Inconel 625 Flanges Manufacturer, ASTM B564 Inconel Alloy 625 Flange

ISO Certified Suppliers and Exporters of ASTM B564 Inconel 625 Flanges, UNS N06625 Slip-on Flanges, WNR 2.4856 Blind Flange, ASME SB564 Inconel 625 Weld Neck Flanges, werkstoff no 2.4856 Orifice Flanges, ANSI B16.5 Inconel 625 Square Flanges, Inconel Alloy 625 Backing Flange, UNS N06625 RTJ Flanges in India.

- Inconel 625 Flanges Specifications

- Inconel 625 Flanges Dimensions

- Inconel 625 Flanges Types

- Inconel 625 FF and RF Flanges Size Availability

- Inconel 625 Flanges Standard

- Manufacturing Standards of Inconel 625 Flanges

- Schedule / Class of Inconel 625 Flanges

- Equivalent Grades of Inconel 625 Flanges

- Chemical Composition of Inconel Alloy 625 Flanges

- Mechanical Properties of Inconel 625 Flanges

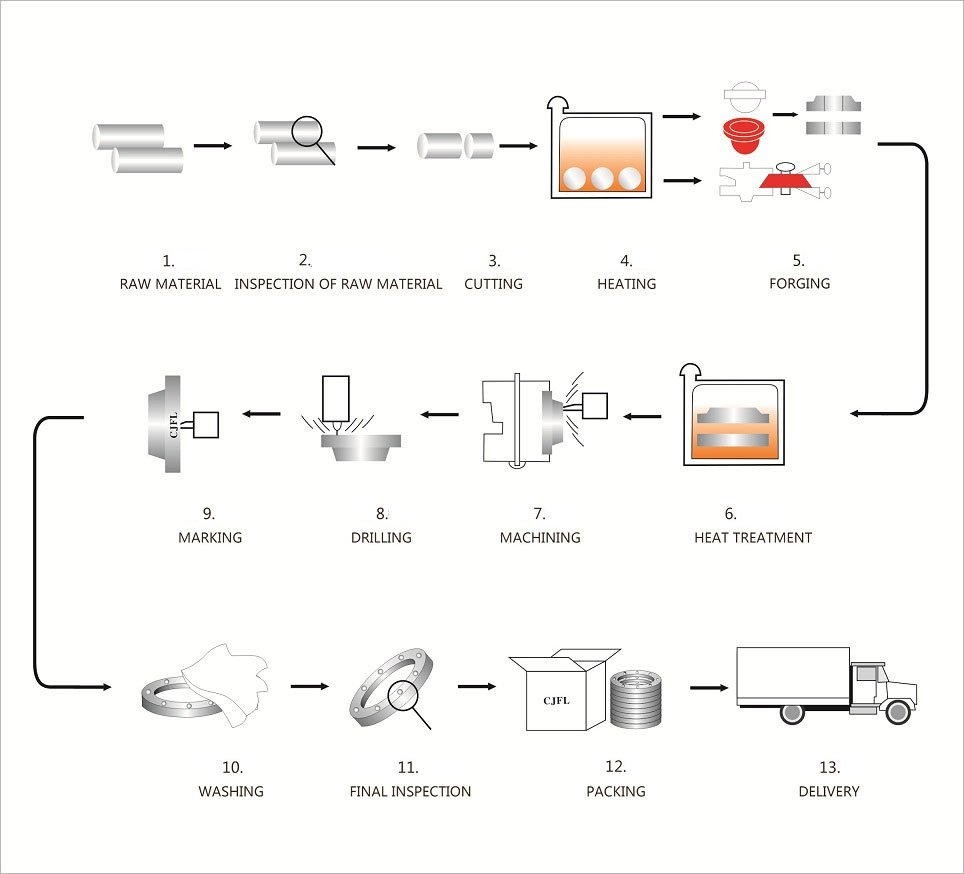

- Manufacturing Process of Inconel 625 Flanges

- Ready Stock of Inconel 625 Flanges

- Inconel Alloy 625 Flanges Application Industries

- Inconel 625 Flanges Inspection

- Inconel 625 Flanges Packing & Forwarding

Largest Stockists of Inconel 625 Forged Flanges, Werkstoff No 2.4856 SWRF Flanges, Inconel Alloy 625 Slip-on Flange, WNR 2.4856 Reducing Flanges, ANSI B16.5 Inconel Alloy 625 Industrial Flanges, JIS NCF 625 Weld Neck Flanges, DIN 2.4856 Socket weld Flange, GOST ХН75МБТЮ Threaded Flanges, AFNOR NC22DNB4MNiCr22Mo9Nb SORF Flanges, EN NiCr23Fe Long Weld Neck Flanges, BS NA 21 Lap Joint Flanges, ASME SB564 Inconel Alloy 625 RTJ Flanges.

Creative Piping Solutions one of the leading and most trusted Manufacturers and Suppliers of ASME SB 564 Inconel Grade 625 Flanges in India. This nonmagnetic, nickel-based alloy also offers a particularly broad working temperature range—from cryogenic to 2,000 °F (ca. 1,093 °C). Inconel 625 Flanges are considered as the right match for applications that involve nuclear and marine industries. Thanks to the modifications made within the alloy of the Inconel 625 Slip-on Flange, its properties like its creep resistance and weldability are enhanced.

Inconel 625 Spectacle Blind Flange is typically installed as a permanent device and is used to divide process piping systems. Alloy 625 Weld Neck Flanges are best utilized by clients whose applications are generally in condition wherein both the temperature are at extreme and pressure can rise to as high as 5,000 psi.

An advantage of using the Alloy 625 weld neck Flange is that they’re highly resilient, a property that’s achieved as they need the power to transfer or share the strain to the corresponding pipe to which it’s been welded to. Alloy 625 lap joint Flanges are used in conjunctions with stub end fittings and are designed for those operations during which regular dismantling is required. ASTM B564 UNS N06625 Blind Flanges issues simple access to the inside of the vessel it’s been bolted to. We are Offering reasonable prices incorporating large discounts against a variety of Inconel Alloy 625 Flanges.

Inconel 625 Flanges Specifications

- Specifications ASTM B564 / ASME SB564

- Size 1/2″ (15 NB) to 48″ (1200NB)

- Standards/Dimensions ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN

- Flange Class / Pressure 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64.

- Flange Face Type Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

- Flange Form SORF, WNRF, BLRF, SWRF, LAP Joint, Threaded, Reducing, Spectacle, etc

- Flange Connection Type Ring Type Joint, Lap-Joint Face, Raised Face, Flat Face, Large Male-Female, Small Male-Female, Large, Tongue & Groove, Small Tongue & Groove

- Flange Coating Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized

- Flange Test Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector

- Flange Origin Indian / West Europe / Japan / USA / Korean

ASTM B564 Inconel 625 Flanges Dimensions

Inconel 625 Flanges Types

ANSI B16.5 Inconel 625 Flange Forms & Availability

| Size | Products | |

|---|---|---|

| Sizes 1/8″ – 36″ Raised Face or Flat Face |

ASTM B564 Inconel Alloy 625 Slip-On Flanges | ASTM B564 Inconel Alloy 625 Threaded Flanges |

| ASTM B564 Inconel Alloy 625 Weld Neck Flanges | ASTM B564 Inconel Alloy 625 Socket Weld Flanges | |

| ASTM B564 Inconel Alloy 625 Blind Flanges | ASTM B564 Inconel Alloy 625 Reducing Flanges | |

| ASTM B564 Inconel Alloy 625 Lap Joint Flanges | ASTM B564 Inconel Alloy 625 Plate Flanges | |

| ASTM B564 Inconel Alloy 625 Orifice Flanges | ASTM B564 Inconel Alloy 625 Forged Flanges | |

| ASTM B564 Inconel Alloy 625 Ring Type Joint Flanges | ASTM B564 Inconel Alloy 625 Square Flanges | |

ASTM B564 Inconel 625 Flanges Standard

| American Steel Flanges Standard | Standard Code | ANSI ASME B16.5 | ASME – B 16.47 | ASME – B 16.36 | |||

|---|---|---|---|---|---|---|---|

| Standard Name | Welding neck flange, Blind flange, Slip on flange, Lap joint flange, Threaded flange, RTJ flange | Blind flange, Welding neck flange | Welding neck flange, Slip on flange | ||||

| German Steel Flanges Standard | DIN 2527 | DIN 2573 / 2576 | DIN 2673 | DIN 2641 / 2642 | DIN 28115 | DIN PN10, PN16 | DIN PN20, PN25 |

| Steel Blind Flanges, BLRF | Flat Flange for Welding (Slip On) | Loose Flanges and Rings for Welding (Slip On Flanges and Plain Collars) | Lapped / Loose (Lap Joint) Flanges Plain Collars | Long Neck Welding Flanges | Inconel 625 DIN PN 10 Flanges, Inconel 625 PN10 Flanges, Inconel 625 PN16 Flange | Inconel 625 DIN PN 25 Flanges, Inconel 625 PN20 Flanges | |

| Japanese Steel Flanges Standard | JIS B2220 | JIS B2291 | JIS 5K, 10K | JIS 16K, 20K | JIS 30K, 40K | ||

| Slipon plate flange (SOP), Slipon Hub (SOH), Lapjoint (LJ), Welding neck flange (WN), Socket Welding flange (SW), Threaded flange (TR)/ Itegral flange (IT) Blank flange (BL) | Slipon plate flange (SOP), Welding neck flange (WN), Lapjoint (LJ), Slipon Hub (SOH), Socket Welding flange (SW), Threaded flange (TR)/ Itegral flange (IT) Blank flange (BL) | Inconel 625 5K SORF Flanges, 10K SOFF Flanges | Inconel 625 16K Blind Flanges, 20K BLRF Flanges | Inconel 625 30K Slip on Flanges, 40K Blind Flanges | |||

| Italian Flanges Standard | UNI FLANGES | ||||||

| Plan flanges (2276, 2277, 2278, 6083, 6084) Lapped flanges (6088, 6089, 6090, 2999, 2300) Welding neck (2280, 2281, 2282, 2283, 2284, 2285, 2286) threaded flanges (2253, 2254) Blind flanges (6091, 6092, 6093, 6094, 6095, 6096, 6097) | |||||||

| British Standard Pipe Flanges Standard | BS 10 Table D | BS 10 Table E | BS 10 Table F | BS 10 Table H | |||

| Inconel 625 BS 10 Table D Flanges, Table D Pipe Flange | Inconel 625 BS 10 Table E Flanges, Table E Pipe Flange | Inconel 625 BS 10 Table E Flanges, Table E Flanges | Inconel 625 BS 10 Table E Flanges, Table E Pipe Flanges |

Manufacturing Standards of Inconel 625 Flanges

| ASME/ANSI B 16.5 | Blind Flange, High Hub Blind Flange, Slip on Flange, Socket Weld Flange, Ring Type Joint Flange, Welding Neck Flange, Lap Joint Flange, Threaded Flange |

|---|---|

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Blind Flange [Series A & B],Welding Neck Flange |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Slip on Flange, Threaded Flange, Welding Neck Flange, |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Plate Flange, Loose Plate Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Loose Plate With Weld Neck Flange, Blank Flange, Welding Neck Flange, Lapped Pipe End Flange, |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Plate Flange, Blank Flange, Welding Neck Flange, Loose Plate With Weld On Plate Collar, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Plate Flange, Blank Flange, Welding Neck Flange, Loose Plate With Weld On Plate Collar, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Screwed Boss Flange, Welding Neck Flange, Plate Slip-On Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641, 2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Schedule / Class of Inconel 625 Flanges

| Flange Schedule/Class | Flange Material | Flange Connection Type | Pipe Size – Pipe Flanges | Max. Pressure |

|---|---|---|---|---|

| ASME B16.5 Class 150 | Inconel 625 Flange | FNPT | 1/2″ | 150 psi |

| ASME B16.5 Class 150 | Inconel 625 Flange | Socket Weld | 1/2″ | 275 psi |

| ASME B16.5 Class 150 | Inconel 625 Flange | Welded | 1/2″ | 150 psi |

| ASME B16.5 Class 150 | Inconel 625 Flange | FNPT | 3/4″ | 150 psi |

| ASME B16.5 Class 150 | Inconel 625 Flange | Socket Weld | 3/4″ | 275 psi |

| ASME B16.5 Class 150 | Inconel 625 Flange | Socket Weld | 1-1/4″ | 275 psi |

| ASME B16.5 Class 150 | Inconel 625 Flange | Socket Weld | 1-1/2″ | 275 psi |

| ASME B16.5 Class 150 | Inconel 625 Flange | FNPT | 2″ | 150 psi |

| ASME B16.5 Class 150 | Inconel 625 Flange | Socket Weld | 2″ | 275 psi |

| ASME B16.5 Class 150 | Inconel 625 Flange | Socket Weld | 2-1/2″ | 275 psi |

| ASME B16.5 Class 150 | Inconel 625 Flange | Socket Weld | 3″ | 275 psi |

| ASME B16.5 Class 150 | Inconel 625 Flange | FNPT | 4″ | 150 psi |

| ASME B16.5 Class 150 | Inconel 625 Flange | Socket Weld | 4″ | 275 psi |

| ASME B16.5 Class 300 | Inconel 625 Flange | Slip On | 1/2″ | 720 psi |

| ASME B16.5 Class 300 | Inconel 625 Flange | Slip On | 1/2″ | 720 psi |

| ASME B16.5 Class 300 | Inconel 625 Flange | Slip On | 1″ | 720 psi |

| ASME B16.5 Class 300 | Inconel 625 Flange | Slip On | 1″ | 720 psi |

| ASME B16.5 Class 300 | Inconel 625 Flange | FNPT | 1-1/4″ | 720 psi |

| ASME B16.5 Class 300 | Inconel 625 Flange | Slip On | 1-1/4″ | 720 psi |

| ASME B16.5 Class 300 | Inconel 625 Flange | Slip On | 1-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Inconel 625 Flange | Slip On | 1-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Inconel 625 Flange | Slip On | 2″ | 720 psi |

| ASME B16.5 Class 300 | Inconel 625 Flange | Slip On | 2″ | 720 psi |

| ASME B16.5 Class 300 | Inconel 625 Flange | Slip On | 2-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Inconel 625 Flange | Slip On | 2-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Inconel 625 Flange | Slip On | 3″ | 720 psi |

| ASME B16.5 Class 300 | Inconel 625 Flange | Slip On | 3″ | 720 psi |

| ASME B16.5 Class 300 | Inconel 625 Flange | Slip On | 4″ | 720 psi |

| ASME B16.5 Class 300 | Inconel 625 Flange | Slip On | 4″ | 720 psi |

Equivalent Grades of ASTM B564 Inconel 625 Flanges

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4MNiCr22Mo9Nb | NiCr23Fe |

Chemical Composition of Inconel Alloy 625 Flanges

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

|---|---|---|---|---|---|---|---|---|

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015max | – | 5.0 max | 58.0 min | 20.0 – 23.0 |

Mechanical Properties of Inconel 625 Forged Flanges

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Inconel 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

Manufacturing Process of Inconel 625 Flanges

Ready Stock of Inconel 625 Flanges

| ASME SB564 Inconel 625 BLRF Flange | ASTM B564 Inconel 625 Raised Face Flanges |

| JIS NCF 625 Nipoflange | BS NA 21 Reducing Flanges |

| ANSI B16.5 Inconel 625 Pipe Flange | Inconel 625 Ring Type Joint Flanges |

| GOST ХН75МБТЮ Orifice Flange | Inconel 625 Spectacle Blind Flanges |

| Inconel 625 PN 10 Flange | PN 16 AFNOR NC22DNB4MNiCr22Mo9Nb Flanges |

| Inconel 625 Male & Female Flanges | EN NiCr23Fe RTJF Flanges |

| ASTM B564 Inconel 625 Screwed Flanges | ASME SB564 Inconel 625 Expander Flanges |

| WNR 2.4856 Puddle Flanges | BS NA 21 Socket Welding Flange |

| Inconel Alloy 625 Weldo Flanges | Inconel Alloy 625 Nipo Flanges |

| EN NiCr23Fe Long Welding Neck Flange | UNS N06625 Raised Face Flange |

| Inconel 625 Spectacle Blind Flanges | Inconel 625 BLRF Flanges Suppliers |

| Inconel 625 High Hub Blinds Flanges | Inconel 625 Flanges Facing Type & Finish |

| ASTM B564 Inconel 625 Plate Flange | ASME SB564 Inconel 625 Flat Flange |

| Inconel 625 Long Weld Neck Flanges | DIN 2.4856 Threaded Flanges |

| UNS N06625 Forging Facing Flanges | Inconel 625 Weld Neck Flanges A / B |

| WERKSTOFF NR. 2.4856 Loose Flanges | Inconel 625 Welding Neck Flange |

ASTM B564 Inconel Alloy 625 Flange Application Industries

We Produce full range of Inconel Alloy 625 Flanges in every sizes, pressure / classes, dimensions to meet needs of customers. Our Inconel 625 Flanges are well accepted by the majority of customers. it’s widely used in aerospace, shipbuilding, metallurgy, automotive instrumentation, petrochemical, food machinery, biological engineering In the field of environmental protection.

- Refineries

- Food Processing & Dairy

- Oil and Gas Industry

- Off-Shore Oil Drilling Companies

- Pharmaceutical Equipment

- Pulp & Paper Industry

- Power Generation

- Specialty Chemicals

- Sea Water Equipment

- Gas Processing

- Chemical Equipment

- Heat Exchangers

- Petrochemicals

- Pharmaceuticals

- Condensers

Inconel 625 Flanges Inspection

We at Creative Piping Solutions ensures that all our material go through strict quality test before dispatching them to our clients. We conduct all necessary test of Inconel Alloy 625 Flanges to assure the quality of deliver products to fit clients projects and needs. NDT test used for Inconel 625 Flanges are Positive material identification (PMI), Penetrating liquids, Ferrite content, Hydrostatic test / hydro testing (pressure testing), Magnetic particles, Macrography, Micrography, Pneumatic pressure, Radiography. All of the listed test, the pressure testing is one of the most commonly specified, especially for mission critical flanges in the pipeline.

Inconel 625 Flanges Packing & Forwarding

There are different ways of packing a Inconel 625 Flanges, but two principles that are vital for any method to work prevent rusting and Sea transportation security. Our all Inconel Alloy 625 Flanges packed with seaworthy packing method then delivery to customers, usually the packing way include wooden box, wooden pallet. We make sure that it is seaworthy, strong, waterproof and easy for loading and unloading. All shipping and product details also stick to outside of package. Inconel Alloy 625 Plate Flange pack with environmental poly bags, and then in free fumigation wooden cases or plate. Inconel Alloy 625 Flanges are packed in wooden corrugated boxes foiled in bubble wraps and plastic wraps.

Inconel Alloy 625 Flanges Export & Supply to below mentioned Countries

ASIA: Malaysia, India, Taiwan, Cambodia, Singapore, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Myanmar.

SOUTH AMERICA: Venezuela, Argentina, Bolivia, Colombia, Ecuador, Guyana, Paraguay, Uruguay, Brazil, Chile.

AFRICA: South Africa, Nigeria, Algeria, Angola, Libya, Egypt, Gabon, Sudan, Equatorial Guinea, The Republic Of Congo.

NORTH AMERICA: USA, Canada, Mexico, Panama, Costa Rica, Puerto Rico, Trinidad, And Tobago, Jamaica, Bahamas, Denmark.

EUROPE: UK, Netherlands, Russia, Norway, Germany, France, Italy, Spain, Ukraine, Belgium, Greece, Hungary, Albania, Austria, Finland, Ireland, Croatia, Slovenia, Malta, Switzerland, Slovakia, Czech Republic, Portugal.