Pipe Spool Manufacturer, Pre-Fabricated Piping Spools Suppliers

Pipe Spools Suppliers, Check Jacket Piping Spool Dimensions & Jacketed Piping Spool Price List, Jacket Piping Spool Manufacturer in India

ANSI / ASME B 36.10 & B 36.19 Industrial Piping Spool Exporters in India, Fabricated Pipe Spools Suppliers in South Africa, Malaysia, Singapore, UK, Philippines, Australia and UAE.

Creative Piping Solutions is a Manufacturing and Supplying a good range of optimum quality Piping Spools. The said product is a kind of a bunch of pipes that are used for conveying liquids like water, oil. and gases from one end to a different one. It’s fabricated using high-grade materials. to form it sturdy in construction, rust-free, high strength enduring then on. Piping Spool provides high-performance efficiency, abrasion resistance, optimum service, smooth functioning, longer service life, seamless finishing, and lots of other properties.

We are the leading Manufacturer of Piping Spool Jacket Piping Spools which are utilized in Power plants, Refineries, Pharmaceutical Plants, Chemical Plants, and other Process Plant. All Pipe Spools start with a singular serial number. This ensures that each drawing, material, man-hours, and processes are tracked and maintained for the customer. Our given range is formed using the highest quality raw materials and modern technology. These are often availed from us at an affordable price.

Pipe spools are the rebuild parts of a piping system. Pipes, flanges, and fittings are called pipe spools, and that they are produced before they’re utilized in the piping system. Pipe spools are reshaped to form easier assemble using hoists, gauges, and other tools for joining the parts. Pipe spools unite long pipes with flanges from the top of the long pipes in order that they are often bolted with one another with matching flanges. These connections are embedded inside concrete walls before the pouring of concrete. this technique must be aligned properly before concrete pouring because it must withstand the load and force of the structure.

Creative Piping Solutions is a trusted manufacturers of Rubber Lined Pipe Spool, FBE Coating Pipe Spool, Flanged Pipe Spool, Stainless Steel Pipe Spool, Carbon & Alloy Steel Pipe Spool, Duplex & Super Duplex Pipe Spool, High Nickel Alloys Pipe Spool.

Steel Pipe Spools Specifications

- Type Steel Pipe Spool

- Size 114mm to 2500mm diameter (Seamless & Welded, Fabricated)

- Operating Pressures Maximum 3500kPa

- Maximum Velocities 6m/s for cement mortar lined fittings

- Operating Temperatures -40˚C to 70˚C

- In Form spool

- Standard ANSI / ASME B 36.10 & B 36.19

- Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40

- Thickness 10s/3 mm to XXS/70 mm

- Specialize As per drawing

- Dimensions ANSI / ASME B 36.10 & B 36.19

- Usage/Applications Oil Field, Offshore, Water System, Shipbuilding, Natural Gas, Electric Power, Pipe Projects.

Similar Products: Forged Fittings | Flanges | Buttweld Fittings | Materials

Pipe Spools Range

| Consturction | Size Range | Schedule / Thickness | |

|---|---|---|---|

| Min Thk (mm) | Max Thk (mm) | ||

| Seamless Fabricated | 0.5″ to 30″ | 10s/3 mm | XXS/85 mm |

| Seamless Fabricated | 0.5″ to 30″ | 10s/3 mm | XXS/85 mm |

| Welded Fabricated | 0.5″ to 48″ | 10s/8 mm | XXS/85 mm |

| Seamless Fabricated | 0.5″ to 24″ | 10s/3 mm | XXS/70 mm |

| Welded Fabricated | 0.5″ to 96″ | 10s/8 mm | XXS/85 mm |

| Welded Fabricated | 0.5″ to 74″ | 10s/6 mm | XXS/70 mm |

Pre-Fabrication of Pipe Spools

Roll correction and welding process are fitting of the main pipe by rolling machine and therefore, and also the position of fitting and welding occur when over one branch of the long pipe overcome the clearance limit. To make a more efficient piping system, and save time, pipe spool prefabrication is used. Because the system did, ‘t produce preliminary, the welding of the system will take far more time, and therefore, the welder has got to give way the most pipe to accomplish fitting or welding.

Why pipe spools are Pre-fabricated?

Pipe Spools are prefabricated to reduce field installation costs and supply higher quality products. They’re generally flanged to get the connection to other spools. The spool fabrication is generally performed by special companies having the specified infrastructure. These specialist fabricators produce the system under the required set of quality and accuracy to get a proper fit at the positioning and to maintain the required technical properties defined by the client.

ANSI / ASME B 36.10 & B 36.19 Pipe Spool Dimensions, Size and Schedule

| DN/NPS (Inch) | OD (mm) | 5S | 10S | 10 | 20 | 30 | STD | 40S | 40 | 60 | XS | 80S | 80 | 100 | 120 | 140 | 160 | XXS |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/8 | 10.3 | – | 1.42 | – | – | – | 1.73 | 1.73 | 1.73 | – | 2.41 | 2.41 | 2.41 | – | – | – | – | – |

| 1/4 | 13.7 | – | 1.65 | – | – | – | 2.24 | 2.24 | 2.24 | – | 3.02 | 3.02 | 3.02 | – | – | – | – | – |

| 1 | 33.4 | 1.65 | 2.77 | – | – | – | 3.38 | 3.38 | 3.38 | – | 4.55 | 4.55 | 4.55 | – | – | – | 6.35 | 9.09 |

| 1 1/4 | 42.2 | 1.65 | 2.77 | – | – | – | 3.56 | 3.56 | 3.56 | – | 4.85 | 4.85 | 4.85 | – | – | – | 6.35 | 9.7 |

| 1 1/2 | 48.3 | 1.65 | 2.77 | – | – | – | 3.68 | 3.68 | 3.66 | – | 5.08 | 5.08 | 5.08 | – | – | – | 7.14 | 10.15 |

| 3/8 | 17.1 | – | 1.65 | – | – | – | 2.31 | 2.31 | 2.31 | – | 3.2 | 3.2 | 3.2 | – | – | – | – | – |

| 1/2 | 21.3 | 1.65 | 2.11 | – | – | – | 2.77 | 2.77 | 2.77 | – | 3.73 | 3.73 | 3.73 | – | – | – | 4.78 | 7.47 |

| 3/4 | 26.7 | 1.65 | 2.11 | – | – | – | 2.87 | 2.87 | 2.87 | – | 3.91 | 3.91 | 3.91 | – | – | – | 5.56 | 7.82 |

| 2 | 60.3 | 1.65 | 2.77 | – | – | – | 3.91 | 3.91 | 3.91 | – | 5.54 | 5.54 | 5.54 | – | – | – | 8.74 | 11.07 |

| 2 1/2 | 73 | 2.11 | 3.05 | – | – | – | 5.16 | 5.16 | 5.16 | – | 7.01 | 7.01 | 7.01 | – | – | – | 9.53 | 14.02 |

| 3 | 88.9 | 2.11 | 3.05 | – | – | – | 5.49 | 5.49 | 5.49 | – | 7.62 | 7.62 | 7.62 | – | – | – | 11.13 | 15.24 |

| 3 1/2 | 101.6 | 2.11 | 3.05 | – | – | – | 5.74 | 5.74 | 5.74 | – | 8.08 | 8.08 | 8.08 | – | – | – | – | – |

| 12 | 323.9 | 3.96 | 4.57 | – | 6.35 | 8.38 | 9.53 | 9.52 | 10.31 | 14.27 | 12.7 | 12.7 | 17.48 | 21.44 | 25.4 | 28.58 | 33.32 | 25.4 |

| 14 | 355.6 | 3.96 | 4.78 | 6.35 | 7.92 | 9.53 | 9.53 | – | 11.13 | 15.09 | 12.7 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | – | |

| 16 | 406.4 | 4.19 | 4.78 | 6.35 | 7.92 | 9.53 | 9.53 | – | 12.7 | 16.66 | 12.7 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | – | |

| 18 | 457 | 4.19 | 4.78 | 6.35 | 7.92 | 11.13 | 9.53 | – | 14.27 | 19.05 | 12.7 | 23.88 | 29.36 | 34.93 | 39.67 | 45.24 | – | |

| 20 | 508 | 4.78 | 5.51 | 6.35 | 9.53 | 12.7 | 9.53 | – | 15.09 | 20.62 | 12.7 | 26.19 | 32.54 | 38.1 | 44.45 | 50.01 | – | |

| 22 | 559 | 4.78 | 5.54 | 6.35 | 9.53 | 12.7 | 9.53 | – | – | 22.23 | 12.7 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | – | |

| 24 | 610 | 5.54 | 6.35 | 6.35 | 9.53 | 14.27 | 9.53 | – | 17.48 | 24.61 | 12.7 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | – | |

| 4 | 114.3 | 2.11 | 3.05 | – | – | – | 6.02 | 6.02 | 6.02 | – | 8.56 | 8.56 | 8.56 | – | 11.13 | – | 13.49 | 17.12 |

| 5 | 141.3 | 2.77 | 3.4 | – | – | – | 6.55 | 6.55 | 6.55 | – | 9.53 | 9.53 | 9.53 | – | 12.7 | – | 15.88 | 19.05 |

| 6 | 168.3 | 2.77 | 3.4 | – | – | – | 7.11 | 7.11 | 7.11 | – | 10.97 | 10.97 | 10.97 | – | 14.27 | – | 18.2 | 21.95 |

| 8 | 219.1 | 2.77 | 3.76 | – | 6.35 | 7.04 | 8.18 | 8.18 | 8.18 | 10.31 | 12.7 | 12.7 | 12.7 | 15.09 | 18.26 | 20.62 | 23.01 | 22.23 |

| 10 | 273.1 | 3.4 | 4.19 | – | 6.35 | 7.8 | 9.27 | 9.27 | 9.27 | 12.7 | 12.7 | 12.7 | 15.09 | 18.26 | 21.44 | 25.4 | 28.58 | 25.4 |

| 26 | 660 | – | – | 7.92 | 12.7 | – | 9.53 | – | – | – | 12.7 | – | – | – | – | – | – | |

| 28 | 711 | – | – | 7.92 | 12.7 | 15.88 | 9.53 | – | – | – | 12.7 | – | – | – | – | – | – | – |

| 30 | 762 | 6.35 | 7.92 | 7.92 | 12.7 | 15.88 | 9.53 | – | – | – | 12.7 | – | – | – | – | – | – | – |

| 32 | 813 | – | – | 7.92 | 12.7 | 15.88 | 9.53 | – | 17.48 | – | 12.7 | – | – | – | – | – | – | – |

| 42 | 1067 | – | – | – | – | – | 9.53 | – | – | – | 12.7 | – | – | – | – | – | – | – |

| 44 | 1118 | – | – | – | – | – | 9.53 | – | – | – | 12.7 | – | – | – | – | – | – | – |

| 46 | 1168 | – | – | – | – | – | 9.53 | – | – | – | 12.7 | – | – | – | – | – | – | – |

| 34 | 864 | – | – | 7.92 | 12.7 | 15.88 | 9.53 | – | 17.48 | – | 12.7 | – | – | – | – | – | – | – |

| 36 | 914 | – | – | 7.92 | 12.7 | 15.88 | 9.53 | – | 19.05 | – | 12.7 | – | – | – | – | – | – | – |

| 38 | 965 | – | – | – | – | – | 9.53 | – | – | – | 12.7 | – | – | – | – | – | – | – |

| 40 | 1016 | – | – | – | – | – | 9.53 | – | – | – | 12.7 | – | – | – | – | – | – | – |

| 48 | 1219 | – | – | – | – | – | 9.53 | – | – | – | 12.7 | – | – | – | – | – | – | – |

Piping Spools Materials

Stainless Steel Pipe Spool :

- ASTM / ASME A/SA 182: F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L.

Duplex & Super Duplex Steel Pipe Spool :

- ASTM / ASME A/SA 182: F44, F45, F51, F53, F55, F60, F61.

Nickel Alloy Pipe Spool :

- ASTM / ASME SB 564 / 160 / 472: UNS 2200 (NICKEL 200), UNS 4400 (MONEL 400), UNS 8825 INCONEL (825), UNS 6600(INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276), UNS 2201 (NICKEL 201), (ALLOY 20 / 20 CB 3)

Copper Alloy Pipe Spool :

- ASTM / ASME SB 61 / 62 / 151 / 152: UNS NO. C 92200, UNS NO. C 83600, UNS NO. 70600, 71500, C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30), UNS NO C 10100, C 10200, C 10300, C 10800, C 12000, C 12200

Carbon Steel Pipe Spool :

- ASTMA 105/A694/ A350 LF3/A350 LF2: F42, F46, F52, F56, F60, F65, F70

Alloy Steel Pipe Spool :

- ASTM A182: F1, F5, F9, F11, F22, F91

Brass Forged Steel Pipe Spool :

- Brass CA 360, CA 345 and CA 377 / SAE J530, SAE J531 and ASA

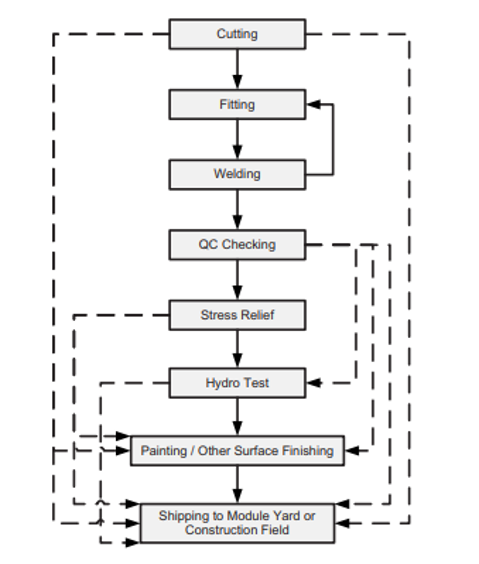

ANSI / ASME B 36.10 & B 36.19 Pipe Spool Manufacturing Process

Piping Spools are produced by the usage of Raw Pipe and Fittings. The cutting process of the Raw Pipes is finished with a specified size that is suitable for the pipe fitting and other components. Pipe Spools are fabricated using various sorts of raw pipes and pipe fittings, and they include flanges, elbows, tees, and a lot more. They’re usually fabricated offsite. The raw pipes are present in specific sizes and along with pipe fittings and other components. They’re temporarily fitted together. This partially finished sub-assembly is then welded with another spool component.

There are two main parts of the Pipe Spooling Process:

- Roll Correction and welding

- Durable position Fitting and Welding

In Pipe Spool Roll Fitting and Welding, the main pipe is often turned using a rolling machine, and therefore, the fitter does not get to alter his position to perform the task. In spool position fitting and welding, some or portions of most pipe go beyond the clearance limit forcing the fitter to maneuver around the main pipe to finish the fitting and weld process. That’s why spool position fitting and welding is usually an extended process compared to spool roll fitting and welding. Reducing the amount of spool position fitting and welding is one of the objectives of pipe spool fabrication sequencing.

Pre-Fabrication Pipe Spool Advantages

- The quality of the work is simpler to manage and maintain.

- Specified tolerances avoid rework at the positioning due to high accuracy.

- Fabrication is weather independent, so, it minimizes the assembly delays.

- The prefabrication process is the best advantage because it provides less workforce for the fabrication of spools on site.

- Mass production manufacturing leads to lower manufacturing costs as compared with site fabrication.

- Lesser fabrication and assembly time needed for prefabricated spools, with this manner, additional time, and price wastage is avoided.

- Prefabricated spools want little investments in production, and testing equipment by the users. For better and efficient performances, Radiography, PMI, MPI, Ultrasonic tests, Hydro tests, etc. will be used.

- To obtain a lesser probability of rework at the positioning, better control of welding parameters must be wiped out the controlled environments.

- Power availability isn’t necessary.

- Unnecessary time delays are avoided.

Disadvantages of Pipe Spool

The main disadvantage is the not fitting on site. This problem causes terrible results. One small mistake within the reproduction of pipe spools causes a non-fitting system within the working environment and creates an oversized problem. When this problem occur, pressure test and x-ray of the weld must be checked again and re-welding should be needed.

Pipe Spooling Application Industries

- Refineries

- Food Processing & Dairy

- Oil and Gas Industry

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Power Generation

- Specialty Chemicals

- Sea Water Equipment

- Gas Processing

- Chemical Equipment

- Heat Exchangers

- Petrochemicals

- Pharmaceuticals

- Condensers

Pipe Spool Inspection

The Piping Spool Inspection checked and tested in accordance with applicable ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. The typical applicable codes and standards are ANSI / ASME B 36.10 & B 36.19. our experienced engineer team are ready to solve problem for you and take care of your industry. Our experts support you provide Steel Pipe Spool inspection controls the entire manufacturing process, All Pipe Spooling production progress are subject to strict in-process inspection at each stage of the Manufacturing process, from starting materials handling to finished products shipping.

Pipe Spool Packing & Forwading

The importance of proper packing for piping goods. it is not only protection of products or saves cash but also proof of our professionalism. So for various goods, there are different protective packing methods. For packing Pipe Spools with painting, we might use bubble wrap to guard the painting. we might suggest client to use the anti-tarnish paper and bag to stop the rust. Each item is packed in poly pouches after multi-stage inspections. These mini cartons are sealed and skilled Shrink Wrapping poly bag sealing machine to make sure safety from moisture. Such mini cartons are placed in bituminous hessian cloth 7 poly master cartons. The contents of every master carton are shown on the carton. Each master carton is sealed with white printed heat salable strapping.

Steel Pipe Spool Export & Supply to below mentioned Countries

ASIA: Malaysia, India, Taiwan, Cambodia, Singapore, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Myanmar.

SOUTH AMERICA: Venezuela, Argentina, Bolivia, Colombia, Ecuador, Guyana, Paraguay, Uruguay, Brazil, Chile.

AFRICA: South Africa, Nigeria, Algeria, Angola, Libya, Egypt, Gabon, Sudan, Equatorial Guinea, The Republic Of Congo.

NORTH AMERICA: USA, Canada, Mexico, Panama, Costa Rica, Puerto Rica, Trinidad And Tobago, Jamaica, Bahamas, Denmark.

EUROPE: UK, Netherland, Russia, Norway, Germany, France, Italy, Spain, Ukraine, Belgium, Greece, Hungary, Albania, Austria, Finland, Ireland, Croatia, Slovenia, Malta, Switzerland, Slovakia, Czech Republic, Portugal.

Pipe Spool Export & Supply to below Mentioned Cities

Mumbai, Thane, Navi Mumbai, Pune, New Delhi, Bengaluru, Chennai, Surat, New York, Caracas, Howrah, Sydney, Ahvaz, Karachi, Algiers, Pimpri-Chinchwad, Vadodara, Kolkata, Gurgaon, Ahmedabad, Chiyoda, Ankara, Ho Chi Minh City, Bhopal, Dubai, Seoul, Hyderabad, Singapore, Abu Dhabi, Tehran, Calgary, Noida, Riyadh, Vung Tau, Al Khobar, Atyrau, Lagos, Ulsan, Faridabad, Houston, Hanoi, Toronto, Hong Kong, Rajkot, Brisbane, Los Angeles, London, Muscat, Edmonton, Busan, Mexico City, Doha, Jeddah, Manama, Montreal, Thiruvananthapuram, Milan, Moscow, Dallas, Coimbatore, Jakarta, Istanbul, Bangkok, Kuwait City, Sharjah, Petaling Jaya, Ernakulam, Visakhapatnam, Ludhiana, Aberdeen, Cairo, Geoje-si, Perth, Santiago, Chandigarh, Indore, Kuala Lumpur, Rio de Janeiro, Dammam, Secunderabad, Gimhae-si, Haryana, Colombo, Lahore, Bogota, Melbourne, Madrid, La Victoria, Granada, Courbevoie, Al Jubail, Port-of-Spain.