 | 104.8 | 3.05 | 63.5 | 7.87 | 0.76 |

| 3 | 88.9 | 127 | 3.05 | 63.5 | 9.65 | 0.76 |

| 1 | 33.4 | 50.8 | 2.77 | 50.8 | 3.05 | 0.76 |

| 1¼ | 42.2 | 63.5 | 2.77 | 50.8 | 4.83 | 0.76 |

| 1½ | 48.3 | 73 | 2.77 | 50.8 | 6.35 | 0.76 |

| 3½ | 101.6 | 139.7 | 3.05 | 76.2 | 9.65 | 0.76 |

| NPS | OD | F | T | G | R Type A |

R Type B |

|---|---|---|---|---|---|---|

| 4 | 114.3 | 76.2 | 3.05 | 157.2 | 11.18 | 0.76 |

| 5 | 141.3 | 76.2 | 3.40 | 185.7 | 11.18 | 1.52 |

| 12 | 323.9 | 152.4 | 4.57 | 381 | 12.7 | 1.52 |

| 14 | 355.6 | 152.4 | 4.78 | 412.8 | 12.70 | 1.52 |

| 16 | 406.4 | 152.4 | 4.78 | 469.9 | 12.7 | 1.52 |

| 6 | 168.3 | 88.9 | 3.40 | 215.9 | 12.7 | 1.52 |

| 8 | 219.1 | 101.6 | 3.76 | 269.9 | 12.7 | 1.52 |

| 10 | 273.1 | 127 | 4.19 | 323.9 | 12.7 | 1.52 |

| 18 | 457.2 | 152.4 | 4.78 | 533.4 | 12.70 | 1.52 |

| 20 | 508 | 152.4 | 5.54 | 584.2 | 12.70 | 1.52 |

| 24 | 609.6 | 152.4 | 6.35 | 692.2 | 12.7 | 1.52 |

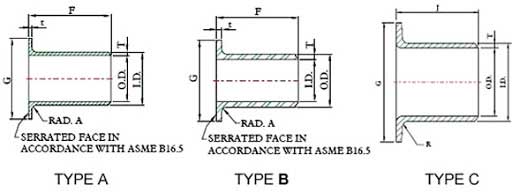

Stub End Types

Type A :

- The Type A Stub End is used for the normal joint flange. The lap thickness on the Stub end is greater than or up to the thickness of the pipe wall. Additionally, the outer corner radius of type A will receive the lap joint flange. The within the corner is square. Lap sometimes includes a machined rough face.

Type B

- The Type B Stub End is used for normal slip-on flanges as lap flanges. The lap thickness on these short ends is greater than or up to the nominal thickness of the pipe wall. Also, the outer corner radius of B is small enough to receive the slip o flange which can be used as a backup flange. The inner corner is square. Lap sometimes includes a machined rough face.

Type C

- The Type C Stub End is going to be used for normal lap joint flange and placed on the flange. If necessary, the radius is going to be created close to a square. The lap joint Stub End thickness is 75th of the pipe wall. The type C is extremely short enough to accommodate any back up flange. The lap joint Stub End on kind C is smooth, and it’s not machined.

Stub End Materials

Stainless Steel Stub End :

- ASTM / ASME A/SA 182: F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L.

Duplex & Super Duplex Steel Stub End:

- ASTM / ASME A/SA 182: F44, F45, F51, F53, F55, F60, F61.

Nickel Alloy Stub End :

- ASTM / ASME SB 564 / 160 / 472: UNS 2200 (NICKEL 200), UNS 4400 (MONEL 400), UNS 8825 INCONEL (825), UNS 6600(INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276), UNS 2201 (NICKEL 201), (ALLOY 20 / 20 CB 3)

Copper Alloy Stub End :

- ASTM / ASME SB 61 / 62 / 151 / 152: UNS NO. C 92200, UNS NO. C 83600, UNS NO. 70600, 71500, C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30), UNS NO C 10100, C 10200, C 10300, C 10800, C 12000, C 12200

Carbon Steel Stub End :

- ASTMA 105/A694/ A350 LF3/A350 LF2: F42, F46, F52, F56, F60, F65, F70

Alloy Steel Stub End :

- ASTM A182: F1, F5, F9, F11, F22, F91

Short / Long Pattern Stub Ends (ASA/MSS)

Stub Ends are available in two different patterns:

- the Short Pattern, called MSS-A Stub Ends

- the Long Pattern, called ASA-A Stub Ends (or ANSI length Stub End)

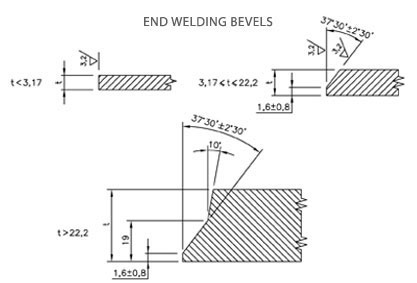

End welding bevels of Stub Ends

| NOMINAL PIPE SIZE (INCHES) | NB | OD | THICKNESS | SCH 10 | SCH 40 | SCH 20 | SCH 30 | SCH 80 |

|---|---|---|---|---|---|---|---|---|

| 1/2 | 15NB | 21.30 | 1.65 | 2.11 | 2.77 | __ | 2.41 | 3.73 |

| 3/4 | 20NB | 26.70 | 1.65 | 2.11 | 2.87 | __ | 2.41 | 3.91 |

| 1 | 25NB | 33.40 | 1.65 | 2.77 | 3.38 | __ | 2.90 | 4.55 |

| 1 1/4 | 32NB | 42.20 | 1.65 | 2.77 | 3.56 | __ | 2.97 | 4.85 |

| 1 1/2 | 40NB | 48.30 | 1.65 | 2.77 | 3.68 | __ | 3.18 | 5.08 |

| 2 | 50NB | 60.30 | 1.65 | 2.77 | 3.91 | __ | 3.18 | 5.54 |

| 2 1/2 | 65NB | 73.00 | 2.11 | 3.05 | 5.16 | __ | 4.78 | 7.01 |

| 3 | 80NB | 88.90 | 2.11 | 3.05 | 5.49 | __ | 4.78 | 7.62 |

| 3 1/2 | 90NB | 101.60 | 2.11 | 3.05 | 5.74 | __ | 4.78 | 8.08 |

| 4 | 100NB | 114.30 | 2.11 | 3.05 | 6.02 | __ | 4.78 | 8.56 |

| 5 | 125NB | 141.30 | 2.77 | 3.40 | 6.55 | __ | __ | 9.53 |

| 6 | 150NB | 168.30 | 2.77 | 3.40 | 7.11 | __ | __ | 10.97 |

| 8 | 200NB | 219.10 | 2.77 | 3.76 | 8.18 | 6.35 | 7.04 | 12.70 |

| 10 | 250NB | 273.00 | 3.40 | 4.19 | 9.27 | 6.35 | 7.80 | 15.09 |

| 12 | 300NB | 323.80 | 3.96 | 4.57 | 10.31 | 6.35 | 8.38 | 17.48 |

| 14 | 350NB | 355.60 | 3.96 | 6.35 | 11.13 | 7.92 | 9.53 | 19.05 |

| 16 | 400NB | 406.40 | 4.19 | 6.35 | 12.7 | 7.92 | 9.53 | 21.44 |

| 18 | 450NB | 457.00 | 4.19 | 6.35 | 14.27 | 7.92 | 11.13 | 23.83 |

| 20 | 500NB | 508.00 | 4.78 | 6.35 | 15.09 | 9.53 | 12.70 | 26.19 |

| 22 | 550NB | 559.00 | 4.78 | 6.35 | __ | 9.53 | 12.70 | 28.58 |

| 24 | 600NB | 610.00 | 5.54 | 6.35 | 17.48 | 9.53 | 14.27 | 30.96 |

Dimensional Tolerance of Stub End MSS SP-43

| Nominal Pipe Size | 1/2 up to 2½ | 3 to 3½ | 4 | 5 to 8 | 10 to 18 | 20 to 24 |

|---|---|---|---|---|---|---|

| Outside Diameter at Welding End (OD) | 0.8 | 0.8 | 0.8 | + 1.6 – 0.8 |

+ 2.29 – 0.76 |

+ 3.05 – 0.76 |

| Overall Length (F) | 1.6 | 1.6 | 1.6 | 1.6 | 2 | 2 |

| Outside Diameter of Lap (G) | + 0 – 0.76 |

+ 0 – 0.76 |

+ 0 – 0.76 |

+ 0 – 0.76 |

+ 0 – 1.6 |

+ 0 – 1.6 |

| Thickness of Lap (T) | + 1.52 – 0 |

+ 1.52 – 0 |

+ 1.52 – 0 |

+ 1.52 – 0 |

+ 1.52 – 0 |

+ 1.52 – 0 |

| Fillet Radius of Lap (R) | + 0 – 0.76 |

+ 0 – 0.76 |

+ 0 – 1.6 |

+ 0 – 1.6 |

+ 0 – 1.6 |

+ 0 – 1.6 |

| Wall Thickness (t) | Not less than 87.5% of Nominal Wall Thickness | |||||

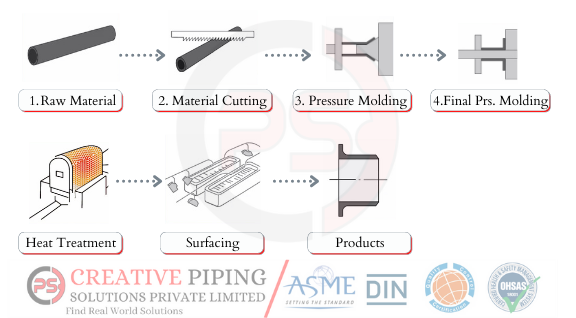

Stub End Manufacturing Proces

Stub End Application Industries

- Refineries

- Food Processing & Dairy

- Oil and Gas Industry

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Power Generation

- Specialty Chemicals

- Sea Water Equipment

- Gas Processing

- Chemical Equipment

- Heat Exchangers

- Petrochemicals

- Pharmaceuticals

- Condensers

Stub End Inspection

The Stub End Inspection checked and Tested in accordance with applicable ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. The Typical applicable codes and standards are ANSI / ASME. Our Experienced engineer team are ready to solve problem for you and take care of your industry. Our Experts Support you provide Stub End inspection controls the entire Manufacturing Process, All Stub End production progress are subject to strict in-process inspection at each stage of the Manufacturing process, from starting materials handling to finished products shipping.

Stub End Packing & Forwading

The Importance of proper packing for piping goods. it is not only protection of products or save cash but also proof of our professionalize. So for various goods, there are different protecting packing methods. For packing of Stub End with painting, We might use the bubble wrap to guard the painting. We might suggest client to use the anti-tarnish paper and bag to stop the rust. Each item is packed in poly pouches after multi stage inspections. These mini cartons are sealed and skilled Shrink Wrapping poly bag sealing machine to make sure safety from moisture. Such mini cartons are placed in bituminous hessian cloth 7 poly master carton. The contents of every master carton are shown on the carton. Each master carton is sealed with white printed heat salable strapping.

Stub End Export & Supply to below mentioned Countries

ASIA: Malaysia, India, Taiwan, Cambodia, Singapore, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Myanmar.

SOUTH AMERICA: Venezuela, Argentina, Bolivia, Colombia, Ecuador, Guyana, Paraguay, Uruguay, Brazil, Chile.

AFRICA: South Africa, Nigeria, Algeria, Angola, Libya, Egypt, Gabon, Sudan, Equatorial Guinea, The Republic Of Congo.

NORTH AMERICA: USA, Canada, Mexico, Panama, Costa Rica, Puerto Rica, Trinidad And Tobago, Jamaica, Bahamas, Denmark.

EUROPE: UK, Netherland, Russia, Norway, Germany, France, Italy, Spain, Ukraine, Belgium, Greece, Hungary, Albania, Austria, Finland, Ireland, Croatia, Slovenia, Malta, Switzerland, Slovakia, Czech Republic, Portugal.

Stub End Export & Supply to below Mentioned Cities

Mumbai, Thane, Navi Mumbai, Pune, New Delhi, Bengaluru, Chennai, Surat, New York, Caracas, Howrah, Sydney, Ahvaz, Karachi, Algiers, Pimpri-Chinchwad, Vadodara, Kolkata, Gurgaon, Ahmedabad, Chiyoda, Ankara, Ho Chi Minh City, Bhopal, Dubai, Seoul, Hyderabad, Singapore, Abu Dhabi, Tehran, Calgary, Noida, Riyadh, Vung Tau, Al Khobar, Atyrau, Lagos, Ulsan, Faridabad, Houston, Hanoi, Toronto, Hong Kong, Rajkot, Brisbane, Los Angeles, London, Muscat, Edmonton, Busan, Mexico City, Doha, Jeddah, Manama, Montreal, Thiruvananthapuram, Milan, Moscow, Dallas, Coimbatore, Jakarta, Istanbul, Bangkok, Kuwait City, Sharjah, Petaling Jaya, Ernakulam, Visakhapatnam, Ludhiana, Aberdeen, Cairo, Geoje-si, Perth, Santiago, Chandigarh, Indore, Kuala Lumpur, Rio de Janeiro, Dammam, Secunderabad, Gimhae-si, Haryana, Colombo, Lahore, Bogota, Melbourne, Madrid, La Victoria, Granada, Courbevoie, Al Jubail, Port-of-Spain.