Alloy Steel F9 Flanges Manufacturer, Alloy Steel ASTM A182 F9 Flange

ISO Certified Suppliers and Exporters of ASTM A182 Alloy Steel F9 Flanges, F9 Chrome Moly Flanges, ASME SA182 Alloy Steel F9 Flanges, ANSI B16.5 Alloy Steel A182 F9 Weld Neck Flanges, WNR 1.7386 Slip-on Flanges, UNS K90941 Blind Flanges, Alloy Steel A182 F9 Industrial Flanges in India.

- Alloy Steel F9 Flanges Specifications

- ASTM A182 Alloy Steel F9 Flanges Dimensions

- ASTM A182 Alloy Steel F9 Flanges Types

- ANSI B16.5 Alloy Steel F9 Flange Forms & Availability

- Alloy Steel F9 Flanges Standard

- Equivalent Grades of Alloy Steel F9 Flanges

- Chemical Composition of Alloy Steel F9 Plate Flanges

- Mechanical Properties of Alloy Steel A182 F9 Forged Flanges

- Schedule / Class of Alloy Steel A182 F9 Flanges

- Ready Stock of Alloy Steel F9 Flanges

- Manufacturing Standards of Alloy Steel F9 Plate Flange

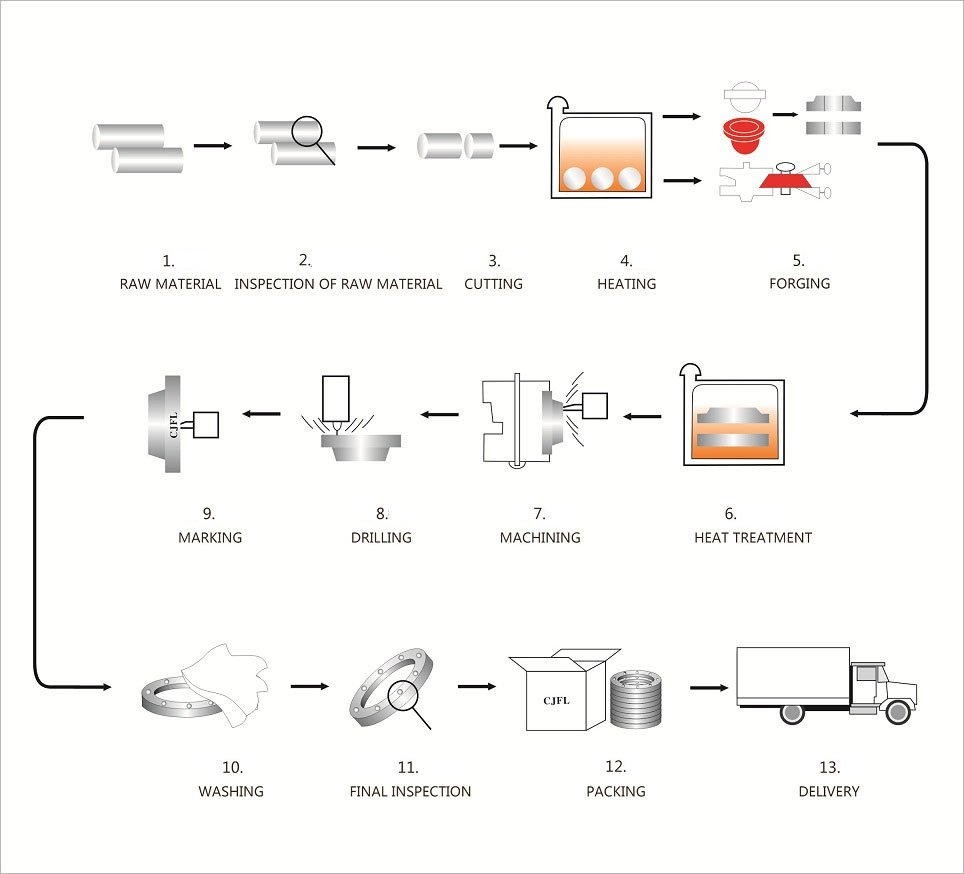

- Manufacturing Process of Alloy Steel ASTM A182 F9 Flanges

- Alloy Steel ASTM A182 F9 Flanges Application Industries

- ASTM A182 Alloy Steel F9 Flanges Inspection

- ASTM A182 Alloy Steel F9 Flanges Inspection

Largest stockists of Alloy Steel F9 Forged Flanges, Werkstoff No 1.7386 SWRF Flanges, Alloy Steel F9 Slip on Flange, WNR 1.7386 Reducing Flanges, UNS K90941 Weld Neck Flanges, DIN 1.7386 Socket weld Flange, UNS K90941 Threaded Flanges, Alloy Steel F9 SORF Flanges, ASTM A182 F9 Long Weld Neck Flanges, ASTM A182 Alloy Steel F9 Lap Joint Flanges, ASME SA182 F9 RTJ Flanges.

Creative Piping Solutions are an approved Manufacturer, Supplier, and Exporter of alloy steel F9 Flanges. We Manufacture A182 F9 Flanges in various shapes, sizes, grades & specifications consistent with international standards. We’ve marked our place in national also as global markets due to the standard of our product. We focus our attitude towards the satisfaction of consumers and expertise in our work.

The AS F9 Flanges are thinner as compared to other flanges. Therefore, the ASTM A182 F9 Blind Flange tends to suit well in compact workspaces. The A182 F9 material contains some amount of chromium and molybdenum, both of which help in maintaining longevity thereby having an extended service life. Further, the addition of both chromium and molybdenum, within the A182 grade F9 Flanges enhances the corrosion resistance of the flanges. The A182 F9 Flanges are considered a cost-saving option. Besides these properties, The ASTM A182 F9 Flanges are reusable also as corrosion-free.

We Stock differing types of ASTM A182 F9 Flanges are available within the following pressure classes – 300lb, 400lb, 600lb, 150lb, 900lb, 1500lb and 2500lb. There are several forms and kinds available like slip-on, blind, Orifice Flanges, Threaded Flanges, and Forged Flanges. ASME SA234 F9 Pipe Flanges is a nickel, iron, chromium austenitic alloy that was created for max resistance to acid attack, specifically vitriol.

Alloy Steel F9 Flanges Specifications

- Specifications ASTM A182 / ASME SA182

- Size 1/2″ (15 NB) to 48″ (1200NB)

- Standards/Dimensions ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

- Class / Pressure 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

- Face Type Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

- Flange Form SORF, WNRF, BLRF, SWRF, LAP Joint, Threaded, Reducing, Spectacle, etc

- Flange Connection Type Ring Type Joint, Lap-Joint Face, Raised Face, Flat Face, Large Male-Female, Small Male-Female, Large, Tongue & Groove, Small Tongue & Groove

- Flange Coating Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized

- Flange Test Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector

- Flange Origin Indian / West Europe / Japan / USA / Korean

ASTM A182 Alloy Steel F9 Flanges Dimensions

ASTM A182 Alloy Steel F9 Flanges Types

ANSI B16.5 Alloy Steel F9 Flange Forms & Availability

| Size | Products | |

|---|---|---|

| Sizes 1/8″ – 36″ Raised Face or Flat Face |

ASTM A182 Alloy Steel F9 Slip-On Flanges | ASTM A182 Alloy Steel F9 Threaded Flanges |

| ASTM A182 Alloy Steel F9 Weld Neck Flanges | ASTM A182 Alloy Steel F9 Socket Weld Flanges | |

| ASTM A182 Alloy Steel F9 Blind Flanges | ASTM A182 Alloy Steel F9 Reducing Flanges | |

| ASTM A182 Alloy Steel F9 Lap Joint Flanges | ASTM A182 Alloy Steel F9 Plate Flanges | |

| ASTM A182 Alloy Steel F9 Orifice Flanges | ASTM A182 Alloy Steel F9 Forged Flanges | |

| ASTM A182 Alloy Steel F9 Ring Type Joint Flanges | ASTM A182 Alloy Steel F9 Square Flanges | |

Alloy Steel F9 Flanges Standard

| American Steel Flanges Standard | Standard Code | ANSI ASME B16.5 | ASME – B 16.47 | ASME – B 16.36 | |||

|---|---|---|---|---|---|---|---|

| Standard Name | Welding neck flange, Blind flange, Slip on flange, Lap joint flange, Threaded flange, RTJ flange | Blind flange, Welding neck flange | Welding neck flange, Slip on flange | ||||

| German Steel Flanges Standard | DIN 2527 | DIN 2573 / 2576 | DIN 2673 | DIN 2641 / 2642 | DIN 28115 | DIN PN10, PN16 | DIN PN20, PN25 |

| Steel Blind Flanges, BLRF | Flat Flange for Welding (Slip On) | Loose Flanges and Rings for Welding (Slip On Flanges and Plain Collars) | Lapped / Loose (Lap Joint) Flanges Plain Collars | Long Neck Welding Flanges | Alloy Steel F9 DIN PN 10 Flanges, Alloy Steel F9 PN10 Flanges, Alloy Steel F9 PN16 Flange | Alloy Steel F9 DIN PN 25 Flanges, Alloy Steel F9 PN20 Flanges | |

| Japanese Steel Flanges Standard | JIS B2220 | JIS B2291 | JIS 5K, 10K | JIS 16K, 20K | JIS 30K, 40K | ||

| Slipon plate flange (SOP), Slipon Hub (SOH), Lapjoint (LJ), Welding neck flange (WN), Socket Welding flange (SW), Threaded flange (TR)/ Itegral flange (IT) Blank flange (BL) | Slipon plate flange (SOP), Welding neck flange (WN), Lapjoint (LJ), Slipon Hub (SOH), Socket Welding flange (SW), Threaded flange (TR)/ Itegral flange (IT) Blank flange (BL) | Alloy Steel F9 5K SORF Flanges, 10K SOFF Flanges | Alloy Steel F9 16K Blind Flanges, 20K BLRF Flanges | Alloy Steel F9 30K Slip on Flanges, 40K Blind Flanges | |||

| Italian Flanges Standard | UNI FLANGES | ||||||

| Plan flanges (2276, 2277, 2278, 6083, 6084) Lapped flanges (6088, 6089, 6090, 2999, 2300) Welding neck (2280, 2281, 2282, 2283, 2284, 2285, 2286) threaded flanges (2253, 2254) Blind flanges (6091, 6092, 6093, 6094, 6095, 6096, 6097) | |||||||

| British Standard Pipe Flanges Standard | BS 10 Table D | BS 10 Table E | BS 10 Table F | BS 10 Table H | |||

| Alloy Steel F9 BS 10 Table D Flanges, Table D Pipe Flange | Alloy Steel F9 BS 10 Table E Flanges, Table E Pipe Flange | Alloy Steel F9 BS 10 Table E Flanges, Table E Flanges | Alloy Steel F9 BS 10 Table E Flanges, Table E Pipe Flanges |

Equivalent Grades of Alloy Steel F9 Flanges

| STANDARD | UNS | WERKSTOFF NR. | Trade Name |

|---|---|---|---|

| Alloy Steel F9 | K90941 | 1.7386 | 9Cr-1Mo |

Chemical Composition of Alloy Steel F9 Plate Flanges

| Grade | C | Mn | S | Cr | Si | P | Mo |

|---|---|---|---|---|---|---|---|

| Alloy Steel F9 | 0.15 max | 0.3-0.6 | 0.03 | 8 – 10 | 0.5 – 1 | 0.03 | 0.9 – 1.1 |

Mechanical Properties of Alloy Steel A182 F9 Forged Flanges

| Grade | Yield Strength 0.2% Proof (MPa) min | Tensile Strength (MPa) min | Elongation (% in 50mm) min |

|---|---|---|---|

| Alloy Steel F9 | 585 | 380 | 20 |

Schedule / Class of Alloy Steel A182 F9 Flanges

| Flange Schedule/Class | Flange Connection Type | Flange Material | Pipe Size – Pipe Flanges | Max. Pressure |

|---|---|---|---|---|

| ASME B16.5 Class 150 | FNPT | Alloy Steel F9 Flanges | 1/2″ | 150 psi |

| ASME B16.5 Class 150 | Socket Weld | Cr-Mo F9 Flanges | 1/2″ | 275 psi |

| ASME B16.5 Class 150 | Welded | Alloy Steel F9 Flanges | 1/2″ | 150 psi |

| ASME B16.5 Class 150 | FNPT | Cr-Mo A182 F9 Flanges | 3/4″ | 150 psi |

| ASME B16.5 Class 150 | Socket Weld | Alloy Steel F9 Flanges | 3/4″ | 275 psi |

| ASME B16.5 Class 150 | Socket Weld | CrMo F9 Flanges | 1-1/4″ | 275 psi |

| ASME B16.5 Class 150 | Socket Weld | Alloy Steel F9 Flanges | 1-1/2″ | 275 psi |

| ASME B16.5 Class 150 | FNPT | Cr-Mo F9 Flanges | 2″ | 150 psi |

| ASME B16.5 Class 150 | Socket Weld | Alloy Steel A182 F9 Flanges | 2″ | 275 psi |

| ASME B16.5 Class 150 | Socket Weld | Cr-Mo F9 Flanges | 2-1/2″ | 275 psi |

| ASME B16.5 Class 150 | Socket Weld | Alloy Steel F9 Flanges | 3″ | 275 psi |

| ASME B16.5 Class 150 | FNPT | Cr-Mo F9 Flanges | 4″ | 150 psi |

| ASME B16.5 Class 150 | Socket Weld | Alloy Steel F9 Flanges | 4″ | 275 psi |

| ASME B16.5 Class 300 | Slip On | Cr-Mo F9 Flanges | 1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | Alloy Steel A182 F9 Flanges | 1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | CrMo F9 Flanges | 1″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | Alloy Steel F9 Flanges | 1″ | 720 psi |

| ASME B16.5 Class 300 | FNPT | Cr-Mo F9 Flanges | 1-1/4″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | Alloy Steel F9 Flanges | 1-1/4″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | Cr-Mo F9 Flanges | 1-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | Alloy Steel F9 Flanges | 1-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | Cr-Mo F9 Flanges | 2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | Alloy Steel F9 Flanges | 2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | CrMo F9 Flanges | 2-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | Alloy Steel F9 Flanges | 2-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | Cr-Mo F9 Flanges | 3″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | Alloy Steel A182 F9 Flanges | 3″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | Cr-Mo F9 Flanges | 4″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | Alloy Steel F9 Flanges | 4″ | 720 psi |

Ready Stock of Alloy Steel F9 Flanges

| ASME SA182 Alloy Steel F9 BLRF Flange | ASTM A182 Alloy Steel F9 Raised Face Flanges |

| UNS K90941 Nipoflange | Duplex K90941 Reducing Flanges |

| ANSI B16.5 Alloy Steel F9 Pipe Flange | Alloy Steel F9 Ring Type Joint Flanges |

| UNS K90941 Orifice Flange | Alloy Steel F9 Spectacle Blind Flanges |

| Alloy Steel F9 PN 10 Flange | PN 16 Duplex K90941 Flanges |

| Alloy Steel F9 Male & Female Flanges | Duplex Steel K90941 RTJF Flanges |

| ASTM A182 Alloy Steel F9 Screwed Flanges | ASME SA182 Alloy Steel F9 Expander Flanges |

| WNR 1.7386 Puddle Flanges | Duplex K90941 Socket Welding Flange |

| Duplex Steel K90941 Weldo Flanges | Duplex Steel K90941 Nipo Flanges |

| UNS K90941 Long Welding Neck Flange | Duplex Steel K90941 Raised Face Flange |

| Alloy Steel F9 Spectacle Blind Flanges | Alloy Steel F9 BLRF Flanges Suppliers |

| Alloy Steel F9 High Hub Blinds Flanges | Alloy Steel F9 Flanges Facing Type & Finish |

| ASTM A182 Alloy Steel F9 Plate Flange | ASME SA182 Alloy Steel F9 Flat Flange |

| Alloy Steel F9 Long Weld Neck Flanges | DIN 1.7386 Threaded Flanges |

| UNS K90941 Forging Facing Flanges | Alloy Steel F9 Weld Neck Flanges A / B |

| WERKSTOFF NR. 1.7386 Loose Flanges | Alloy Steel F9 Welding Neck Flange |

Manufacturing Standards of Alloy Steel F9 Plate Flange

| ASME/ANSI B 16.5 | Blind Flange, High Hub Blind Flange, Slip on Flange, Socket Weld Flange, Ring Type Joint Flange, Welding Neck Flange, Lap Joint Flange, Threaded Flange |

|---|---|

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Blind Flange [Series A & B],Welding Neck Flange |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Slip on Flange, Threaded Flange, Welding Neck Flange, |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Plate Flange, Loose Plate Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Loose Plate With Weld Neck Flange, Blank Flange, Welding Neck Flange, Lapped Pipe End Flange, |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Plate Flange, Blank Flange, Welding Neck Flange, Loose Plate With Weld On Plate Collar, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Plate Flange, Blank Flange, Welding Neck Flange, Loose Plate With Weld On Plate Collar, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Screwed Boss Flange, Welding Neck Flange, Plate Slip-On Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641, 2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Manufacturing Process of Alloy Steel ASTM A182 F9 Flanges

Alloy Steel ASTM A182 F9 Flanges Application Industries

We produce full range of Alloy Steel F9 Flanges in every sizes, pressure / classes, dimensions to meet needs of customers. our products are well accepted by the majority of customers. it’s widely used in aerospace, shipbuilding, metallurgy, automotive instrumentation, petrochemical, food machinery, biological engineering In the field of environmental protection.

- Refineries

- Food Processing & Dairy

- Oil and Gas Industry

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Power Generation

- Specialty Chemicals

- Sea Water Equipment

- Gas Processing

- Chemical Equipment

- Heat Exchangers

- Petrochemicals

- Pharmaceuticals

- Condensers

ASTM A182 Alloy Steel F9 Flanges Inspection

We at Creative Piping Solutions ensures that all our materials go through strict quality tests before dispatching them to our clients. We conduct all necessary tests of Alloy Steel F9 flanges to assure the quality of deliver products to fit client’s projects and needs. NDT test used for ASTM A182 F9 Alloy Steel Flanges are Positive material identification (PMI), Penetrating liquids, Ferrite content, Hydrostatic test / hydro testing (pressure testing), Magnetic particles, Macrography, Micrography, Pneumatic pressure, Radiography. All of the listed test, the pressure testing is one of the most commonly specified, especially for mission critical fittings in the pipeline.

Alloy Steel F9 Flanges Packing & Forwarding

There are different ways of packing a Alloy Steel F9 Flanges, but two principles that are vital for any method to work prevent rusting and Sea transportation security. Our all products packed with seaworthy packing method then delivery to customers, usually the packing way include wooden box, wooden pallet. We make sure that it is seaworthy, strong, waterproof and easy for loading and unloading. All shipping and product details also stick to outside of package. Alloy Steel F9 Flange pack with environmental poly bags, and then in free fumigation wooden cases or wooden plate. ASME SA182 Alloy Steel F9 Flanges are packed in wooden corrugated boxes foiled in bubble wraps and plastic wraps.

ASTM A182 Alloy Steel F9 Flanges Export & Supply to below mentioned Countries

ASIA: Malaysia, India, Taiwan, Cambodia, Singapore, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Myanmar.

SOUTH AMERICA: Venezuela, Argentina, Bolivia, Colombia, Ecuador, Guyana, Paraguay, Uruguay, Brazil, Chile.

AFRICA: South Africa, Nigeria, Algeria, Angola, Libya, Egypt, Gabon, Sudan, Equatorial Guinea, The Republic Of Congo.

NORTH AMERICA: USA, Canada, Mexico, Panama, Costa Rica, Puerto Rico, Trinidad, And Tobago, Jamaica, Bahamas, Denmark.

EUROPE: UK, Netherlands, Russia, Norway, Germany, France, Italy, Spain, Ukraine, Belgium, Greece, Hungary, Albania, Austria, Finland, Ireland, Croatia, Slovenia, Malta, Switzerland, Slovakia, Czech Republic, Portugal.