Inconel 625 Pipe Fittings Manufacturer, ASTM B366 Inconel Alloy 625 Buttweld Fittings

ISO Certified Suppliers and Exporters of ASTM B366 Inconel 625 Buttweld Fittings, UNS N06625 Butt weld Pipe Fittings, WNR 2.4856 Seamless Pipe Fittings, ASME SB366 Inconel 625 Welded Butt weld Fittings, Werkstoff no 2.4856 Pipe Fittings, ANSI B16.9 Inconel 625 SR Elbow, Nickel Alloy 625 Pipe Fittings, UNS N06625 Pipe Elbow in India.

- Inconel 625 Pipe Fittings Specifications

- ASTM B366 Inconel 625 Buttweld Fittings Dimensions

- Inconel 625 Buttweld Pipe Fittings Types

- ANSI B16.9 Inconel 625 Pipe Fittings Forms & Availability

- ASTM B366 Inconel 625 Buttweld Fittings Standard

- Manufacturing Standards of Inconel 625 Fittings

- Equivalent Grades of ASTM B366 Inconel 625 Pipe Fittings

- Chemical Composition of Alloy 625 Buttweld Fittings

- Mechanical Properties of Inconel 625 Pipe Fittings

- Manufacturing Process of Inconel 625 Pipe Fittings

- Ready Stock of Inconel 625 Butt weld Pipe Fittings

- ASTM B366 Alloy 625 Pipe Fitting Classes for Grades

- UNS N06625 Pipe Fittings Application Industries

- Inconel 625 Buttweld Fittings Inspection

- Inconel 625 Pipe Fittings Packing & Forwarding

Largest Stockists of Inconel 625 Equal Tee, Werkstoff No 2.4856 Buttweld Elbow, ASTM B366 625 Buttweld Fittings, Inconel WNR 2.4856 Buttweld Cross, ANSI B16.9 Inconel Alloy 625 Buttweld Pipe Bend, JIS NCF 625 Dish Cap, DIN 2.4856 Butt weld Reducer, GOST ХН75МБТЮ Two Joint Pipe Fittings, AFNOR NC22DNB4M Collar Pipe Fittings, EN NiCr22Mo9Nb Buttweld Pipe Cap, BS NA 21 Long Stub End, ASME SB366 Inconel Alloy 625 Fittings.

We are Manufacturer, Supplier, and Exporter of Inconel 625 Pipe Fittings, which are being classified as difficult to moderate when machining. Inconel 625 Butt Weld Pipe Fittings must be highlighted that these alloys are often machined by using the standard production processes at suitable rates. We manufacture a good range of Alloy 625 fittings like Inconel 625 Elbow, Inconel 625 Tee, ASTM B366 Inconel 625 Reducer, Inconel 625 pipe end Cap as per International standard like ASME/ASTM/API.

Inconel 625 Reducer possesses a high degree of formability and shows better weldability than many other highly alloyed nickel-based materials. After the hydride treatment, ASTM B366 Inconel 625 Butt Weld Pipe Fittings should be immersed during an acid bath 165D Degree F (74 Degree C). Due to its good ductility, Alloy 625 Pipe Fittings also are readily formed by cold working.

Inconel 625 Cross is usually utilized in evaporators for wet-process phosphoric acid-containing H2SO4, HF, and ferric salts. Alloy 625 Pipe Fittings work as toughen with rapidly so transitional annealing conducts could be required for complex part forming actions. Alloy 625 Pipe Fittings has good impacted strength at temperature and retains virtually all of that strength at low temperatures, there’s no tough – to – brittle transition with decreasing temperature.

Inconel 625 Pipe Fittings Specifications

- Buttweld Specifications ASTM B366 / ASME SB366

- Buttweld Size Seamless Butt Weld Fittings: 1/2″ – 10″, Welded Butt Weld Fittings: 1/2″ – 48″

- Buttweld Standards/Dimensions ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

- Buttweld Type Seamless / Welded / Fabricated

- Buttweld Thickness 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS available with NACE MR 01-75

ASTM B366 Inconel 625 Buttweld Fittings Dimensions

Inconel 625 Buttweld Pipe Fittings Types

ANSI B16.9 Inconel 625 Pipe Fittings Forms & Availability

| Size | Products | |

|---|---|---|

| Sizes 1/2″ – 48″ | ASTM B366 625 Inconel Alloy Elbow – Long Radius | ASTM B366 625 Inconel Alloy Stub Ends |

| ASTM B366 625 Inconel Alloy Elbow – Short Radius | ASTM B366 625 Inconel Cross | |

| ASTM B366 625 Alloy 3D Elbow | ASTM B366 625 Inconel Alloy 5D Elbow | |

| ASTM B366 625 Inconel Alloy Reducing Elbow | ASTM B366 625 Inconel Alloy Reducing Cross | |

| ASTM B366 625 Alloy 45° Elbow | ASTM B366 625 Alloy Tees | |

| ASTM B366 625 Inconel Alloy Fabricated Tee | ASTM B366 625 Alloy End Cap | |

| ASTM B366 625 Alloy Reducer | ASTM B366 625 Alloy Coupling | |

| ASTM B366 625 Inconel Alloy Concentric Reducer | ASTM B366 625 Inconel Alloy Eccentric Reducer | |

| ASTM B366 625 Inconel Alloy Pipe Nipple | ASTM B366 625 Inconel Alloy Welded Pipe Fittings | |

ASTM B366 Inconel 625 Buttweld Fittings Standard

| American Steel Pipe Fittings Standard | |

|---|---|

| Standard Code | Standard Name |

| ANSI ASME SA-366 | Forged Durimet pipe fittings |

| ANSI ASME B16.9 | Factory-Made wrought steel pipe fittings |

| ANSI ASME B16.28 | Wrought steel butt-welding short radius elbows and returns |

| ISO 5251 | Inconel butt-welding fittings |

| MSS SP-43 | Wrought Inconel butt-welding fittings |

| MSS SP-75 | Forging butt-welding fittings |

| Japanese Steel Pipe Fittings Standard | |

| JIS B2311 | Universal steel butt-welding pipe fittings |

| JIS B2312 | Steel butt-welding pipe fittings |

| JIS B2313 | Steel plate butt-welding pipe fittings |

| German Steel Pipe Fittings Standard | |

| DIN 2605 | Steel butt-welding pipe fittings.elbows and bends |

| DIN 2615 | Steel butt-welding pipe fittings.tees |

| DIN 2616 | Steel butt-welding pipe fittings.reducers |

| DIN 2617 | Steel butt-welding pipe fittings.caps |

| Other Steel Pipe Fittings Standard | |

| EN 1025 | 3 Butt-welding pipe fittings |

Manufacturing Standards of Inconel 625 Fittings

| ASME B16.9 ASTM B366 625 Pipe Fittings | Factory-Made Wrought Buttwelding Fittings | Long Radius Elbows, Long Radius Reducing Elbows, Long Radius Returns, Short Radius Elbows, Short Radius 180-deg Rerurns, 3D elbows, Straight Tees, Straight Crosses, Reducing Outlet Tees, Reducing Outlet Crosses, Lap Joint Stub Ends, Caps, Reducers |

|---|---|---|

| ASME B16.28 | Short Radius Elbows, Short Radius 180-deg Returns | |

| Mss SP75 | Long Radius Elbows, 3R elbows, straight tees, reducing outlet tees, caps, reducers | |

| MSS SP43 | Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications | Long Radius Elbows, Straight and Reducing-on-the-Outlet Tees, Lap Joint Stub ends, caps, long radius 180 Degree returns, concentric reducers, eccentric reducers |

Equivalent Grades of ASTM B366 Inconel 625 Pipe Fittings

| STANDARD | UNS | WERKSTOFF NR. | JIS | BS | AFNOR | EN | GOST | OR |

|---|---|---|---|---|---|---|---|---|

| Inconel 625 | N06625 | 2.4856 | NCF 625 | NA 21 | NC22DNB4M | NiCr22Mo9Nb | ХН75МБТЮ | ЭИ602 |

Chemical Composition of Alloy 625 Buttweld Fittings

| Grade | C | Mn | Si | S | Al | Fe | Mo | Nb + Ta | Ti | Cr2 | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 625 | 0.10 | 0.50 | 0.50 | 0.015 | 0.40 | 5.0 | 8.0-10.0 | 3.15–4.15 | 0.40 | 20.0-23.0 | 58.0 min |

Mechanical Properties of Inconel 625 Pipe Fittings

| Grade | Density | Yield Strength (0.2%Offset) | Melting Point | Tensile Strength | Elongation |

|---|---|---|---|---|---|

| 625 | 8.4 g/cm3 | Psi – 75,000 , MPa – 517 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa -930 | 42.5 % |

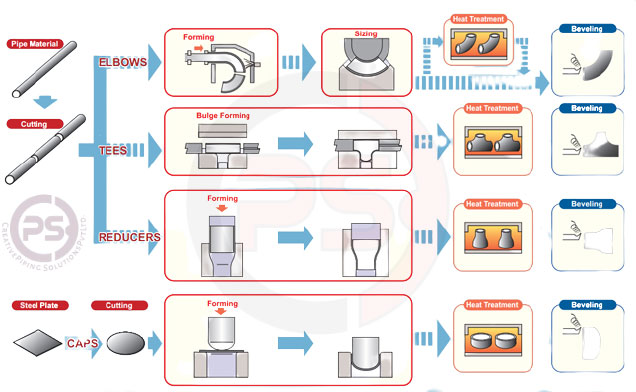

Manufacturing Process of Inconel 625 Pipe Fittings

Ready Stock of Inconel 625 Butt weld Pipe Fittings

| Inconel 625 90° LR Elbow | 625 Inconel Seamless Pipe Fittings |

| Inconel 625 90° Weldable SR Elbow | Alloy UNS N06625 Pipe Reducers |

| ASME B16.9 Inconel 625 90° Reducing Elbow | 625 Nickel Alloy Welded Pipe Fittings |

| MSS SP-43 Inconel 625 Stub End | ASTM B366 625 Inconel Caps |

| Inconel NA 21 Pipe Fittings Supplier | B366 625 Two Joint Pipe Fittings |

| ASTM B366 Inconel 625 Reducing Tee | ASTM B366 625 Lateral Tee |

| Sch 10 Inconel 625 Concentric Reducer | Inconel® Alloy 625 Welded Pipe Fittings |

| Sch 80 Nickel Alloy 625 Eccentric Reducer | B366 Grade 625 Industrial Buttweld Pipe Fittings |

| 6 Inch Inconel Alloy 625 Buttweld Pipe Fittings | 625 Inconel Buttweld Reducing Nipple |

| Inconel Alloy 625 Seamless Buttweld Fittings | Sch 80 Inconel 625 Pipe Fittings |

| ASTM B366 Inconel 625 Eccentric Reducer | ASME B16.9 Inconel NiCr22Mo9Nb 10D Elbow |

| NiCr22Mo9Nb Inconel® Alloy Two Joint Pipe Fittings | 625 Inconel LR Elbow |

| Alloy 625 Wrought Austenitic 45 Degree Elbow | ASTM B366 625 Welded Pipe Fittings |

| Inconel 2.4856 Pipe Fittings Dimensions | Inconel NA 21 Buttweld Reducing Nipple |

| Wrought Austenitic Inconel 625 Pipe Fittings | ASTM B366 625 Eccentric Reducer |

| Alloy NiCr22Mo9Nb Equal Cross | Suppliers of 625 Nickel Alloy End Pipe Cap |

ASTM B366 Alloy 625 Pipe Fitting Classes for Grades

CR : Corrosion resistant grade. S through WU Classes do not apply.

625-S : Seamless

625-W : Welded, Weldable, RT or UT all pipe starting material welds made with filler metal. All fitting manufacturer welds except as excluded in A/SB366

If UT is substituted for RT, all welds must be examined 100% for their length as required by A/SB366

625-WX : RT all welds with or without filler metal.

625-WU : UT all welds with or without filler metal.

grade-grade-class : Insert grades (625) and class (S,W,WX, or WU). Applies to fittings meeting all chemical and physical requirements of both grades.

UNS N06625 Pipe Fittings Application Industries

We Produce full range of Inconel Alloy 625 Fittings in every sizes, pressure / classes, dimensions to meet needs of customers. Our Inconel 625 Pipe Fittings are well accepted by the majority of customers. it’s widely used in aerospace, shipbuilding, metallurgy, automotive instrumentation, petrochemical, food machinery, biological engineering In the field of environmental protection.

- Refineries

- Food Processing & Dairy

- Oil and Gas Industry

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Power Generation

- Specialty Chemicals

- Sea Water Equipment

- Gas Processing

- Chemical Equipment

- Heat Exchangers

- Petrochemicals

- Pharmaceuticals

- Condensers

Inconel 625 Buttweld Fittings Inspection

We at Creative Piping Solutions ensures that all our material go through strict quality test before dispatching them to our clients. We conduct all necessary test of Inconel Alloy 625 Buttweld Pipe Fittings to assure the quality of deliver products to fit clients projects and needs. NDT test used for Inconel 625 Buttweld Fittings are Positive material identification (PMI), Penetrating liquids, Ferrite content, Hydrostatic test / hydro testing (pressure testing), Magnetic particles, Macrography, Micrography, Pneumatic pressure, Radiography. All of the listed test, the pressure testing is one of the most commonly specified, especially for mission critical Pipe Fittings in the pipeline.

Inconel 625 Pipe Fittings Packing & Forwarding

There are different ways of packing a Inconel 625 Fittings, but two principles that are vital for any method to work prevent rusting and Sea transportation security. Our all Inconel Alloy 625 Pipe Fittings packed with seaworthy packing method then delivery to customers, usually the packing way include wooden box, wooden pallet. We make sure that it is seaworthy, strong, waterproof and easy for loading and unloading. All shipping and product details also stick to outside of package. Alloy 625 Pipe Fittings pack with environmental poly bags, and then in free fumigation wooden cases or plate. Alloy 625 Buttweld Pipe Fittings are packed in wooden corrugated boxes foiled in bubble wraps and plastic wraps.

ASTM B366 Inconel 625 Pipe Fittings Export & Supply to below mentioned Countries

ASIA: Malaysia, India, Taiwan, Cambodia, Singapore, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Myanmar.

SOUTH AMERICA: Venezuela, Argentina, Bolivia, Colombia, Ecuador, Guyana, Paraguay, Uruguay, Brazil, Chile.

AFRICA: South Africa, Nigeria, Algeria, Angola, Libya, Egypt, Gabon, Sudan, Equatorial Guinea, The Republic Of Congo.

NORTH AMERICA: USA, Canada, Mexico, Panama, Costa Rica, Puerto Rico, Trinidad, And Tobago, Jamaica, Bahamas, Denmark.

EUROPE: UK, Netherlands, Russia, Norway, Germany, France, Italy, Spain, Ukraine, Belgium, Greece, Hungary, Albania, Austria, Finland, Ireland, Croatia, Slovenia, Malta, Switzerland, Slovakia, Czech Republic, Portugal.